A corona ring is a specialized component used in high voltage electrical systems to control corona discharge. Corona discharge occurs when there is a high electric field gradient around conductors. This leads to the ionization of the surrounding air and the formation of a visible glow. Corona discharge can result in power loss, electromagnetic interference and damage to equipment. Corona rings install around high voltage components such as insulators, connectors or bushings. It helps to distribute the electric field gradient more evenly. This reduces the intensity of the electric field at critical points. It also helps in suppressing the formation of corona discharge. Corona rings are from durable and materials with high strength like copper and aluminum. Corona rings help improve the efficiency, reliability and safety of high voltage systems.

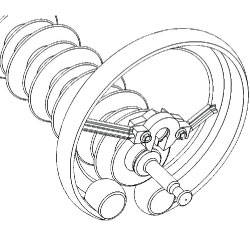

Components of the corona ring

Corona rings has various components that work together to create a corona control system. This system in turn helps manage the electric field. The components reduce the effects of corona discharge in overhead transmission lines. The following are the main components of the corona ring.

- Ring structure – these are the core components of the corona ring. The ring positions around high-voltage conductors. The conductive materials help to control the electric field. It is from materials such as aluminum, copper or other alloys.

- Insulators – these help to separate the corona ring from the supporting structure. This is to prevent electrical current from flowing between them.

- Spacing elements – these elements help to maintain a specific distance between the ring and the conductor. This is to ensure the effectiveness of the corona control by distributing the electric field.

- Surface finish – corona rings undergo treatments to enhance their performance and conversion coating. This provides protection against corrosion, improve electrical properties and increase resistance to environmental factors.

- Support structure – the ring attaches to the support structure to keep them at a specific distance.

- Mounting hardware – these include nut, bolts, flanges, holes, clamps and washers used to secure the corona rings.

Applications of corona ring

Corona rings have a variety of applications in the high-voltage transmission industry. They help to manage and control corona discharge on transmission lines. They also contribute to the integrity and performance of high-voltage systems. This is by reducing corona discharge and associated difficulties. The corona ring’s most prevalent applications include the following.

- Overhead transmission lines – corona rings install on high voltage transmission lines to control corona discharge. They help reduce energy loss, audible noise, radio interference and potential equipment damage.

- Converter stations – corona rings help control corona discharge on converter transformers, bushings and other high-voltage components. This is by distributing the electric field gradient to prevent insulation breakdown. It also helps to extend the lifespan of transformer components for optimal performance.

- High-voltage testing – the rings also help prevent unwanted corona discharge on the systems. This could interfere with the accurate testing results. This is by simulating corona discharge conditions to enable researchers to study the effects of high voltage on materials and systems.

- Lightning arrestors – corona rings are part of the design of lightning arrestors assisting in the prevention of corona discharge.

- Switchyards – the rings manage corona discharge on several equipment. This is including circuit breakers, disconnectors and other high-voltage devices.

- Wind energy – the rings manage corona effects on high-voltage components in wind turbines and generators. They enhance the reliability of the electrical infrastructure.

Selecting the best corona ring

When choosing the ideal corona ring, you must consider some aspects to ensure that it is appropriate for your particular purpose. The rings’ selection will be depending on the voltage levels, environmental circumstances, and planned applications. The selected corona ring should ensure the transmission lines’ safety, dependability, and efficacy. The following are some frequent things to consider while choosing corona rings.

- Voltage level – select a corona ring that can handle the voltage level of your transmission or distribution system.

- Application requirements – consider the type of application intended for the corona ring. Different designs work in overhead transmission lines, substations, switchyards and other applications.

- Installation ease – consider the ease of installation and whether the corona rings come with the necessary mounting hardware and instructions.

- Design – check the design and geometry of the corona ring to ensure compatibility with the installation location. Consider factors such as ring shape, dimensions, mounting provisions and alignment requirements.

- Cost effectiveness – consider the budget available for the corona rings. Find a balance between quality and cost effectiveness.

- Material compatibility – consider the material used to make the ring like copper or aluminum. Select one that offers good, corrosion resistance and mechanical strength and electrical conductivity.

- Surface treatments – consider any surface treatments applied to the corona ring. This is to enhance its performance and durability. Common treatments include anodizing, plating, coating or passivation.

- Supplier – choose corona rings from reputable manufacturers known for producing high-quality products and reliable products.

- Compliance with standards – ensure the selected corona rings follow relevant industry standards and regulations.

- Performance testing – consider conducting performance testing to assess the effectiveness of the selected corona ring.

- Environmental factors – consider the environmental conditions the corona ring will deal with. These includes pollution, UV exposure and temperature.

Installation process of corona rings

Corona ring installation takes many steps to ensure appropriate positioning and successful corona control. Additionally, follow the manufacturer’s instructions to ensure the corona control system works . This improves the efficiency and dependability of the high-voltage system. The fundamental installation technique for the corona ring is as follows.

- Gather all the necessary tools, equipment and materials required. Ensure the components are clean and free of any debris, contaminants or damage.

- Follow all the safety protocols such as wearing suitable personal protective equipment. This helps to ensure safety in the work environment.

- Identify the locations on the transmission line, substation equipment or other components. The ring should position encircle the component to allow for even distribution of the electrical field gradient.

- Clean the installation area to remove dirt, dust, grease and other contaminants that could affect adhesion.

- Attach the corona ring to the high voltage component using the provided mounting provisions. This may involve fastening the corona ring with bolts, screws, clamps or other hardware.

- Maintain the recommended spacing and alignment between the corona ring and the conductor. Ensure the uniform alignment of the corona rings along the length of the installation. Proper alignment helps to optimize the performance of the corona ring in controlling corona discharge.

- Conduct a thorough visual inspection of the installed corona rings to ensure they align and attach. Check for signs of damage, misalignment or loose fasteners that may affect the effectiveness of the ring.

- Test the installations to verify the effectiveness of the corona control system. This involves conducting partial discharge tests, insulation resistance measurements and other diagnostic procedures. This is to ensure proper operation of the high voltage system.

- Document the installation process including location, date, inspection finding and any relevant observations. This helps to ensure traceability and ease maintenance and future inspections.

Maintenance practices for corona rings

Corona rings are regularly maintained to guarantee effective control of corona discharge in high-voltage electrical systems. It also aids in identifying any faults or wear that may impair their performance. A variety of factors influence the regularity with which maintenance and inspection take place. These include the operating environment, the importance of the application, and manufacturer guidelines. The following is a simple maintenance and inspection instructions for corona rings.

- Inspection – conduct routine visual inspections of the corona rings. Check for signs of physical damage, corrosion or contamination. It ensures they are securely attached and aligned with the components meant to protect.

- Cleaning – clean the corona rings using a non-abrasive cloth or mild cleaning solution if there are signs of dust, dirt or pollutants.

- Fasteners – check the tightness of the bolts, nuts, clamps or other fasteners used to secure the corona rings. Loose fasteners can compromise the effectiveness of the corona ring.

- Replacement – check the condition and performance of the rings over time. Consider replacing them if there is presence of damage.

- Surface treatment maintenance – perform any necessary touch-ups on the corona ring coatings. Proper surface treatment maintenance helps protect the corona ring against corrosion and environmental degradation.

- Testing – perform electrical tests to verify the integrity of the corona rings. This is by following the recommended testing procedures and frequency.

- Environmental conditions – consider the environmental conditions in which the corona rings install. This is including exposure to UV radiation, extreme temperatures and pollution.

- Documentation – keep detailed records of maintenance and inspection activities. This is including dates, findings and any corrective actions taken.

Frequently asked questions

Corona rings work by distributing the electric field gradient around high voltage components like insulators. This helps prevent the concentration of electrical stress that leads to corona discharge. They also help mitigate corona discharge and maintain system integrity.

The benefits of using corona rings include the reduction of corona discharge and extended equipment lifespan. They also include improved system performance, enhanced safety and visual sign of high voltage.