A yoke plate is a device used to provide secure and reliable attachment point for the insulator. It is also known as a yoke bracket or a yoke clevis. Yoke plate has a specific shape and configuration that allows it to mount on the crossarm. It is from materials such as steel, aluminum and galvanized steel to provide resistance to corrosion. The yoke plate ensures proper alignment and spacing of the insulator to secure the attachment to the crossarm. They find use in applications such as overhead power lines, telecommunication lines and street lights.

Components of the yoke plate

Yoke plates have several components working together to meet the specific requirements. The design and configuration of the yoke plates vary depending on various factors. They include type of transmission line, conductor size, insulator type and specific project requirements. The following are the main components of a yoke plate.

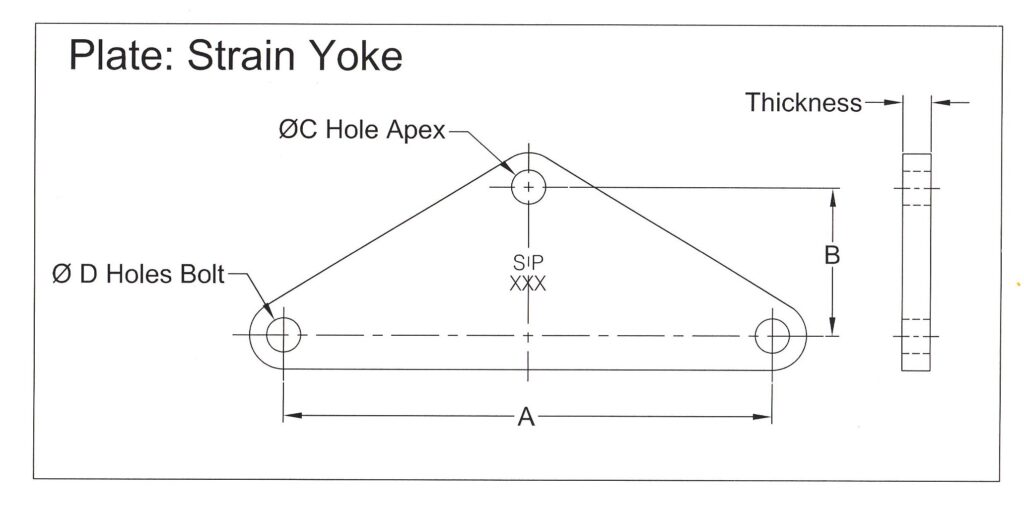

- Body – this is the main structure made of a flat or curved metal plate that provides the base for attachment.

- Holes – the holes allow it to be securely fastened to the crossarm using bolts, nuts and screws.

- Insulator pin holes – the yoke plate has insulator pin holes designed to help the attachment of insulators to the yoke plate.

- Hardware – the yoke clevis has extra attachment points for connecting other hardware.

Types of yoke plates

Yoke clevis work in overhead power transmission for secure and reliable connections. The type of yoke plate used for a particular application depends on various factors such as type of line, conductor size, insulator type and project requirements. The following are the common types of yoke plates used in power transmission lines.

Straight yoke plates – this plate has a straight configuration used when the insulator aligns in a straight line with the crossarm.

Double yoke plates – this type of yoke plate has two parallel arms that allow attachment of two insulators side by side. They are mostly used in applications such as multi-circuit transmission lines.

Adjustable yoke plates – this has a design with adjustable features such as sliding or rotating mechanisms. This allows for fine tuning the position of the insulator for proper alignment.

Offset yoke plates – this yoke plate works when the insulator needs to position at an angle to allow proper alignment with the conductor.

Triple yoke plates – this plate has three arms used to attach three insulators particularly in heavy duty applications.

Swivel yoke plates – this plate has a swiveling mechanism that allows the attached insulator to rotate or pivot to allow line sag or expansion.

Application areas of the yoke plates

Yoke plates ensure safe installation, alignment and mechanical stability of insulators in overhead power transmission and distribution systems. Yoke plates find use in various applications depending on the line design, conductor type, insulator configuration and project considerations. This is especially important to provide secure and reliable connections between conductors and insulators. The following are the common application areas of the yoke clevis.

- Overhead transmission lines – yoke plates provide a secure attachment point for insulators on the crossarms. This guarantees proper placement and spacing of the conductors.

- Long-distance power transmission – yoke plates help to support the conductors and insulators over long distances. They ensure reliable and effective power transmission across the grid.

- Multiple circuit transmission – the plates enable mounting of many insulators side by side. This eases the proper arrangement and spacing of conductors.

- High voltage transmission systems – the plates maintain the integrity and electrical insulation of the transmission lines to improve reliable connections.

- Power grid expansion – new transmission lines need yoke plates to connect the insulators. Yoke plates provide the necessary support for the conductors.

- Power distribution lines – yoke plates ensure the safe and reliable distribution of electricity.

Installation process of the yoke clevis

Installation process of the yoke plates should follow the regulatory standards of the industry and local standards. This should help improve safety and reliability of the applications. Additionally, it is advisable to consult with industry experts for guidelines. The following is a basic installation guide for the yoke plates.

- Prepare for the installation by making sure all the required tools and equipment are present. Ensure they are in good conditions to meet the required conditions.

- Prepare the crossarm by cleaning the surface to remove dirt, debris or corrosion that may hinder the installation. Ensure the crossarm is in good condition too support the yoke plates.

- Position the crossarm on the installation area and ensure it aligns with the conductor. Place the yoke plate on the selected location of the crossarm and align the mounting holes with the holes on the crossarm.

- Use fasteners such as bolts to tighten the connection and ensure the yoke plate is firmly attached to the crossarm.

- Attach the insulator to the selected attachment point on the yoke plates using insulator pins and fasten it to ensure secure connections.

- Inspect the installation to ensure proper alignment, attachment and spacing. Ensure it provides the necessary electrical performance.

Selecting the best yoke plate

The selected yoke plate should meet the specific requirements of the application. Yoke plates have different designs and types each with different pros and cons to select from. There are also different manufacturers and supplier with different types of yoke plates. Additionally, it is advisable to refer to industry experts for guidance on specifications, products and regulations. The following are the key factors to consider when selecting yoke plates.

- Evaluate the cost effectiveness of the plates by considering initial cost, quality and maintenance and repair costs.

- Ensure the design and configuration of the yoke plates match the specific requirements of your system.

- Determine the expected mechanical loads on the yoke plates and select the plat that can handle the loads.

- Consider the material used by checking its benefits and limitations of each material. Choose the most suitable material for your application.

- Check that the selected yoke plate meets the industry standards, regulations and guidelines for electrical requirements.

- Consider the voltage levels and ensure the selected yoke plate has the specific insulation properties. This is to ensure proper electrical performance and safety.

- Check the environmental conditions by considering factor such as temperature variations, humidity and pollution levels. The selected yoke plate should withstand these conditions.

- Determine the mechanical loads on the plates and select the yoke plate with sufficient load capacity to handle the loads.