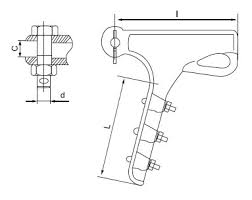

A tension clamp is a device used to securely anchor and support conductors used on transmission lines. It helps to maintain the proper tension and alignment of the conductors. Tension clamp also allows for adjustment of tension of conductor cables. This also helps to prevent sagging which leads to ground clearance violations. Tension clamps help to ensure the safe and reliable distribution of electrical power. They are from materials that offer strength, durability and resistance to environmental factors. These materials help them to withstand the tropical storms and extreme weather conditions in South American countries. Types of the clamps include bolted tension clamps, compression tension clamp, wedge clamps and suspension clamps. They find use in applications such as transmission lines, telecommunications, railway electrification and agricultural fencing.

Key features of tension clamp

Tension clamps have various features that help to tension cables, wires, conductors and other load-bearing elements. These features help to ensure the reliability and safety of the systems they work in. The following are the key features of the tension clamps.

- Corrosion resistance – tension clamps have coatings and materials that resist corrosion. This makes it suitable for outdoor and exposed applications.

- Gripping mechanisms – they have gripping mechanisms such as wedges, bolts, compression or clamps. They help to securely hold the cable or conductors in place.

- Load-bearing capacity – tension clamps are capable of withstanding specific load or forces. The capacity should match the requirements of the application.

- Ease of installation – the clamps have features that help reduce installation time and maintenance.

- Compatibility – the clamps should be compatible with the type and size of the cable, conductor and load bearing elements. This helps to ensure a secure and reliable connection.

- Durability – tension clamps are capable to withstand the test of time. It also helps maintain their functionality over many years of service.

- Material – the clamps are from materials that offer strength, durability and resistance. These materials include steel, aluminum, stainless steel or composite materials.

- Vibration damping – they may have features for vibration dampening. Vibration could lead to damage, fatigue or interference.

- Temperature resistance – the clamps are capable of withstanding temperature variations without compromising performance.

Selection and installation of tension clamp

The selected tension clamps should ensure the reliability and safety of the application. It includes considering several factors that influence the decision-making process. These factors include type of application, conductor type, environmental conditions, adjustability, gripping mechanism and costs. The installation should help to secure and tension cables, conductors or load-bearing elements. The following is the general installation process of the tension clamps.

- Safety precautions – follow all the safety guidelines and wear appropriate personal protective equipment.

- Pre-inspection – inspect the tension clamps to ensure they are in good condition and free from defects.

- Support structure preparation – ensure the support structure is stable and all the anchors are in place.

- Positioning – place the tension clamps at the desired locations along the conductor, cable or load-bearing element. Ensure proper spacing and alignment according to the requirements.

- Attach the tension clamps – use the suitable mechanisms to attach them to the cable or conductor. Common mechanisms include bolting, compressing, wedging or clamping.

- Tightening – tighten or adjust the clamps to achieve the desired tension in the cable or conductor. This is mainly done using a torque wrench or other tools to ensure secure clamps.

- Safety locking – engage the locking mechanisms to prevent accidental disengagement.

- Insulation – ensure the clamps have insulations to prevent electrical interferences if applicable.

- Vibration damping – install the vibration damping components on vibration-prone conductors.

- Load tests – perform load tests to ensure the tension clamps can withstand the expected loads and tensions.

- Documentation – maintain detailed records of the installation process. This includes the type and location of tension clamps, torque settings and other adjustments.

Maintenance and inspection of tension clamps

Proper maintenance and inspection help to ensure the continued reliability of the application. The frequency of maintenance and inspection depends on the environmental conditions. This also helps to identify issues early and prevent potential problems and ensure proper tension in cables. The following is a basic guide for maintenance and inspection of the tension clamps.

- Conduct routine visual inspections of tension clamps at scheduled intervals. This ranges from monthly to annually depending on the application.

- Check for signs of physical damage, corrosion, wear, loose fasteners and proper alignment.

- Use suitable tension-measuring tools to ensure the desired tension is within acceptable range.

- Perform load tests to verify that the tension clamps can still support the expected loads.

- Ensure the insulation remains intact and effective at preventing electrical interference.

- Ensure the insulation remains intact and effective at preventing electrical interference.

- Clean the tension clamps to remove dirt, dust or debris that could hinder their functionality.

- Apply lubricants to moving parts or components such as bolts, wedges to ensure smooth operation.

- Check the exposure to the corrosive environments and apply anti-corrosion coatings or treatments.

- Inspect and maintain any vibration-damping components or devices. This is to ensure they are functioning correctly.

Comparative analysis of tension clamps in South America

A comparative analysis includes evaluating and assessing different types and brands. It also includes evaluating different manufacturers and suppliers of tension clamps. It helps to ensure proper selection of the clamps for the different applications in South America. Additionally, it is advisable to consult with industry experts for guidance on the selection process. The following are the factors to include in the comparative analysis in South America.

- Types of tension clamps – there are various types and designs of tension clamps in the market. These types find use in various applications such as overhead power lines, telecommunications and construction.

- Materials – the tension clamps should have materials and their resistance to corrosion. Common materials include steel, aluminum and composite materials.

- Infrastructure development – expansion of electrical grids and telecommunication networks influence the supply of tension clamps.

- Renewable energy – examine the role of tension clamps in renewable energy projects such as solar and wind farms.

- Maintenance and inspection – compare the different maintenance and inspection practices for tension clamps. Examine the frequency of maintenance and the use of vibration damping mechanisms.

- Environmental conditions – evaluate the different climates and geographies in the South American region. Assess how the tension clamps perform in the different environmental conditions.

- Electrical and telecommunication networks – examine the role of tension clamps in the expansion of electrical grids.

Certifications and standards in South America

There are various certifications and standards that regulate the use of tension clamps in South America. They help to ensure their quality, safety and compliance with industry practices. Each country has their own set f local and national standards for use of tension clamps. Additionally, it is advisable to consult with local regulatory authorities. This is to ensure they meet all the requirements. The following are the certifications and standards for tension clamps in South America.

- IEC standards – these are international standards of electrical and electronic equipment.

- ISO certifications – this ensures the clamps meet the quality standards.

- ASTM international – this provides a range of standards for various industries related to materials, manufacturing processes and safety.

- IEEE standards – these are standards for the electrical and electronic industries related to power systems.

- Local and national standards – these are standards that vary by country related to electrical and construction materials.

- Telecommunication standards – tension clamps should meet industry specific standards. This varies depending on the technology used and type of cables.

- Environmental standards – the clamps should comply with environmental standards to minimize their impact in the environment.

Regional market for tension clamp in South America

There are various market trends that influence the regional market for tension clamps in South America. These factors include manufacturers, brands and types of tension clamps. Additionally, it is advisable to consult with industry experts for guidelines on how to assess the factors. Also, manufacturers and suppliers should assess these dynamics to ensure their continued success. The following are the factors that shape the market for tension clamp market.

- Market trends – gather information about market trends, technological advancements and innovations in tension clamps.

- Competition – availability of local and international manufacturers impact competition and pricing in the market.

- Renewable energy trends – the growing adoption of renewable energy sources require use of tension clamps.

- Environmental conditions – there is diverse environmental conditions in south America. These include humidity, temperature variations and coastal areas.

- Telecommunication industry – tension clamps help to secure and support communication lines in these networks.

- Economic factors – economic growth and stability leads to increased infrastructure investments. This in turn helps to boost the market for tension clamps.