On transmission lines, a spiral vibration damper is a device that lessens aeolian vibration caused by strong winds. Another name for the dampers is Stockbridge dampers. Throughout the length of the line, the dampers install sparingly. It consists of up of a metal structure that encircles the conductor in a spiral pattern. This form lessens stress on the conductor and aids in dissipating the energy of vibrations caused by the wind. On transmission lines, spiral vibration dampers function to increase the lines’ durability. The lines and support structures may experience wear and tear due to a variety of environmental variables. Applications that lower damage risks use spiral vibration dampers.

Spiral vibration damper functions

There are several uses for spiral vibration dampers on overhead transmission lines. The primary goals are to improve system reliability, stop galloping and lessen vibrations. Spiral vibration dampers in overhead transmission lines serve the following purposes.

Minimize vibrations – dampers lessen the vibration’s amplitude in transmission cables overhead. The wind sweeping over the lines is what causes the vibrations, which over time may cause weariness and failure. Additionally, the damper lessens the effect on the line by absorbing and dispersing some of the energy.

Boost system dependability — spiral vibration dampers help make installations more dependable. Additionally, by lessening the strain on the conductors, they contribute to the lifespan extension of overhead transmission lines.

Stop galloping – when there are vibrations caused by the wind, the dampers aid in preventing galloping. Galloping can cause damage by putting stress on the line and its supporting supports. This contributes to keeping the line stable as well.

Boost safety – vibrations can put the public and employees who work close to the wires at risk for injury. By keeping the lines stable and lowering the possibility of breakdowns, the dampers assist in lowering the risks.

Prolonged lifespan – the dampers lessen the strain on transmission line parts. This lessens the need for regular maintenance and repairs and increases the equipment’s lifespan.

Spiral vibration damper designs

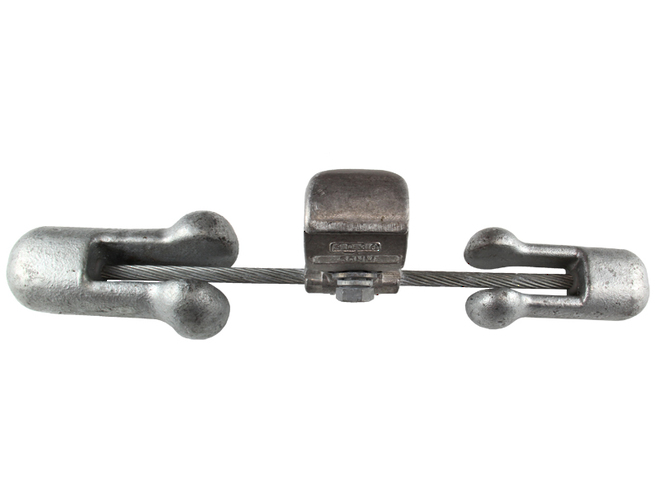

Overhead transmission cables are less vibrational thanks to the spiral vibration damper’s design. Also, the designs offer adaptability, flexibility and durability to support various working environments. The different spiral vibration damper design components are as follows.

Spiral structure – the damper’s construction consists of a spiral pattern that permits vibration absorption.

Attachment points – throughout its length, the damper connects to the transmission line conductor at many locations. They also aid in keeping the damper in position and in reducing vibrations in the line.

Ruggedness – the dampers become resistant to the demands of outdoor use and exposure to inclement weather. This contributes to durability, which guarantees sustained performance in challenging settings.

Material – the dampers are from sturdy, long-lasting materials such composites, steel and aluminum. They offer the damping qualities and the resilience to withstand environmental conditions.

Flexibility – dampers’ flexible structure enables them to absorb and disperse the energy produced by vibrations caused by the wind. This occurs without subjecting the transmission line conductor to excessive stress.

Adjustability – to accommodate various transmission line designs, the dampers may include adjustable characteristics. This enables the damping properties to be optimally tuned to meet the particular requirements.

Use cases for Stockbridge dampers

Beyond power lines, spiral vibration dampers serve in infrastructure projects. It’s also a good idea to manage and reduce wind-induced vibrations. They also extend the lifespan, safety and dependability of different systems and buildings. The different uses of spiral vibration dampers are as covered here.

Fiber optic cables – in fiber optic cable installations, the dampers function to guard against damage to the cables. Additionally, they support dependable communication across a range of applications.

Towers and masts – these work in broadcasting applications and vibrate due to wind loads.

High-voltage power lines – these lines require maintenance for the clamps to function properly. In high-voltage lines, the dampers aid in preventing galloping and other dynamic instabilities.

Transmission and distribution lines – dampers function in distribution and transmission lines to reduce vibrations caused by wind. They guarantee continuous power transfer and improve reliability.

Bridges – wind-induced vibrations affect the structural integrity and stability of suspension bridge dampers. By acting on the bridge cables, the dampers can lessen the likelihood of resonance and these vibrations.

Railway electrification – train movements can cause the catenary wires to vibrate. These catenary wires can have spiral vibration dampers installed along them to lessen wear and tear and vibrations. This is primarily to provide a steady supply of power.

Industrial structures – the dampers operate in tall buildings, cooling towers and chimneys. By doing this, they ensure the integrity and stability of the structures or industrial installations.

Cable stayed bridges – bridges with cable stays reduce vibrations by supporting the bridge deck with cables and towers. They also improve the bridge’s usability and safety.

Wind farms – tower vibrations caused by wind are a result of the dynamic loads that wind turbines experience. They improve the turbines’ structural integrity and performance.

How to gauge the spiral vibration damper’s tensile strength

There are several elements that affect the spiral vibration dampers’ tensile strength. These consist of the design, the material utilized and the particular application needs. To ensure their efficiency, they are also made with designs that can sustain severe tensile stresses. Tensile strength originates by applying a controlled tensile force to the damper until it breaks. For advice on the tensile strength, it is also advisable to speak with professionals. An overview of measuring a spiral vibration damper’s tensile strength is as provided below.

Make sure the damper is ready for testing and that it is in good working order. It entails clearing out any outside impurities and making sure the damper is securely fastened to a testing device.

Attach the damper to a testing apparatus so that force applies evenly and straight throughout its length.

Measure and note the damper’s original length and diameter at this point. The engineering stress and strain during the test is through the aid of the data.

Apply the tensile force to the damper until it breaks by utilizing the testing machine. Measure and record the damper’s elongation or deformation along with the applied force.

Using the recorded data, determine the damper’s tensile strength. Units of force per unit area help to express tensile strength. Keep track of the testing process, including the tools utilized, the force applied and the tensile strength.

Difficulties and problems with using a spiral vibration damper

There are various advantages of using spiral vibration dampers to lessen vibrations caused by wind. They also improve the structures’ stability. It is also advisable to address these issues to enhance the installation techniques, materials and design. The many difficulties and problems with using spiral vibration dampers are as listed below.

Installation and maintenance costs – specialized tools and knowledge are necessary for the damper installation process. The ampers’ ongoing efficacy remains guaranteed by routine maintenance and inspection.

Environmental factors – the dampers are subject to a range of environmental conditions. Extremes in humidity, temperature and UV radiation exposure are a few of them. The materials and functionality of the dampers deteriorate under these circumstances, lowering their lifespan’s effectiveness.

Performance and effectiveness – the dampers improve the application’s stability and lessen vibrations. This is depending upon variables such as the damper’s design and the size and frequency of vibrations caused by wind. The dampers support applications in achieving peak performance in a variety of operational environments.

Integration and compatibility – the dampers must work with the particular design and arrangement of the structures. To improve their performance, make sure that they are properly integrated and aligned with the current infrastructure.

Dynamic forces and loads – transmission lines experience stresses and dynamic loads from a variety of sources. These consist of mechanical impacts, ice formation and bird perching. It can be difficult to mitigate these dynamic loads, particularly in areas with severe weather.

Frequently asked questions

What is a spiral vibration damper?

In electrical installations, a spiral vibration damper is a tool used to improve stability and lessen vibrations caused by wind.

How does a spiral vibration damper work?

The energy produced by vibrations caused by wind becomes absorbed and dispersed by spiral vibration dampers. They lessen the load on the support structures and conductors as well as the vibrations’ amplitude.

What is the design of a spiral vibration damper?

The spiral vibration damper’s structure consists of sturdy materials and forms like a spiral. These consist of composites, steel and aluminum. Its design seeks to be adaptable, strong and vibration-dampening in a range of applications.

In electrical installations, what role do spiral vibration dampers play?

Spiral vibration dampers improve stability, stop galloping, lessen wind-induced vibrations and increase transmission line longevity. They provide dependable power transfer and enhance safety as well.

What are the challenges facing the use of spiral vibration dampers?

Spiral vibration dampers encounter some difficulties, including expenses associated with installation and upkeep, problems with compatibility and integration, environmental factors and guaranteeing greatest efficacy and performance.