A spool tie is a type of hardware used to attach conductors to the supporting structures such as towers or poles. Also, it consists of a metal or composite material that forms a spool-like shape to allow the conductor to wound around it. Its main purpose is to provide flexibility and allow for the expansion and contraction of the conductor. This is important to maintain the integrity of the transmission line. They mainly help to ensure the conductors do not expand and contract due to temperature changes. Spool tie is from durable materials that help to ensure the longer service life and resistance to environmental factors. This guide helps to uncover how the spool tie enhance power infrastructure resilience in South American nations. Examples include helical spool tie, compression tie and composite tie. They find use in applications like transmission lines and telecommunication towers.

Key features of spool tie

Spool ties have various features that promote their suitability in various applications. Each of these factors promote the effectiveness of the tie in different ways. The following are the key features of the spool tie.

- Secure conductor attachment – the tie attaches the conductors to the supporting structures. This helps to ensure the conductor remains in place to reduce the risk of sagging.

- Corrosion resistance – they also have various features of coatings materials that resist corrosion. This helps to maintain the structural integrity of the ties and prevent degradation.

- Easy installation – the include the process of securing conductors to support the structures. This also helps to ensure the simplest process of installation with no complications.

- Insulating properties – they may also have insulating materials to prevent electrical contact between the conductor and the supporting structure.

- Versatility – they are flexible enough to find use in various applications. This is including transmission lines, renewable energy projects and urban power grids.

- Flexibility – this is the main feature that allows them to accommodate thermal expansion and contraction of conductors.

- Materials – they manufacture from durable materials such as aluminum, steel or composite materials. These materials help to ensure longer service life.

- Vibration damping – they also have designs to dampen vibrations in the transmission lines. This may be from factors like wind and other forces.

Selection and installation of spool tie

The selection process of spool ties helps to ensure the reliability and longevity of overhead transmission lines. It involves considering several factors to help make an informed decision. These factors include conductor size and type, environmental conditions, vibration and wind loads, materials durability and installation ease. The installation process should ensure the stability and reliability of transmission lines. The following is a general installation process of the spool ties.

- Preparation – gather all the tools and materials required for the installation. These include spool ties, conductor, insulating materials, wrenches and safety gear.

- Site inspection – perform a thorough inspection of the site to ensure the supporting structures are in good condition.

- Conductor preparation – unwind the conductor from the spool tie to ensure it is free from damage. install any insulating materials on the conductor based on the requirements.

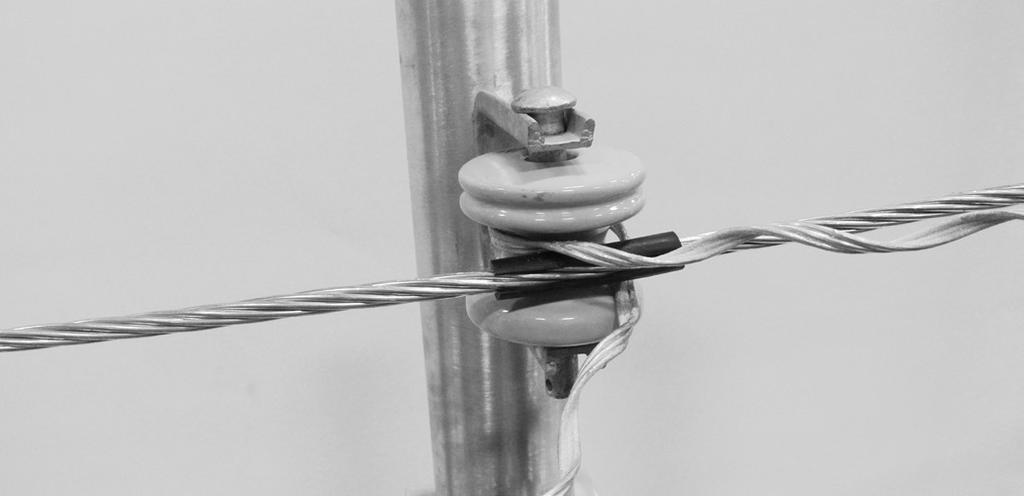

- Position the spool tie – place the spool tie on the supporting structure at the desired location. Ensure it is properly aligned and securely fastened to the structure using the suitable hardware.

- Wrap the conductor – wrap the conductor around the spool tie. This is to provides the required tension and maintain the desired configuration.

- Secure the conductor – use the available attachment mechanisms to secure the conductor in place on the spool tie.

- Tension verification – check the tension of the conductor to ensure it meets the recommended levels.

- Repeat the process – repeat the installation process for each of the entire transmission line. Check each spool tie and conductor connection for any signs of issues.

- Document the installation – maintain detailed records of the installation. This is including the type and specifications of spool ties used.

Maintenance and inspection of spool tie

Proper and regular maintenance and inspection of the spool ties helps to ensure the reliability and longevity. It also helps to identify and address potential issues that may lead to failures or accidents. Additionally, the various environmental conditions of the region influence the frequency. The following is a basic guide on the maintenance and inspection of spool ties in South America.

- Conduct regular visual inspections of all spool ties to look for signs of wear, corrosion or damage.

- Check the tension of the conductors secured by the spool ties to ensure optimal performance.

- Consider the specific environmental conditions at each transmission line location. Some of the regions may require more frequent inspections for signs of corrosion.

- Apply corrosion resistant coatings to spool ties. Regularly inspect and maintain them to ensure effective corrosion prevention.

- Check the integrity of the attachment hardware to ensure they are properly fastened and not corroded.

- Inspect the insulating materials to ensure they are intact and providing the necessary electrical insulation.

- Monitor the impact of spool ties and look for signs of fatigue or stress caused by oscillations.

- Maintain detailed records of the activity including adjustments and any observations made.

Comparative analysis of spool ties in South America

A comparative analysis involves evaluating and analysing different types of spool ties based on various factors. Some include the types, designs, brands and size. It also helps to ensure you select the right and correct type of spool tie specific to your application needs. Additionally, it is advisable to consult with industry professionals to ensure proper selection. The following are the factors to include in a comparative analysis in South America.

- Material durability – evaluate the performance of spool ties made from traditional materials like aluminum or steel. also, assess the suitability of spool ties made from composite materials such as fiberglass. Consider their durability in the diverse weather conditions in the region.

- Vibration damping – compare spool ties in their ability to dampen vibrations caused by wind to help maintain the stability.

- Cost effectiveness – analyse the cost effectiveness of spool ties considering both upfront costs and long-term benefits.

- Applicability to terrain – evaluate how well spool ties adapt to various terrains in south America. Consider the suitability for both urban and rural environments.

- Corrosion resistance – compare the corrosion resistance of coated spool ties with uncoated ones.

- Thermal expansion and contraction – evaluate the flexibility of spool ties in thermal expansions and contraction aspects of conductors.

- Resistance to environmental factors – assess how well the spool ties withstand high humidity and temperatures. Consider the impact of these factors on the longevity and performance of different types of ties.

Certifications and standards in South America

There are various standards and certifications that govern the use of spool ties in South America. They also help to ensure the quality, safety and compatibility of the spool ties. Also, it is important to ensure the selected spool tie meets the necessary standards and regulations. The following are the certifications and standards of spool ties in South America.

- IEC standards – these are standards that ensure the spool ties demonstrate adherence to international norms. It also helps to ensure the consistency in design and performance.

- ASTM standards – these are standards that provide assurance of quality and reliability of the tie.

- ISO certifications – this indicates the manufacturers quality management system meets international standards. They also help to ensure the quality of the manufacturing process for spool ties.

- Regional electrical codes – each south American country has their own set of electrical codes and standards. They help to ensure the safety and reliability of the electrical systems.

- Environmental management system certification – this standard ensures the manufacturer adheres to environmental management standards.

Regional market for spool tie in South America

There are various factors that shape and influence the regional market for spool tie in South America. It important to conduct market research, check industry publications and local business sources. Some of these factors include:

- Infrastructure development – there is high demand from the increased infrastructure development in South America.

- Government regulations – adherence to safety and quality standards may influence the types of spool ties used in transmission lines.

- Economic factors – these affect the volume of construction and maintenance activities that impact the demand for spool ties.

- Renewable energy projects – development of wind and solar power contributes to the demand for spool ties in the region.

- Technology and innovation – advancements in spool tie technology and the introduction of innovative materials may influence the market trends. This may include products that offer improved durability, flexibility and ease of installation.

Frequently asked questions

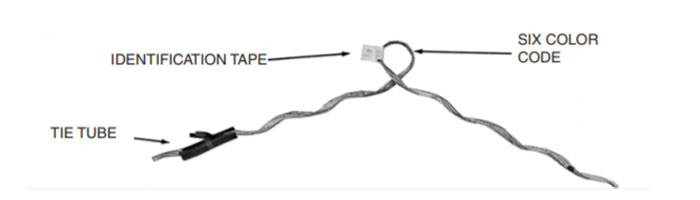

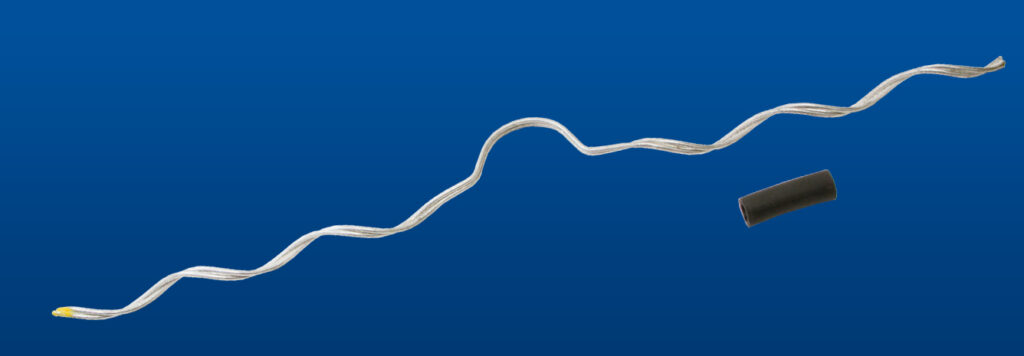

Spool ties are pre formed wires used to secure conductors to spool insulators on overhead transmission lines. They provide faster and easier installation, protection against conductor damage and superior electrical performance.

Spool ties contribute to tension control through providing increased grip, consistent tension, reduced vibration, improved weather resistance and easier inspection.

spool ties are from various materials such as aluminum, steel, fiberglass or other materials. They help to provide weather resistance, reduce friction and provide high strength.