A spool tie is a component used to secure and support conductors on the overhead transmission lines. Spool ties help to maintain the proper spacing and alignment of the conductors and minimize vibrations. The spool tie consists of material bracket or clamp that attaches to the structure. The spool-shaped design allows the conductor to pass through it and secure n place.It tightens or adjusts using the necessary equipment to ensure the conductor is properly supported and maintained in its position. Spool ties are usually used to maintain the structural integrity and reliable operation of overhead transmission lines. this helps prevent movement and ensure proper alignment of the conductors.

Components of spool tie

There are different and specific designs of the spool ties which may consists of different components and features. The components of the spool tie also vary depending on the manufacturer, intended use and requirements of the transmission lines. the following are the general components of the spool ties.

- Spool – this is the central component of the spool tie which is cylindrical designed to allow the conductor to pass through it and be able secured in place. This is the component that provides support and helps maintain the proper alignment of the conductor.

- Bracket – this is the component where the spool attaches to secure to the structure. It holds the spool in place and provides the anchoring support for the spool tie.

- Fasteners – spool ties work with fasteners such as bolts, nuts and screws to secure the bracket to the structure. This helps the spool ties to remain firmly attached and can withstand the tension and forces applied to it.

- Tensioning mechanism – spool ties include a tensioning mechanism that adjusts the tension of the conductor. The mechanism is a threaded rod, turnbuckle or similar device. This allows for tightening or loosening the spool tie to achieve the desired tension.

Types of spool ties

Types of spool ties used on the overhead transmission lines depend on the specific application and requirements. They also depend on the region, regulations and specific requirements of the transmission lines. the common types of spool ties are as discussed below.

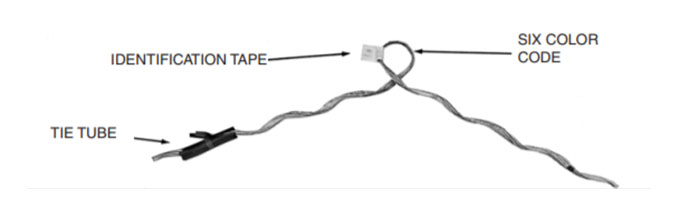

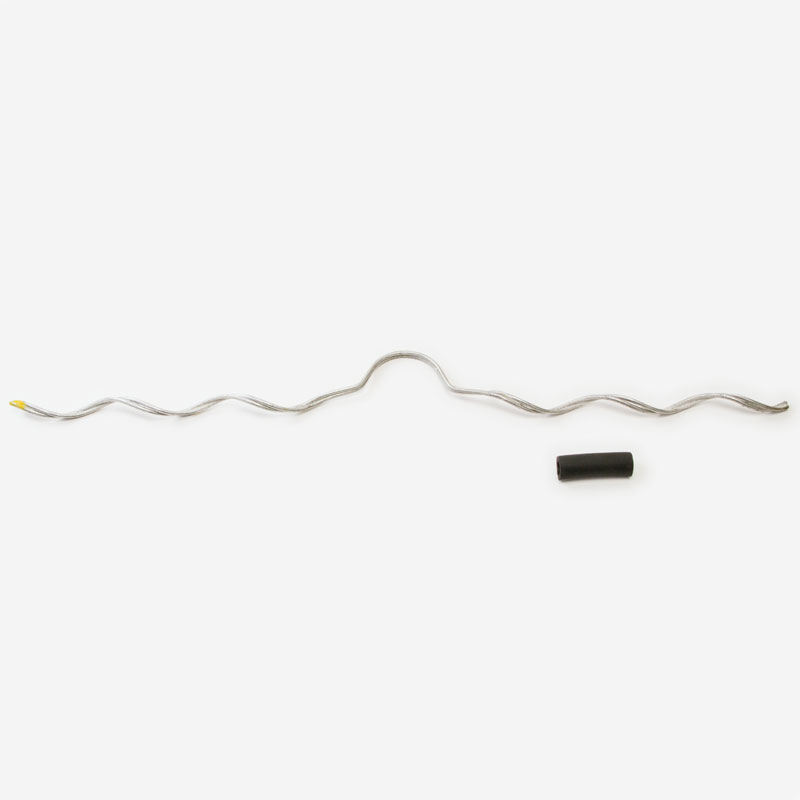

- Preformed spool ties – preformed spool ties are from a preformed wire or rod shaped into a spool-like configuration. This type provides flexibility and ease of installation since they easily wrap around the conductor and secured to the bracket.

- Bolted spool ties – these spool ties consist of a spool attached to the bracket using bolts to provide the structure with the help of fasteners like nuts and washers. They allow for easy installation and adjustment on the overhead transmission lines.

- Tensioning spool ties -these spool ties incorporate the tensioning mechanism to allow for adjusting the tension of the conductor. They include features like threaded rods, turnbuckles or other devices that facilitate tension adjustment.

- Welded spool ties -the spool weld directly to the bracket to eliminate the need for bolts or fasteners. They provide a strong and permanent connection but challenging to adjust or replace.

- Composite spool ties – spool ties are from composite materials which provides high strength-to-weight ratio, corrosion resistance and electrical insulation properties. They work in areas where conductivity and interference need to reduce.

Applications of spool ties

Spool insulators ensure the stability, functionality and longevity of overhead transmission lines. this is by providing support, tension and control over conductor alignment. The following are the common applications of spool ties.

- Vibration damping – spool ties reduce the vibrations and oscillations of conductors caused by wind or other factors. They minimize the movement of conductors and dampen vibrations. They improve the reliability and lifespan of the transmission line.

- Conductor support – the main function of the spool ties is to provide support and secure conductors in overhead transmission lines.

- Line maintenance and repair – the ties facilitate easier maintenance and repair activities on overhead transmission lines. This allows for the controlled release and tensioning of conductors. This enables workers to access and work on specific sections of the line.

- Line tensioning – spool ties with tensioning mechanisms allow for adjusting the tension of the conductors. It is useful when dealing with long spans.

- Electrical insulation – spool ties help minimize electrical interference. This is to ensure proper insulation between the conductors and the supporting structure.

Installation process of spool ties

The installation process of the spool ties varies depending on the specific design of the spool tie and the manufacturer’s instructions. Most of the manufacturers in the market provide procedures for the installation of the devices. The following is a basic process of the installation process.

- Prepare the area to install the spool tie by inspecting the structure and identifying the appropriate location for the spool tie.

- Secure the bracket to the structure using bolts, nuts, or screws. The bracket should be firmly attached and aligned properly to ensure stability and support.

- Thread the conductor by passing the conductor through the central opening of the spool.

- Secure the conductor by tightening the spool tie and ensuring it holds the conductor firmly.

- Adjust the tension if applicable by utilizing the tensioning mechanisms to achieve the desired tension.

- Repeat this for extra spool ties and ensure proper spacing and alignment between them.

- Conduct inspection to verify that the conductors are properly secured and aligned. Test the tensioning mechanisms to ensure they are properly functioning.

Selecting the best spool tie

There are various types and designs of spool ties out in the market that may make the decision-making process a little difficult. Choosing the best spool tie depends on various factors like the requirements of the project, environmental conditions and regulatory standards. It is advisable to consult with industry professionals or engineers experienced in overhead transmission lines construction. They can provide guidelines on the best spool tie to use for your project. The following are the key factors to consider during the selection.

- Determine the load capacity of the spool insulator based on the anticipated load on the conductor. The spool tie should be capable of supporting the weight of the conductor and withstand external forces.

- Consider the material used in the manufacture of the spool ties. This includes steel, aluminum, fiberglass or composite materials. The materials provide strength, durability, electrical conductivity and resistance to corrosion.

- Evaluate the electrical properties of the spool tie to check if the electrical insulation is necessary.

- Consider the environmental conditions where the spool tie will install. Consider factors like temperature extremes, exposure to UV light, moisture and chemical exposure.

- Evaluate the ease of installation and maintenance requirements beforehand. The selected spool tie should have features that facilitate quick and efficient installation available spare parts for maintenance.

- Ensure that that the spool tie meets the relevant regulatory standards and industry requirements.

- Consider the reputation and track record of the manufacturer. They should have a track record for producing high-quality spool ties. They should also provide reliable customer support.