Lashing wire clamps are types of hardware used on power lines to secure lashing wires to objects such as poles, messenger wires and insulators. The lashing wire is a thin, high tensile steel wire used to support and stabilize cables or conductors. A lashing wire clamp wraps around the structures to provide additional strength and stability. It has different components with gripping mechanisms to firmly hold the lashing wire. The lashing wire clamp is from materials such as steel or aluminum which help to prevent rust. They install using a wrench or socket wrench.

Components of wire clamps

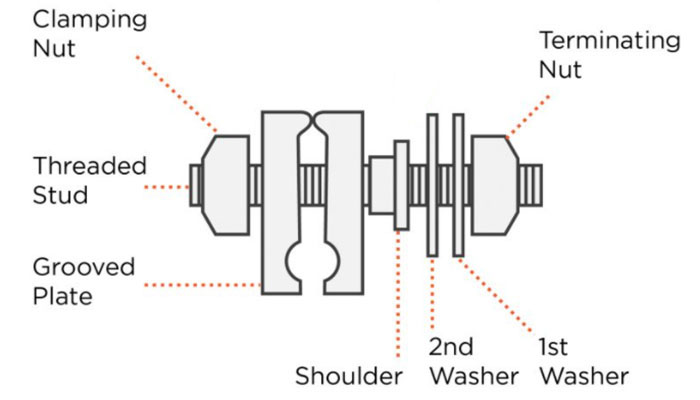

The components of the lashing wire work together to create a secure and reliable connection between the lashing wire and the supporting structures. They help to ensure stability and integrity of the power lines. The available components vary depending on they type of clamp and the manufacturer and are as discussed below.

- Body – this is the main part pf the clamp that holds the lashing wire in place made from material such as steel or aluminum. It helps to provide strength and durability.

- Jaws – these are two pieces made from steel or aluminum to prevent rust and corrosion. It helps to grip the lashing wire and ensure a safe and secure connection.

- Stud – this is a threaded rod passing through the jaws to secure the clamp in place.

- Fasteners – these include nuts, bolts and washers that prevent them from coming loose. They also help to distribute the load evenly on the wire.

Types of lashing wire clamps

Lashing wire clamps come in different designs for specific applications and requirements. The lashing wire clamps prevents the lashing wires from coming loose which may cause accidents. The following are the common types of lashing wire clamps for power transmission lines.

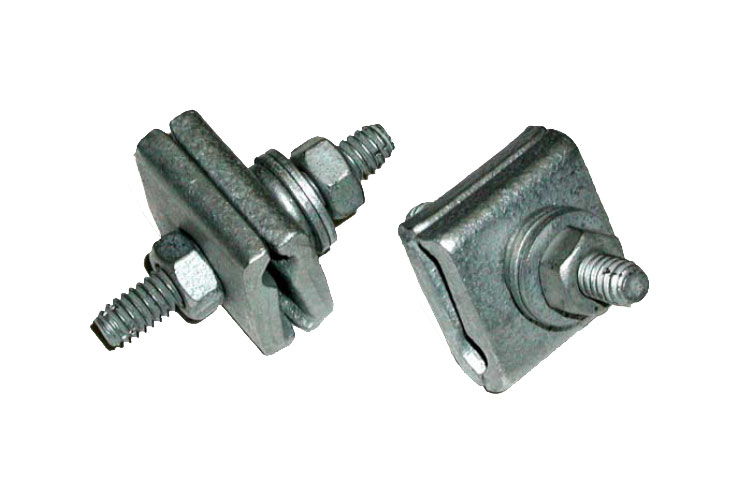

Type D lashing wire clamp – this is a three-piece clamp secured with two screws. It if from a design that works with 1/4-inch to 7/16-nch strand size.

Type E lashing wire clamp – this is a two-piece clamp secured with a single screw and works for 1/4-inch to 7/16-inch strand size.

Bug nut lashing wire clamp – this clamp has a bug shape made from galvanized steel to prevent rust and corrosion.

Bolt-type lashing wire clamp – this is a clamp that features bolts mechanisms to tighten the lashing wire.

Wedge-type lashing wire – this clamp utilizes a wedge-shape piece inserted between the lashing wire and the clamp body.

Application areas of wire clamps

Lashing wire clamps are versatile, have high strength and are able to provide secure connections. These factors make them essential components in the construction, maintenance and management of overhead power lines. The common application areas are as follows.

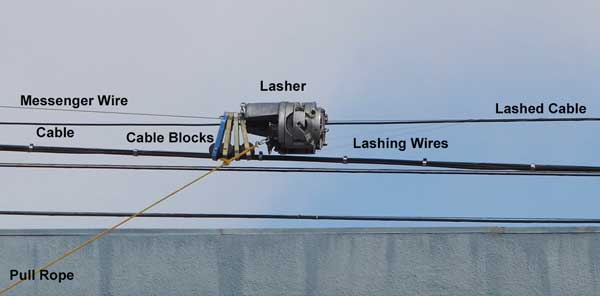

- Installation of aerial cables – lashing wire clamps work in the installation of the aerial cables such as fiber optic cables or communication cables to secure the lashing wire. This helps to ensure proper alignment and positioning of the cables.

- Overhead power lines – lashing wire clamps fasten the lashing wire around utility poles, transmission towers or other supporting structures. They help maintain the tension and stability of the lashing wire which support the cables.

- Cable management – lashing wire clamps work in cable management and support various industries. They organize cables in telecommunication, broadcasting and aerial cables.

- Power line maintenance – the clamps work on power lines when a faulty section of a power line needs to replacement or repair.

- Data centers and network – the clamps help to secure and support fiber optic cables or network cables within racks, cabinets and along cable management systems. They ensure proper organization, protection and strain relief for the cables.

- Security systems – lashing wire clamps help in the deployment of cameras, sensors or communication devices along utility poles. They secure the wiring necessary for these systems for proper installation and reliability.

Installation process of the lashing wire clamps

Some of the lashing wire clamps come with instructions for the installation process. The installation should adhere to all safety guidelines or regulations relevant to the installation process. Additionally, it is advisable to consult with the experts in the industry for guidelines whenever in doubt. The following are the basic steps followed during the installation process.

- Prepare all the tools and equipment required for the installation of the lashing wire clamp.

- Identify the location of the installation location for the lashing wire clamp on the supporting structure. Verify that the area is clean and free from any debris.

- Mount the lashing wire clamp on the desired location and align using the appropriate fasteners to secure the clamp to the structure.

- Take the lashing and wrap it around the supporting structure and ensure the wire positions evenly along the length of the structure.

- Insert the end of the lashing wire clamp into the gripping mechanism of the clamp. Tighten the bolt using necessary tools to apply tension on the lashing wire.

- Ensure the clamp is properly tensioned to provide support and stability to the cables or conductors.

- Inspect the installation to ensure secure connections and proper tensions of the lashing wire clamp. Cut off the excess lashing wire if it extends beyond the clamp.

Selecting the best wire clamp for cable support

The different designs and types of lashing wire clamps make it difficult to select the best for your application. You should consult with professionals in the electrical department to advice on the best lashing wire clamp what will meet the specific requirements of your projects. The following are some key factors to consider when selecting lashing wire clamps.

- Determine the suitable size and compatibility of the lashing wire clamp with the lashing wire and structure. Check the diameter of the lashing wire, maximum load capacity of the clamp and specific requirements for compatibility.

- Evaluate the materials of the clamp and consider factors like corrosion resistance, strength and durability.

- Determine the suitable type of lashing wire clamp by considering factors such as gripping mechanisms, tightening method, and specialized features for supporting weight.

- Consider factors like type of aerial cable, conductor, diameter of the lashing wire to understand the requirements of the installation.

- Ensure the selected lashing wire clamp complies to the industry standards that rule the selection of the clamps.

- Refer to manufacturer’s guidelines and specifications for the lashing wire clamp.