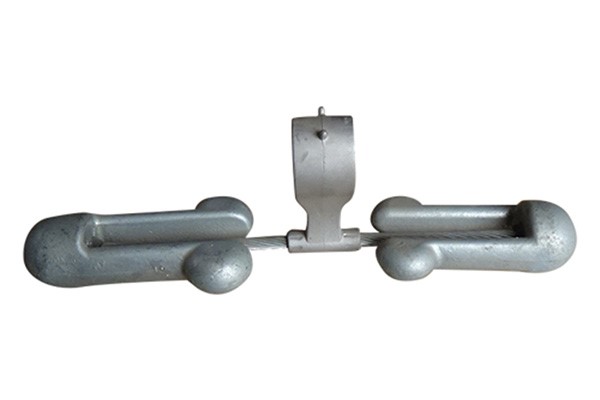

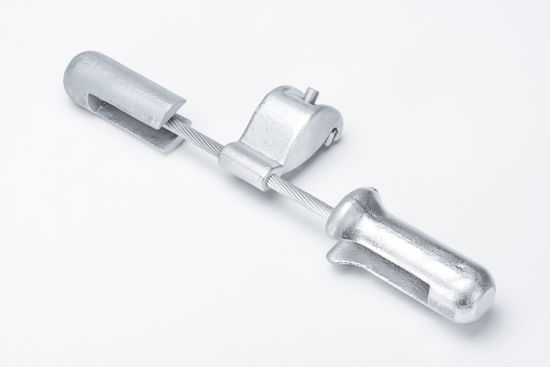

A spiral vibration damper is a device used to dampen vibrations in various overhead applications. It is also known as an SVD, helical vibration damper or Stockbridge dampers. It consists of a helical coil made of a material with high damping properties. The coils have designs to absorb and dissipate vibration energy. It then converts the energy into heat through internal friction within the material. The damping effectiveness of the spiral vibration damper depends on various factors. These include material properties, dimensions and installation configuration. Also, the spiral vibration dampers can deform from various environmental conditions. These include humidity, temperature and exposure to UV radiation. Helical vibration dampers are effective across a wide range of frequencies. This is including wind, mechanical oscillations and resonances.

Technical specifications for spiral vibration damper

Technical specifications for spiral vibration dampers vary depending on the manufacturer and application. the specifications help to select the suitable spiral vibration dampers for specific applications. It is also dependent on factors such as vibration amplitude, frequency and environmental factors. The following are the common technical specifications for spiral vibration dampers.

| Catalog Number | Diameter range (Min) | Diameter range (Max) | Units per carton | Wt./Lbs | Length (inches) | Color code |

| 5050102 | 174 | 249 | 50 | 29 | 46 | Blue |

| 5050103 | 250 | 326 | 50 | 31 | 49 | Red |

| 5050104 | 327 | 461 | 50 | 34 | 51 | White |

| 5050105 | 462 | 563 | 50 | 36 | 53 | Orange |

| 5050106 | 564 | 760 | 25 | 50 | 65 | Yelllow |

- Material – the dampers are from materials like composite materials with high dampening properties. They help to absorb the vibration energy.

- Damping ratio – the damping ratio defines the effectiveness of the damper in dissipating vibration energy.

- Load capacity – this is the greatest load the damper can withstand without failure. This is important for applications with heavy loads or high winds.

- Testing and certification – this include documentation of testing procedures, performance characteristics and certification. This helps to verify compliance with specified technical standards. They also help ensure product quality and reliability.

- Dimensions – this is specifications about the diameter, length and pitch of the spiral coils. They should have designs to meet specific application requirements.

- Frequency range – this is the operation frequency range where the damper is effective in reducing vibrations.

- Operating temperature range – this is the temperature within which the damper can operate.

- Environmental resistance – this is resistance to various environmental factors. They include UV radiation, temperature variations, moisture and chemical exposure.

How to select supplier or vendor for spiral vibration damper

Finding the right supplier requires careful considerations to ensure you receive high-quality products. They should help to meet the technical specifications, delivery requirements and budget. Finding the right information about the suppliers helps to select a reliable supplier for SVDs. The following are the guides to help select a suitable supplier or vendor.

- Define your requirements – define your technical specifications for the supplier. This is including material, requirements, dimensions and load capacity.

- Research – conduct research to identify potential suppliers of spiral vibration dampers. Check on online directories, industry associations, trade shows and recommendations from experts.

- Review proposals and pricing – check the proposals received from suppliers considering various aspects. These include pricing, lead times, payment terms and any extra services offered.

- Supplier references – request references from the supplier for guidance. Also, contact other customers to gather feedback on their experience.

- Visit supplier conveniences – visit the nearest supplier stores in your area. This is to inspect their manufacturing processes, quality control measures and discuss the requirements in detail.

- Check supplier capabilities – assess each potential suppliers capabilities. This is including their experience, expertise, manufacturing capabilities and certifications.

- Review pricing – check the proposals received from suppliers. Consider pricing, lead times, payment terms and warranty terms.

- Quality assurance and certifications – ask about the supplier’s quality assurance processes, testing procedures and certifications. This is to ensure that the SVD meet industry standards and requirements for performance.

- Supplier selection – select the supplier that best suits your requirements. The supplier should also offer competitive value. This is depending on evaluation of proposals, supplier capabilities and quality assurance.

Cost comparisons for helical vibration dampers

Prices for spiral vibration dampers varies depending on suppliers, material and sizes. Other factors influencing costs for spiral vibration dampers include installation and long-term savings. Finding the accurate pricing depends on cable size and type, quantity required and material preference. Additionally, it is advisable to select a supplier that offers quality and affordability. The following are the factors related to cost to consider when comparing costs.

- Initial cost – compare the initial price of spiral vibration dampers from different suppliers. Ask for price lists from many vendors to assess the cost of acquiring the dampers.

- Shipping and handling fee – consider shipping and handling fees related with purchasing the SVDs. Compare the shipping costs and delivery times to check the total cost of procurement.

- Total cost of ownership – consider the total cost of ownership which includes the initial price. It also includes other factors such include maintenance, repair and replacement costs.

- Volume discounts – some of the suppliers offer discounted price for larger quantities of SVDs

- Payment terms – check the payment terms offered by the available suppliers. This is for options such as discounts or extended payment terms.

- Warranty and support – as about the warranty coverage and after-sales support provided by the supplier. A suitable vendor should provide help with installation, troubleshooting and maintenance.

- Supplier reputation – look for reviews, testimonials or references from other customers. This helps to gauge the reliability and responsiveness.

Community forums and interactions

Engaging in community forums and interactions related to SVD helps to gather valuable resources. The resources helps in information exchange and networking. It also helps to gain insights, share experiences and learn from professionals and experts. Additionally, it helps to enhance your knowledge and understanding of spiral vibration dampers. The following are ways to engage in spiral vibration dampers communities.

- Online platforms and discussion boards – join online forums and boards related to engineering, mechanical systems or specific industries. These include websites like Reddit, Eng-Tips and Engineering.com.

- LinkedIn groups – join communities focused on mechanical engineering, structural engineering or specific industries. These include aerospace, automotive, and power transmission.

- Online Q&A – these platforms have questions and discussions related to engineering topics. The topics include vibration control methods for spiral vibration dampers. These include platforms such as Quora or Engineering Stack Exchange.

- Research publications and conferences – explore academic journals, conference proceedings and technical publications. These relate to mechanical engineering, structural dynamics and vibration analysis.

- Professional associations – explore professional associations and societies relevant to your field of interest. These include ASME, IEEE or the international society for structural health monitoring of intelligent infrastructure.

- Industry-specific forums – check for communities where professionals discuss topics related to vibration control. These include communities like Utility Products Forums or Transmissions & Distribution world communities.

- Webinars and workshops – attend webinars, workshops or online events hosted by industry manufacturers. These events cover topics related to vibration control technologies. This is including selection, application and performance of the dampers.

Factors influencing material selection for helical vibration dampers

Spiral vibration dampers are from various materials that offer high strength and durability. The selection for the materials involves considering various factors to ensure optimal performance. Proper selection of the materials helps to meet the specific requirements of the applications. Additionally, it is advisable to consult with industry experts for guidance on the best materials for your needs. The following are the factors that influence the materials selection for the dampers.

- Damping properties – the selected materials should have high damping properties. They help to absorb and dissipate vibration energy.

- Fatigue resistance – the material should exhibit good fatigue resistance. Resistance helps to withstand repeated stress cycles without failure.

- Chemical resistance – select a material with good chemical resistance to ensure long-term durability. The dampers may face exposure to chemicals or environmental factors that can degrade the material.

- Weight considerations – select a material that provides the required damping performance. This is while reducing the weight of the vibration damper.

- Environmental impact – assess the environmental impact of the selected material. This is including factors such as recyclability, energy consumption and potential emissions.

- Mechanical properties – the selected material should have properties like strength, stiffness and resilience. This helps the dampers to withstand the operational loads and environmental conditions.

- Temperature stability – the material should maintain its damping properties and structural integrity. It should do this over the expected temperature variations.

Frequently asked questions

A spiral vibration damper is a device used to mitigate vibrations in overhead transmission structures. It consists of a helical coil made of materials with high damping properties. The damper absorbs vibrational energy by converting it into heat through internal friction.

Consider factors such as initial cost, volume discounts, shipping fee, payment terms, quality, warranty and support.

Spiral vibration dampers offer benefits such as reducing vibrations, improving safety, extending lifespan, reducing noise and enhancing performance.