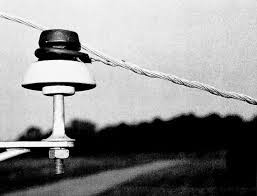

A slack span dead end is a segment of the transmission line designed to have lower tension compared to the main spans. It serves a specific purpose in the structural and operational integrity of the system. The slack span dead end helps manage the mechanical and environmental stresses on the system. They also provide lower tension which allows for flexibility and accommodates movement. It also acts as a buffer to absorb loads and vibrations to prevent excess stress on the main components. The slack span dead ends work with several components such as insulators, clamps, connectors and dead ends. Slack span dead ends serve at terminal points, directional changes and crossing applications.

Selecting the best slack span dead end

There are several slack span dead ends available in the market and serve different purposes. When selecting the dead ends, there are several factors to consider. These factors ensure the optimal performance, safety and reliability of the transmission line systems. The following are the common factors to consider when selecting the slack span dead ends.

- Mechanical load and tension needs – check the mechanical load that the slack span dead end must support. This includes the weight of the conductors, insulators and any extra hardware. Determine the suitable tension level to ensure the slack span can handle the forces.

- Environmental conditions – consider the impact of temperature fluctuations, wind speeds and ice accumulation. The selected dead end should accommodate ground movement and reduce stress.

- Geographical factors – check the terrain of the installation area to determine the necessary adjustments for the dead end.

- Conductor and hardware specifications – select the suitable conductor based on their electrical and mechanical properties. Select insulators and hardware that can withstand the lower tension of the slack span.

- Electrical load and voltage – ensure the slack span dead end can handle the specific voltage level of the transmission line. Assess the current carrying capacity of the conductors to avoid overheating.

- Structural support and stability – identify suitable anchor points that can hold the slack span dead end. Ensure the design of the towers can support the slack span dead end.

- Costs – consider the cost of materials for slack span dead end including conductors, insulators and hardware. Check the long term costs associated with installation and maintenance.

- Future expansion and scalability – the design of the slack span dead end should allow for upgrades or changes.

Installation procedures for slack span dead end

Installing slack span dead ends need careful planning and execution to ensure the system’s safety and reliability. Additionally, it is advisable to follow the provided installation specifications for the dead end. The following is a step-by-step guide to the installation procedure.

- Planning and preparation – conduct a thorough site survey to understand the terrain and environmental conditions. Develop a safety plan including hazard assessments and emergency procedures.

- Materials and tools preparation – gather all the necessary materials used with the dead end. These include conductors, insulators and fittings. Inspect all materials to ensure they are in good condition.

- Site preparation – clear the installation site of any vegetation that could interfere with the installation process. Install any temporary supports needed to secure conductors during installation.

- Anchor and support installation – identify and prepare anchor points for the slack span dead end. Install the anchors and ensure they are well aligned and capable of handling the mechanical loads.

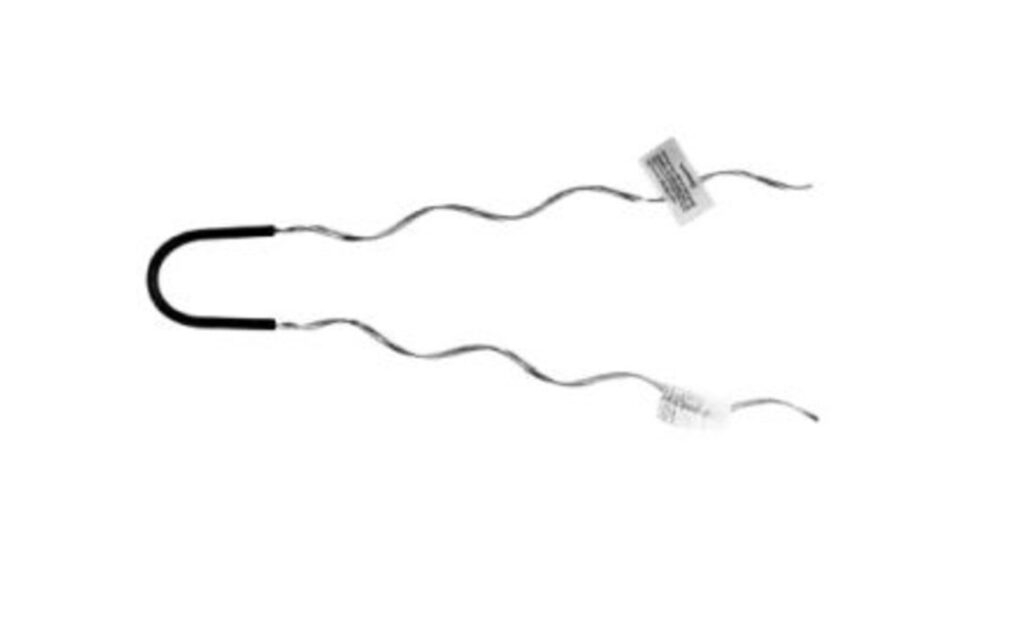

- Conductor preparation and installation – unroll and inspect the conductors for any damage and position them in place. Apply tension to the conductors to remove any slack suing tension meters to achieve the specified tension level.

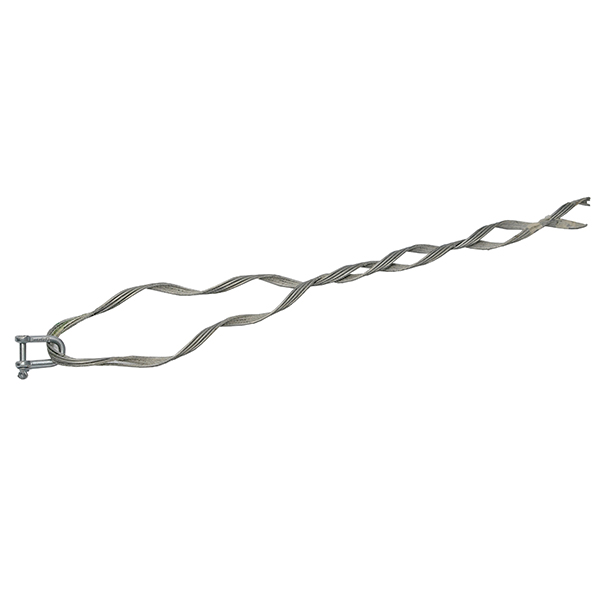

- Install insulators and hardware – attach insulators to the conductors and support structures. Attach dead end fittings such as clamps or connectors

- Final tensioning and adjustment – apply the final tension to the conductors and ensure they meet the specified tension levels. Make adjustments to the conductors and fittings to ensure proper sag and alignment.

- Inspection and testing – conduct a thorough visual inspection of the installation. Perform electrical tests to ensure proper conductivity and insulation.

- Documentation – keep a record of the installation process. This is including any adjustments, procedures followed and recommendations for maintenance.

Maintenance and inspection for the dead ends

Regular maintenance and inspection of the slack span dead end ensures its reliability and safety. It also helps to identify and address issues early to prevent failures. Additionally, it helps to maintain the reliability of the power transmission network. The following is a basic guide for maintenance and inspection for the slack span dead end.

- Perform visual inspection checking for signs of wear, corrosion or damage. Inspect for cracks, chips or contamination that could affect performance.

- Remove dirt, debris and bird droppings from conductors and insulators. This is to prevent electrical leakage and corrosion. Apply lubricants to moving parts and hardware to ensure smooth operation.

- Use tension meters to check the tension in the conductors and adjust as necessary. This is to maintain specified tension levels. Ensure the slack span dead ends maintain the correct sag to prevent excess stress.

- Replace any damaged insulators to maintain electrical integrity. Upgrade hardware components such as clamps or connectors.

- Inspect anchor points for signs of movement, corrosion or wear. Repair anchor points if they show signs of instability.

- Use thermal imaging to detect hot spots showing issues with electrical conductivity or insulation. Scan the slack span dead end components with a thermal camera to identify any unusual heat patterns.

- Measure the insulation resistance to ensure there are no leaks in the electrical insulation. Check the electrical continuity of the conductors and connections.

- Check for signs of corrosion or rust on metal components such as hardware, conductors and support structures. Apply corrosion resistant coatings to replace affected parts to prevent degradation.

- Keep detailed records of all inspections including findings, maintenance actions taken and any issues detected.

Troubleshooting process for the dead ends

Troubleshooting a slack span dead end involves identifying, diagnosing and resolving issues that could affect its performance. It ensures proper addressing of the problems and reduces downtime and prevent potential failures. The following is a troubleshooting process for the slack span dead ends.

- Identification of issues – regular inspections can identify early sings of problems. This is including unusual sagging, corrosion or damage to components. Use real-time monitoring systems to detect anomalies in tension, temperature or electrical conductivity.

- Initial assessment – conduct a visual inspection to check for sagging, fraying or breaks in the conductors. Check for chips, cracks or contamination.

- Diagnosis and analysis – categorize the issues by symptoms such as mechanical, electrical or environmental problems. Determine the potential causes of the issues . This could include excess tension, sagging, corrosion, or conductor damage.

- Root cause analysis – isolate the specific component causing the issue. Consider environmental and operational factors that might contribute to the problem.

- Corrective actions – based on the root cause analysis, develop suitable corrective actions. Adjust tension in the conductors to the specified levels. Carry out repairs as needed to ensure all work meets safety and operational standards.

- Verification – conduct detailed inspections to verify that the repairs have resolved the issue. Perform electrical and mechanical tests to ensure the slack span dead ends operates correctly.

- Preventive measures – check existing maintenance practices and update them based on the troubleshooting findings to prevent future issues. Provide training for maintenance personnel on identifying and addressing specific issues.

- Documentation – prepare a comprehensive report documenting the troubleshooting process. Describe the initial symptoms, analysis, repairs, and provide test results.

Community forums and interactions for slack span dead ends

There are several community forums and platforms with discussions on slack span dead ends. Joining such forums can be beneficial for networking, knowledge sharing and getting insights. The following are the popular community forums and discussions platforms for slack span dead ends.

- IEEE Xplore Digital Library and communities – these offer a digital library with extensive research papers, articles and conference proceedings on electrical engineering.

- T&D world community – this is a platform that provides news, articles and forums related to transmission and distribution systems.

- Eng-Tips forums – this is an online community for engineers across various disciplines including electrical and power engineering. It provides forums where professionals discuss technical issues and share solutions.

- Reddit – Reddit hosts subreddits where professionals and enthusiasts discuss electrical engineering topics.

- LinkedIn groups – these groups provide a platform where professionals discuss industry trends, share insights and seek advice on topics related to transmission systems.

- GlobalSpec – this provides forums and resources for professionals in various engineering fields. The electrical engineering community provides discussions on topics like transmission lines and slack span dead ends.

Frequently asked questions

Key components include conductors, insulators, dead end clamps, tensioning and anchor points. Each of these components help in maintaining the integrity and stability of the transmission line.

Consider the mechanical load, environmental conditions, electrical insulation properties, compatibility with existing transmission line components.

Common signs include excessive conductor sag, visible damage on hardware, and unusual tension levels, hot spots detected through thermal imaging.