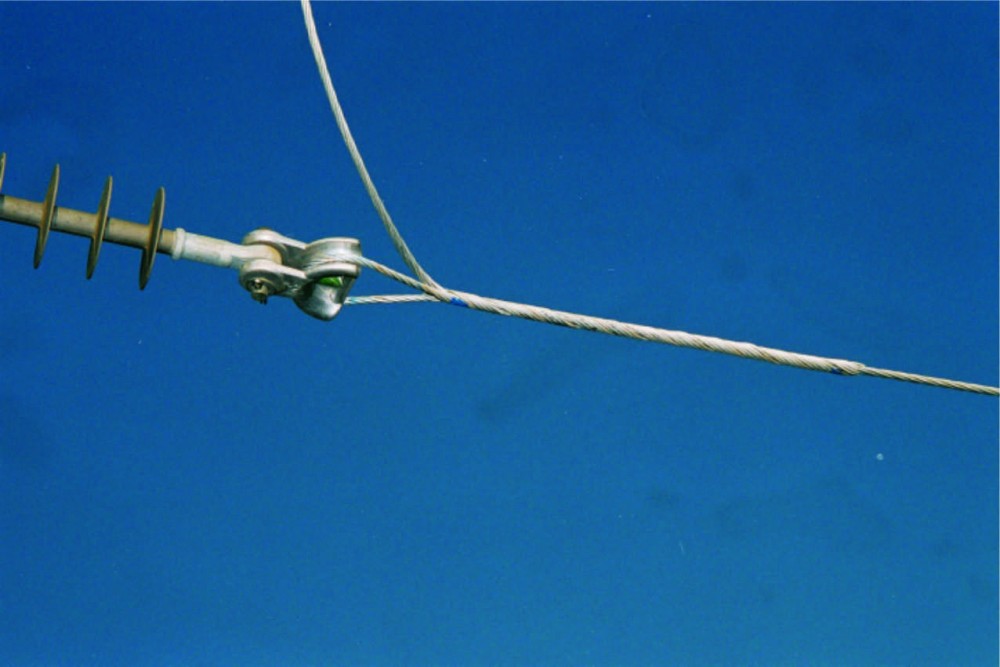

Thimble clevis is a component used in overhead transmission lines. It works in the construction and installation of the conductor suspension system. It attaches the conductor to the supporting structure likes poles and towers. Thimble clevises creates a secure and reliable connection between the conductor and the suspension insulator. The conductor passes through the thimble which provides mechanical support. It also protects the conductor from abrasion or damage caused by direct contact with the metal clevis. It helps in distributing the load evenly across the conductor and facilitates the attachment of the conductor to the hardware using bolts or other fasteners.

Components of thimble clevis

Components of the thimble clevis work together to create a secure and reliable connection between the conductor and the supporting structure. This ensures the integrity and functionality of the overhead transmission lines. A thimble clevis consists of the following components.

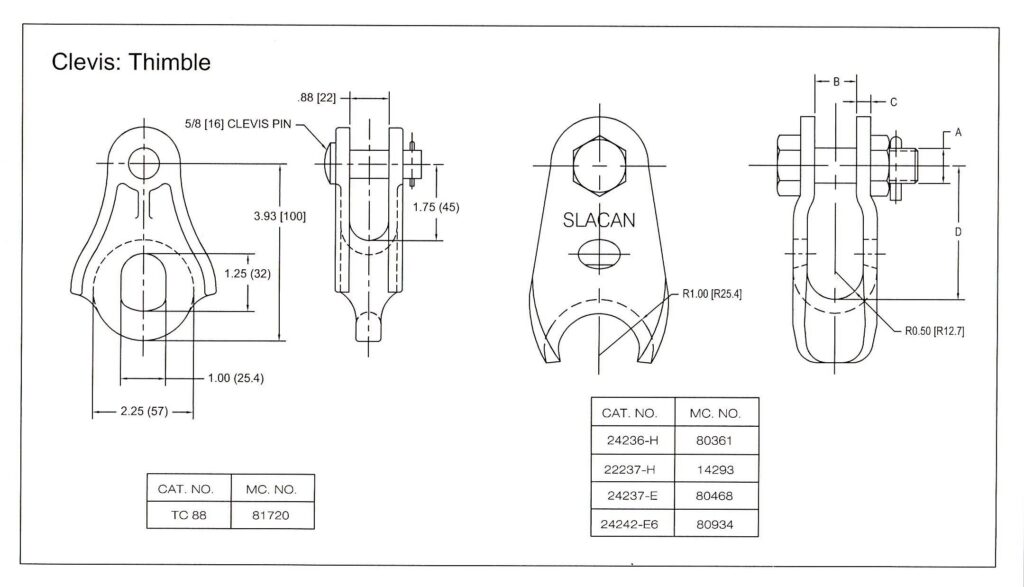

- Clevis – this is the u-shaped fitting that forms the main body of the thimble clevis. It is usually made of high-strength metal like steel or aluminum. It has holes or slots to accommodate fasteners which allow it to attach to the hardware or support structure.

- Thimble – the thimble is a cylindrical metal sleeve that fits inside the clevis. It provides a protective barrier and mechanical support for the conductor. It also prevents direct contact between the conductor and the clevis to reduce the risk of abrasion and damage.

- Fastener – thimble clevises secure to the hardware or support structure using bolts or other fasteners. They pass through the holes or slots in the clevis and secure it firmly in place.

- Cotter pin – a cotter pin works in secondary securing mechanism that inserts through a hole in the bolt or fastener. This is to prevent it from loosening or coming undone unintentionally.

- Coating – they have a protective coating like galvanization or specialized corrosion-resistant finish. They help enhance the durability and resistance to environmental factors.

Types of thimble clevis used on the transmission lines

There are various types of thimble clevis used on overhead transmission lines. Each type help to meet specific applications and requirements. Choosing the thimble clevises depends on various factors such as conductor size, mechanical load requirements, environmental conditions and specific project specifications. Discussed below are the types of thimble clevis used on the transmission lines.

- Heavy-duty thimble clevises – these can withstand higher mechanical loads and offer increased strength and durability. They work in areas where the conductor is prone to significant tension or where extra load-carrying capacity is necessary.

- Standard thimble clevises – this is the most basic and widely used type of thimble clevises. It consists of a U-shaped clevis and a cylindrical thimble that fits inside. They work in general purpose applications and provide reliable support for conductors.

- Insulated thimble clevises – insulated thimble clevises have an insulating material like polymer or composite integrated into the thimble. They provide electrical insulation between the conductor and the hardware. This is to minimize the risk of electrical leakage.

- Adjustable thimble clevises – these clevises have extra features that allows for adjusting tension of the conductor. They have a threaded part or mechanism for fine tuning the position of the thimble within the clevis. This enables easy tension adjustment during installation or for future line maintenance.

- Ball and socket – ball and socket feature a ball joint connection between the clevis and the thimble. This allows for some angular movement and flexibility. This allows for slight misalignment between the conductor and the supporting hardware.

Application of the thimble clevises

Thimble clevis is a vital component in the construction, operation and maintenance of the transmission lines. Its application ensures the safe and reliable transmission of electric power. It also distributes loads and maintains the necessary tension levels. Thimble clevises works in overhead transmission lines for the following applications.

- Conductor attachment – thimble clevises attach the conductor to the other hardware components in the systems. They provide reliable and sound connection ensuring the conductor remains securely in place.

- Adjustability – thimble clevis allow for easy tension adjustment during installation or maintenance. They help achieve and maintain the desired tension levels and sag characteristics of the conductor.

- Conductor suspension – the devices suspend or support the conductors in overhead transmission lines. They also provide a secure connection between the conductor and the supporting structure like poles and towers.

- Insulation and protection – thimble clevises distribute the mechanical loads and stresses along the length of the conductor. They act as a barrier between the conductor and the metal clevis reducing the risk of abrasion, wear and damage to the conductor’s insulation.

- Tensioning system – they play a vital role in the tensioning system of overhead transmission lines. they provide a secure connection between the conductor and the supporting structure.

- Load distribution – they distribute the mechanical loads and stresses along the length of the conductor. They also distribute the weight and tension on the lines to prevent stress concentration points. This minimizes the risk of conductor failure or damage.

Installation of the thimble clevis on transmission lines

The installation process of the thimble clevises depends on the design of the clevis and transmission structure. Also, it is advisable to follow the guidelines and instructions provided for the specific thimble clevis. The installation of the thimble clevis involves several steps discussed below.

- Ensure that you have the necessary equipment, tools and safety gear. Review the project specifications and instructions provided by the manufacturer.

- Identify the suitable location on the transmission line to install the clevis. Ensure it aligns with the desired path of the conductor.

- Remove any existing hardware or insulation covers that may obstruct the installation of the thimble clevis. This ensure tat the conductor is clean and free from any contaminants.

- Place the thimble inside the clevis to ensure it is securely positioned. Align the holes or slots in the clevis with the attachment points on the transmission line structure.

- Tighten the bolts or fasteners using the appropriate tools like wrenches or socket sets. Follow the recommended torque settings provided by the manufacturer or utility company. This helps to ensure proper fastening without over-tightening or damaging the components.

- Inspect the installation to ensure the thimble clevises aligns and attaches properly. This is to ensure they are free from any visible defects or abnormalities. Check that the conductor positions correctly within the thimble. Ensure there is sufficient clearance and no signs of strain.

- Install any insulation covers or protective sleeves on the thimble or conductor. This is to provide additional electrical insulation and protection against environmental factors.

- Verify that the installation meets the required standards and specifications. This involves inspections, measurements or tests. This is to ensure the integrity and functionality of the thimble clevises and transmission line systems.

Choosing the best thimble clevis

There are different types and designs of the thimble clevis used for transmission lines. They are also from different manufacturers with different specifications for transmission lines. it is important to consider several factors to ensure compatibility, reliability and performance. Choose the best thimble clevises that meets the specific requirements of your transmission line. This is to ensure reliability and longevity. The following are the main factors to consider when selecting the thimble clevis.

- Check the conductor size and type to ensure compatibility on the transmission lines.

- Evaluate the mechanical load requirements of the transmission line like tension, weight and environmental conditions.

- Consider the material and coating of the clevis like steel and aluminum. They should have the properties to resist rust and corrosion for longevity.

- Assess the design features of the thimble clevises like adjustability for tensioning or accommodating angular movement.

- The thimble clevis should be compatible with other hardware components in the system. This includes suspension insulators, yoke plates or pole fittings.

- Check the reputation and track record of the manufacturer or supplier.

- The thimble clevises should comply with industry standards and certifications. It should adhere to the recognized standards that help ensure the quality, safety and reliability of the thimble clevises.

- Consider the specific requirements provided by the utility company or project engineers.