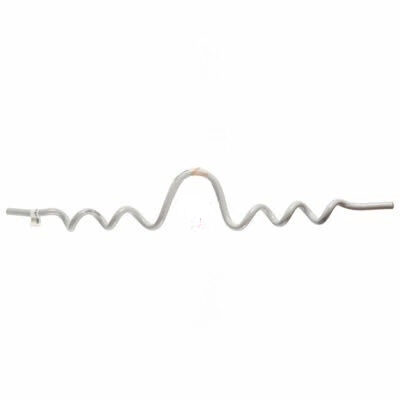

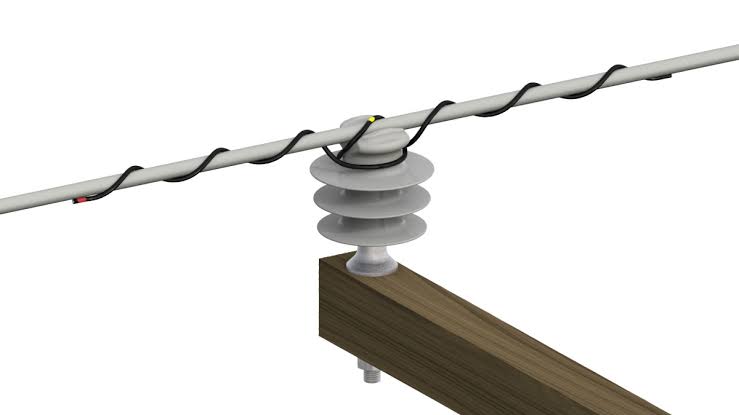

A top tie is a piece of hardware that secures the conductor to the insulator on the top side of a pole. It is a component that helps to assure the stability and dependability of the transmission line. The top tie has designs to loop around the conductor and attach it to the insulator. This helps to keep the conductor from shifting or coming loose due to wind. The top tie bears the conductor’s mechanical load, which includes weight and the extra tension. Top ties can be pre-formed, hand-tied, or helical ties. They comprise of materials that are conductive, strong, durable, and corrosion resistant. These materials include aluminum, galvanized steel, and composite materials.

Purpose of a top tie

Top ties serve many uses in overhead transmission lines and electrical systems. They help to ensure the system’s reliability and safety. They ensure electrical continuity, support mechanical loads, and ease installation and maintenance. Top tie functions include the following:

- Maintaining electrical continuity – the top tie ensures continuous electrical conductivity for efficient power transmission. It prevents interruptions in power supply that can be from loose conductors.

- Supporting mechanical loads – top ties have designs to bear the mechanical load of the conductor. This might include weight and extra stresses. It is capable of handling the tension from the conductor and ensure stability.

- Securing the conductor – the primary function of the top tie is to attach the conductor to the insulator and ensure it remains in place. It also prevents the movement of the conductor due to wind or ice.

- Enhancing safety – proper installation of top ties enhances the safety of transmission lines. This is by reducing the risks related to sagging or detached conductors.

- Installation and maintenance – top ties have designs that allow easy installation and maintenance. This is to ensure the efficient setup and longevity of the transmission line. Simplified installation and maintenance reduces time consumed and labor costs.

- Extended lifespan – use of high quality top ties contribute to the longevity and durability of the transmission line. They also reduce the need for frequent maintenance and replacements.

Performance features of a top tie

The performance features of a top tie are critical to its effectiveness and dependability. The qualities ensure that the top tie can perform its intended functions in a variety of circumstances. Top ties also guarantee that conductors are securely attached to insulators, which preserves transmission line dependability and efficiency. The following are the primary performance characteristics of a top tie.

- Electrical conductivity – this is the capacity of the top tie to conduct electricity with minimal resistance. It also reduces energy losses and maintains stable power delivery.

- Corrosion resistance – the top tie should be resistant to elements like moisture, salt, and chemicals. Corrosion resistance ensures the longevity of the top tie in various environmental conditions.

- Temperature resistance – this is the ability of the top tie to maintain performance and structural integrity across a wide range of temperatures.

- Tensile strength – this is the greatest stress a top tie can withstand without breaking. It ensures the tie can handle the mechanical loads from the conductor.

- UV resistance – the ability of the top tie to withstand prolonged exposure to UV radiation without degradation. This is important to maintain material properties and structural integrity over time.

- Mechanical impact resistance – this protects the integrity of the top tie to prevent accidental failures during maintenance.

- Vibration resistance – this prevents mechanical fatigue and potential loosening to the conductor.

- Load distribution – this is the tie’s ability to distribute mechanical loads across the conductor and insulator interface.

- Dimensional stability – this is the ability of the tie to maintain shape and size under various conditions. It ensures the consistent fit and secure attachment to conductors and insulators.

- Environmental durability – the top tie should be able to perform under diverse environmental conditions. This is to ensure the long term performance and reduce the need for replacements and maintenance.

Testing processes for top ties

Testing top ties is critical to ensuring their longevity and safety for overhead transmission lines. The top ties go through a series of testing to guarantee that they are robust and capable of carrying out their intended activities. The following are the most common tests performed on top ties.

- Corrosion resistance test – this is to assess the tie’s ability to resist corrosion in harsh environmental conditions. It involves exposing the tie to a corrosive environment to ensure longevity.

- Fatigue test – this is to check the top tie’s durability under repeated loading and unloading cycles. It involves placing the top tie to cyclic loading to simulate the stresses it will experience.

- Tensile strength test – this aims to determine the greatest load a top tie can withstand before breaking. It involves applying increasing tensile forces until the top tie fails. This is to ensure the top tie can handle mechanical loads exerted by the conductor.

- Electrical resistance test – measure the electrical resistance of the top tie to ensure it does not introduce resistance. Use precise instruments to measure the resistance of the top tie.

- Vibration test – test the top tie’s ability to resist vibrations caused by wind, traffic or other sources. Subject the top tie to controlled vibrations and track its structural integrity.

- Temperature cycle tests – this is to determine the top tie’s performance under extreme temperatures. It involves exposing the top tie to cycles of high and low temperatures. This is to ensure it can maintain its mechanical and electrical properties.

- UV resistance test – this test is to assess the top tie’s resistance to UV radiation. The method involves exposing the top tie to intense UV light for an extended period. This test ensures the top tie can withstand exposure to sunlight without degradation.

Application settings for top ties

Top ties serve many purposes in overhead transmission and distribution lines. They provide stability, safety, and efficiency for power delivery systems. Also, it is advisable that you choose the best tie for your unique application needs. The following are the applications for a top tie.

- Utility poles and towers – the ties install on poles to hold conductor sin place. They ensure the structural integrity and proper functioning of the power delivery infrastructure.

- Overhead distribution lines – the top ties serve in lower voltage distribution networks. This is to provide stability and reduce the risk of conductor movement in distribution networks.

- Substation connections – they also serve in substations to secure busbars to insulators. They maintain electrical connections for efficient power distribution.

- Overhead transmission lines – top ties secure conductors to insulators on high voltage transmission lines. They ensure stable and reliable power transmission over long distances.

- Renewable energy installations – they find use in wind farms and solar power plants to secure transmission lines. This is to ease integration into the power grid.

- High-capacity transmission lines – top ties serve in these applications to secure large conductors carrying electrical loads.

- Railway electrification – the ties secure the overhead contact lines to ensure reliable power delivery to electric trains.

- Urban and industrial power networks – they also help to maintain the stability of power distribution networks.

Regulations and standards for top ties

Several standards and regulations exist to ensure the top tie’s safety, dependability, and performance. These standards come from a variety of organizations. This is including international, national, and industry-specific authorities. Additionally, sticking to these guidelines ensures that the top ties meet the appropriate requirements. The following are the main criteria and regulations governing the use of top ties.

- IEEE standards – this provides guidelines for testing and information on the mechanical loads the top ties need to withstand.

- American national standards institute (ANSI) – this standard includes test methods for electrical power insulators and top ties.

- International electrochemical commission (IEC) – this standard covers the mechanical and electrical needs for various fittings. It specifies test such as tensile strength, fatigue and environmental resistance.

- Industry-specific standards – this provides specifications for the construction of overhead power lines including top ties.

- Regulatory compliance – this includes safety standards for the installation, operation and maintenance of electric power generation.

- Testing and certification – this includes Underwriters Laboratories and National Electrical Manufacturers Association. They include principles of testing and certification for mechanical and electrical performance.

Frequently asked questions

A top tie is a hardware component used to secure a conductor to an insulator on the top side of a pole. It ensures the stability and reliability by preventing movement and maintaining electrical continuity.

Top ties go through a variety of environmental simulation tests that include humidity, temperature, and corrosive chemicals to guarantee they can resist real-world circumstances.

Top ties are from materials like galvanized steel, aluminum and composite materials.

Tensile strength determines the greatest load a top tie can withstand before breaking. It also ensures it can handle the mechanical stresses from the conductor.