A stay insulator is a type of insulator used in low-voltage transmission lines. It is sometimes referred to as a guy or egg insulator. Stay insulators prevent electrical current from traveling via the guy wires. It electrically isolates the structure from the ground. A guy wire is a tensioned cable used to support utility poles and towers. It consists of materials such as high-quality porcelain and toughened glass. These materials have electrical insulating qualities and can tolerate severe environments. Its structure resembles a cylindrical or cone-shaped form with metal components. It is from a ceramic or composite insulator with connectors on each end for attaching to the guy wire. Stay insulators serve as silent guardians in the electrical grid. They ensure that the system operates safely and reliably. Stay insulators stop electrical leaks and maintain correct grounding.

Stay insulator design and structure

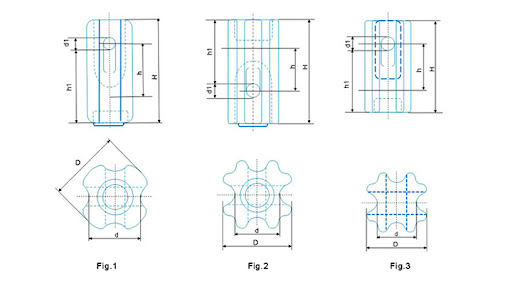

The design of the stay insulator varies based on its intended use, among other variables. Their design contributes to consistent electrical insulation, mechanical robustness, and long-term durability. The stay insulator’s basic design and structure are as presented here.

- Insulating material – stay insulators are from materials with excellent electrical insulation qualities. These include porcelain, glass, and composite materials such as polymer. The materials can also tolerate high electrical voltages.

- Core – they contain a hollow core that adds mechanical strength and stability to the insulator. It has designs to withstand compression, tension, and bending forces.

- Outer shell – the core has an outer shell constructed of the same insulating substance. This shell provides extra protection from environmental elements. This includes moisture, grime, and ultraviolet radiation.

- Fittings – stay insulators feature end fittings that connect to the guy wire and supporting structure. The fittings are from metal and may comprise threaded studs, clevises, or other hardware.

- Design features – Some insulators may have extra design characteristics such as ribs or sheds. They contribute to increased mechanical strength and improved electrical performance.

Common Features of a Stay Insulator

The primary function of the stay insulator is to provide mechanical support and electrical insulation for guy wires. Stay insulators ensure that electrical wires operate safely and efficiently. The following are the common characteristics of stay insulators.

- Electrical insulation – the insulators have designs to prevent electrical current from traveling along the stay wire. Insulation contributes to the integrity of the electrical distribution system, preventing power loss.

- Environmental resistance – Stay insulators can endure moisture, UV radiation, pollution, and temperature changes. This allows them to perform over lengthy periods of time.

- Pollution performance – Most insulators instal in polluted environments. Sheds, skirts, and hydrophobic coatings help to reduce pollutants.

- Mechanical strength – the insulators must be able to bear mechanical forces such as strain and compression. They aid to sustain the structure’s weight while also resisting wind loads, vibrations, and other factors.

- Corrosion resistance – Stay insulators face exposure to corrosive substances in the evironment. This include salt spray, industrial pollutants and chemicals. They aid to prevent against rust and corrosion, ensuring a longer service life.

- Easy installation and maintenance – The insulators should have designs for easy installation and maintenance. This is to save downtime and labor expenses. They also have conventional fittings and mounting options for secure installation.

- Compliance with standards – Stay insulators must adhere to industry standards and regulations. This is to assure safety, dependability, and interoperability.

What distinguishes a guy insulator from a strain insulator

Stay insulators and strain insulators serve distinct functions in electrical power networks. They also have unique designs to differentiate themselves. They both offer insulation and support in various applications. When in doubt, talk with professionals. The main distinctions between a stay insulator and a strain insulator are as follows.

- Function – stay insulators offer electrical insulation and mechanical support for guy wires. They support utility poles, transmission towers, and other similar structures. They ensure that the structure is electrically separated from the earth. Strain insulators serve to support and insulate electrical cables. They aid with the proper spacing and alignment of wires, preventing electrical arcing.

- Application – Stay insulators install at guy wire attachment locations to structures. They work on overhead power distribution and transmission wires. Strain insulators install at regular intervals along electrical lines to provide mechanical support. They work in overhead power transmission and distribution lines.

- Design – stay insulators have designs to endure electrical and mechanical loads. They have fittings on both ends for attaching to guy wires and support structures. Strain insulators can withstand mechanical tension or strain along electrical lines. The insulator comes in precise forms to withstand mechanical loads from the conductor.

- Functionality – stay insulators offer electrical insulation to prevent current leakage along the guy wires. They also give mechanical support to protect against wind loads and other external factors. Strain insulators offer mechanical support for electrical cables in tension. They disperse mechanical loads along the entire length of the cable. They also help to keep the conductors aligned.

Types of Stay Insulators

There are several types of stay insulators used on electricity transmission and distribution lines. They all have unique designs and features that are specific to the type of application. Stay insulators classify according to voltage rating and mounting technique. The following are the primary types of stay insulators used in transmission networks.

- Angle stay insulators – these insulators work on slanted sections of the guy wire that change direction. They aid to keep the clearance between the guy wire and the support structure. This is despite the mechanical forces acting on the angle point.

- Hybrid stay insulators – these incorporate various materials such as porcelain, glass, and polymers. These insulators have a good combination of characteristics for a variety of applications.

- Suspension Stay insulators – these are the most commonly utilized type of insulation. The design includes a long cylindrical insulator body and metal end fittings.

- Non-ceramic stay insulators – these consist of composite materials or polymers. They provide benefits like as lightweight construction, great pollutant resistance, and superior mechanical qualities.

- Strain Stay insulators – these are also known as tension Stay insulators. They have designs to withstand heavy mechanical loads. This is especially true in situations where the guy wires are under tension or strain.

- Insulated stay rods – these are useful in applications where the full length of the guy wire requires insulation. They have a solid or hollow insulating rod that attaches to the support framework.

- Clevis-type stay insulators – these have a U-shaped body with a pin that connects to the stay wire.

- Vibration dampening stay insulators – these are also called vibration control or anti-vibration stay insulators. They contribute to the reduction of vibrations generated by oscillations in the guy wire induced by winds or other factors.

Applications of Stay Insulators

Stay insulators are useful in a variety of applications, including electrical power systems and other sectors. This includes applications that need mechanical support and electrical isolation. They contribute to the safety, stability, and efficiency of many structures and systems. The following are frequent application areas for stay insulators.

- Transmission towers – stay insulators support and insulate guy wires linked to utility poles and transmission towers. They support and stabilize the structure.

- Overhead transmission lines – insulators install at the attachment points of guy wires along the overhead lines. They aid to keep the conductors in the right tension and alignment.

- Telecommunication lines – insulators work in the building of telecommunication towers and antennas. This is to support and insulate guy wires that provide structural stability.

- Railway electrification – they also work in train electrification systems, supporting the overhead catenary wires. Also, they provide electrical insulation between the wires and the supporting structures. Stay wires also help to keep the catenary wires tensioned and aligned, ensuring reliable train operations.

- Wind turbines – stay insulators work in the construction of wind turbine towers to insulate the guy wires. They help to endure wind loads and vibrations while maintaining electrical safety and reliability.

- Structural construction – They are also used in projects that need structural bracing, such as guy wires. They offer mechanical support for bridges, towers, and industrial structures.

- Antenna towers and broadcast towers – insulators work in the construction of antenna towers, broadcast masts, and other structures. They contribute to the reduction of radio frequency signal interference.

Frequently asked Questions

A stay insulator is a component found in electrical systems that provides both electrical insulation and mechanical support. They install at the point where guy wires connect to utility poles or transmission towers.

Stay insulators come in various types including porcelain, glass, composite and hybrid insulators. Each type offers specific advantages like electrical properties and mechanical strength.

Stay insulators are from insulating materials like glass, porcelain, or composites. These materials help to keep electrical current from flowing through the guy wires. They also provide great electrical resistance, which isolates the supported structure from the ground.

Consider the voltage rating, mechanical load requirements, environmental factors, and pollution performance.