A top tie is a special sort of fastening or securing mechanism used to connect the conductor to the insulator. The design ensures low electrical resistance and mechanical stability. This serves to ensure that the transmission line operates safely. The top ties’ primary role is to hold the conductor in place and keep it attached to the insulator. It also ensures that the conductor is at a safe distance from the pole to avoid electrical arcing. Top ties prevent movement and friction, which might result in wear over time. Top ties comprise of materials that are strong, long-lasting, and resistant to corrosion. These materials include galvanized steel, aluminum, and composite materials. They perform many duties in the electrical transmission operations.

Fittings utilized with a top tie in overhead transmission lines.

A top tie operates in conjunction with many accessories to assure the transmission system’s stability, safety, and efficiency. Each of these accessories serves a specific function in overhead transmission lines. The combination helps to reduce maintenance requirements and extend the system’s lifespan. The following are the most typical accessories used with top ties in overhead transmission lines.

- Spacers – these help to maintain the proper spacing between conductors in a multi-conductor bundle. This prevents the conductors from clashing and ensures consistent electrical performance.

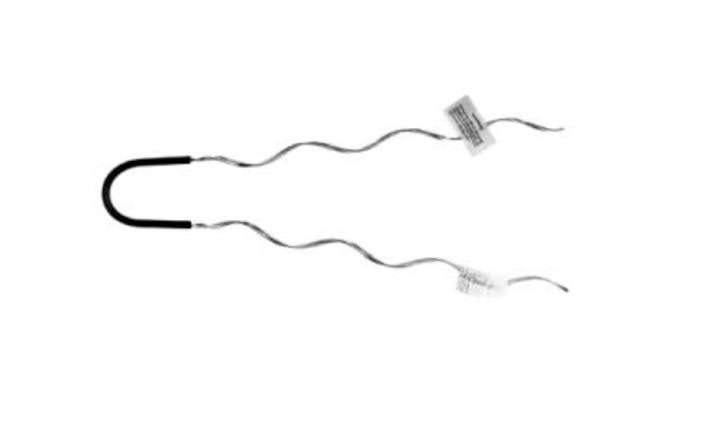

- Armor rods – these wrap around the conductor at the point of attachment to protect it from abrasion and mechanical stress.

- Insulators – these components support and electrically isolate the conductors from the poles. Common types of insulators include pin-type, suspension and post insulators.

- Vibration dampers – these are devices installed to reduce the amplitude of conductor vibrations.

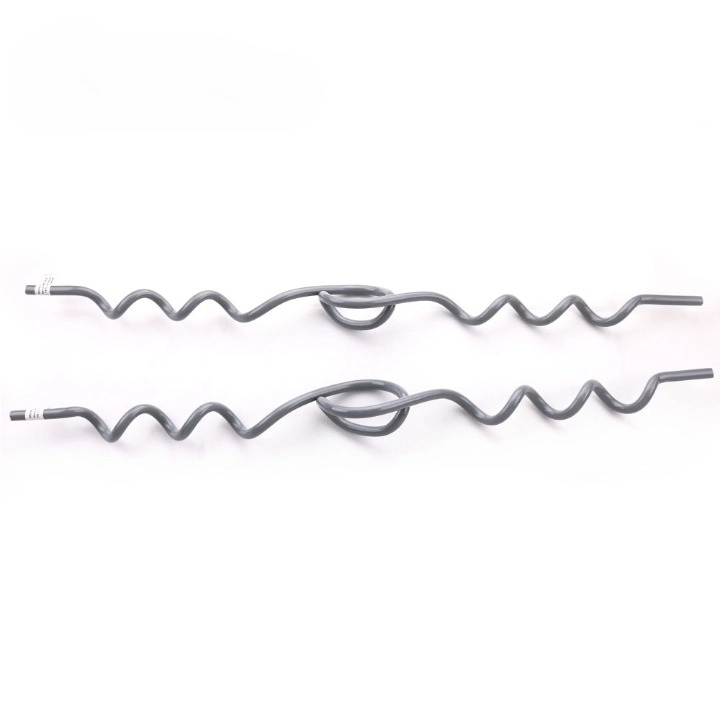

- Preformed ties – these have designs to fit specific conductor sizes and insulator types. This is to provide a secure and uniform attachment.

- Line guards – these offer protection against mechanical damage and electrical stress. This is especially in areas with high pollution.

- Bird guards – these serve to prevent birds from perching on insulators and causing contamination.

- Clamps and brackets – these help to secure the insulators and other accessories to the tower structure.

- Arcing horns – these are protective devices used to divert electrical arcs away from insulators during lightning strikes.

- Corona rings – these help to distribute the electric field around the insulator and reduce corona discharge.

Top Tie Coatings and Treatments

Top ties face a variety of environmental and mechanical stressors. Coatings and treatments improve longevity, corrosion resistance, and performance. The coatings and treatments used vary by the transmission line’s specific environmental conditions and mechanical needs. The following are the most frequent coatings and treatments for top ties.

- Aluminum coating – this includes spraying molten aluminum onto the top tie’s surface to create a protective layer. This layer provides excellent corrosion resistance ideal for coastal or polluted areas.

- Polymer coatings – epoxy coatings provide a tough, chemical-resistant barrier that protects the top tie from corrosion and mechanical damage. Polyester coatings apply as powder and then cured to form a durable and UV resistant coating.

- Galvanization – this includes hot-dip galvanizing where the tie inserts into molten zinc. This proccess is to form a corrosion-resistant coating. It also includes applying a zinc coating through an electrochemical process to provide a smooth finish.

- Phosphate treatment – this is a chemical treatment that involves applying a phosphate coating. The coating enhances the adhesion of coatings. It also provides a degree of corrosion resistance.

- Anodizing – this is an electrochemical process that increases the natural oxide layer on aluminum top ties. This provides enhanced corrosion resistance and surface hardness.

- Zinc-aluminum coatings – these are coatings applied through thermal spraying or dipping. It combines the benefits of zinc and aluminum. They provide superior corrosion resistance for use in harsh environments.

- Painting – this is applying specialized paints to top ties to provide a layer of protection against corrosion and UV degradation.

- Passivation – this is a process that enhances stainless steel top ties by removing surface contaminants. The process also promotes the formation of a protective oxide layer.

Technical standards for top ties

Technical specifications for a top tie provide instructions and information for its application and requirements. They vary according to the application, conductor type, insulator design, and ambient conditions. The technical guidelines ensure that the top tie provides enough mechanical support, electrical conductivity, and environmental durability for overhead transmission lines. The following are the technical specifications for top ties.

- Mechanical properties – top ties should have tensile strength and provide flexibility. This is to be able to withstand forces exerted by the conductor and environmental conditions.

- Dimensions and size – the length of the top ties varies depending on the insulator and conductor size. The diameter should match the conductor size to ensure secure fit and handle mechanical and electrical load.

- Material composition – top ties are from various materials including aluminum alloy, galvanized steel and copper. Each of these materials provide several benefits such as high strength, corrosion resistance and durability.

- Coating and surface treatment – these include galvanization, aluminum coating and polymer coatings. They include specifications for the thickness of the zinc coating, thermal spraying and type of epoxy of polyester coatings.

- Compatibility – the specifications should provide details for conductor compatibility and insulator compatibility.

- Electrical properties – this includes details for current carrying capacity and electrical resistance. The current capacity should match or exceed the conductor’s current carrying capacity. The top tie should have low electrical resistance to reduce power losses.

- Environmental resistance – the top tie should be able to withstand factors that lead to corrosion. They should also be UV resistant to ensure longevity under sunlight exposure.

Industry developments and updates for top ties

Recent improvements in the industry for top ties center on increasing their durability and efficiency. The industry strives to improve the performance and dependability of top ties for efficient use in overhead lines. Also, staying up to date is critical to ensuring that the applications perform optimally. The following are the major developments and updates for top ties.

- Improved coatings and treatments – this is the development of hybrid coatings that combine different coating materials. This is to enhance performance characteristics like higher corrosion resistance and longevity. There are also innovations in coatings that can repair minor damages automatically. This helps to maintain their protective properties.

- Enhanced design and engineering – this is designing top ties with aerodynamic shapes. Such shapes reduce wind-induced vibrations. Preformed top ties provide a more secure fit since there are specific to conductor sizes.

- Advanced materials – development of high strength composite materials provides durability and corrosion resistance. Use of Nanocoatings enhances surface properties to provide superior resistance to corrosion and wear.

- Environmental adaptations – there is development of environmentally friendly coatings that reduce the ecological footprint of manufacturing processes.

- Smart monitoring and diagnostics – this includes embedding sensors in top ties to track stress, temperature and electrical load in real time. Leveraging the IoT to collect and analyse data from many top ties eases management and fault detection.

- Cost effective solutions – use of advanced manufacturing techniques reduces costs and improves the precision of top tie components. Designing modular top tie systems that can be easily replaced reduces labor costs and downtime.

Troubleshooting top ties on overhead transmission cables

Troubleshooting a top tie entails many steps for identifying and resolving various faults. This repair contributes to the longevity and dependability of top ties in overhead wires. Also, perform professional maintenance and inspections on a regular basis. The following is a basic troubleshooting tutorial for top ties.

- Mechanical testing – use a tensile tester to check the mechanical strength of the top tie. Compare the results with manufacturers specifications. Bend the top tie to see if it maintains its integrity without breaking.

- Electrical testing – measure the electrical resistance across the top tie to ensure its within acceptable limits.

- Visual inspection – check for signs of rust, oxidation or other forms of corrosion on the top tie and its coatings. Check for physical damage and loose connections.

- Environmental analysis – check for UV damage and signs of pollution-related damage. This is including deposits from industrial environments.

- Remedial actions – this includes cleaning, tightening, replacing damaged components and re-coating.

- Advanced diagnostics – use thermal imaging to detect hotspots that can state poor electrical connections. Conduct vibration analysis to identify issues that could lead to mechanical fatigue.

- Sensor data review – review data from embedded sensors to check for unusual stress or load patterns. Check for temperature anomalies the might show electrical or mechanical issues.

- Documentation – document all findings, test conducted, and actions taken. Provide recommendations for ongoing maintenance.

Frequently asked questions

A top tie is a fastening mechanism used to secure the conductor to the insulator on the top of utility pole.

Common accessories include insulators, spacers, armor rods, vibration dampers, preformed ties, line guards, corona rings and clamps and brackets.

Common coatings and treatments include galvanization, aluminum coating, polymer coatings, phosphate treatment, anodizing and zinc-aluminum coatings.