A side tie is a component also known as a transposition tower or a transposition structure. It help on the overhead transmission lines to improve their electrical performance. The side tie counteracts the effects of inductive and capacitive reactance. This occurs due to the parallel arrangement of transmission conductors. Side ties install at specific intervals along the transmission line. This is to mitigate effects like line losses, increased voltage drops and interference with communication systems. The side tie consists of a tower where the conductors rearrange. This allows the conductors to cross each other at predetermined points. This transposition allows the balancing of the electromagnetic fields and reduce power losses. The side tie is therefore basically used to reposition the conductors. It also help mitigate the negative effects of inductive and capacitive reactance.

Components of side tie

A side tie has general components that work together to improve the efficiency of the transmission lines. The components however vary depending in the design and the requirement of the side tie. Other factors include voltage levels, line configuration and environmental conditions. The following are the main components of the side tie.

- Tower structure – the tower structure provides the support and stability for the side tie. It is from steel or concrete designed to withstand the mechanical loads and environmental conditions.

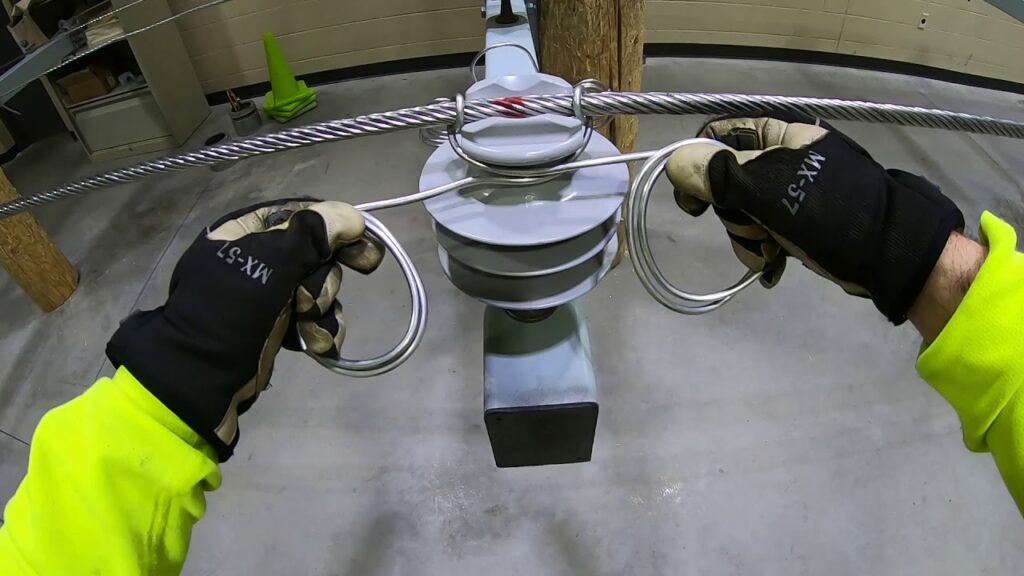

- Insulators – insulators help isolate the conductors electrically from the tower structure. They also prevent the flow of electrical current from the conductors to the ground to ensure a safe and efficient transmission.

- Crossarms – crossarms are horizontal bars or arms mounted on the tower structure to provide support for the conductors. They also help in maintaining the mandatory spacing and arrangement of the conductors.

- Conductors – conductors are an essential part of the side tie since they carry the electric current over long distances. They are from aluminum or aluminum alloy to withstand different weather conditions.

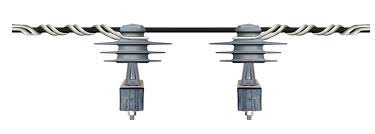

- Transportation devices – these devices help to facilitate the transposition of the conductors at specific points along the side tie. They include transportation brackets or spacer dampers which allow the conductors to cross over or under each other. This allows them to alter their position to achieve the desired transportation effect.

- Hardware and fittings – fittings such as bolts, clamps, connectors and strain insulators used to secure and connect the conductors, insulators, crossarms and transportation devices together.

- Grounding system – a system implemented to provide a path for the dissipation of electrical faults or lighting strikes. This ensures the safety of personnel and equipment by redirecting excessive currents away from the transmission line.

Types of side tie use on transmission lines

There are different types of side ties which depend on the specific requirements and designs consideration. Discussed below are the common types of side tie.

- Quad side tie – a quad side tie involves four transposition points along the transmission lines. The conductors transpose at each point which results in a more complex arrangement. This reduces the undesirable electromagnetic interactions.

- Single side tie – a single side tie is where the conductors transport at single point along the transmission line. This transposition balances the electromagnetic fields and minimize the effects of inductive and capacitive reactance.

- Delta side tie – delta side tie is also known as triangular transposition tower. This is is a specialized configuration where the conductors arrang in a delta shape. The delta side tie helps eliminates the effects of asymmetrical inductance in three-phase transmission system.

- Double side tie – a double side tie involves two transposition points along the transmission line. The conductors transpose twice allowing for enhanced cancellation of inductive and capacitive effects.

Applications of side ties

The applications of side ties revolve around improving the electrical performance, efficiency and reliability of overhead transmission lines. They help mitigate the effects of inductive and capacitive reactance. This is to achieve better control over electromagnetic phenomena. The following are the main applications of side ties.

- Voltage regulation – the transposition of conductors facilitated by side ties helps improve voltage regulation. Side ties reduce voltage imbalances and fluctuations to ensures a more stable and consistent power supply.

- Mitigation of inductive and capacitive effects – side ties help mitigate the effects of inductive and capacitive reactance. They also help balance the electromagnetic fields and minimize losses, voltage drops and interference caused by these effects.

- Long transmission line performance enhancement – side ties are beneficial for long transmission lines where the effects of inductive and capacitive reactance are more pronounced. Side ties optimize the performance of transmission system by reducing power issues and voltage drops.

- Power loss reduction – side ties play a crucial role in reducing power losses in transmission lines. They minimize the interaction between the magnetic fields generated by adjacent conductors. This results in lower resistive losses and improved overall system efficiency.

- Control of electromagnetic interference – side ties control electromagnetic interference caused by the transmission lines. They reduce the electromagnetic radiation and electromagnetic induction that can interfere with nearby communication systems.

- Improvement of line load sharing – side ties help to enhance the load sharing between the circuits. This is to achieve a more balanced distribution of electrical load among the circuits. Prevents overloading of individual circuits and ensuring better utilization of the transmission capacity.

Installation process of side ties

The installation process varies depending on the project requirements, tower design and local regulations. The installation process should be by professionals. This should follow industry standards and guidelines to ensure the safe and reliable operation. The installation process of the side tie involves a series of steps as discussed below.

- Determine the locations of the side ties along the transmission lines based on factors. These factors include line length, voltage level, electrical performance requirements and environmental conditions.

- Prepare the site area by clearing any vegetation or obstacles that may interfere with the construction process. The site leveled and made ready to accommodate the tower structure the tower structure.

- The foundation for the side tie constructed depends on factors as soil condition, tower design and load requirement. Such foundations include spread footings, drilled piers or concrete caissons.

- The tower structure includes the main tower, crossarms and other supporting elements erects on the prepared foundation. Cranes and other specialized equipment help to lift and position the tower component.

- Install the conductors by securing them to the tower using hardware like clamps, connectors and strain insulators.

- Transposition devices install along at the designated points along the side tie. They ease transposition of the conductors by allowing them to cross over or under each other.

- Insulators install on the tower to electrically insulate the conductors. This is prevent flow of electrical current from the conductors to the tower or ground.

- Establish a path for dissipation of electrical faults or lightning strikes. This involves installing grounding conductors and other components. This is to ensure safety of personnel and equipment.

- After the installation the side ties and entire transmission line are thoroughly tested. This is to ensure proper electrical performance, mechanical stability and adherence to safety standards.

Choosing the best side ties

There are various designs and types of side ties in the market that may make the decision-making process tedious. It is advisable to consult with professionals to provide guidelines on the best side ties. The following are the main factors to consider when selecting the side ties.

- The line configuration like the number of circuits and conductor arrangement, plays a crucial role in determining the number of side ties needed.

- The voltage level impacts the design, higher voltage levels may require additional spacing and insulation to ensure proper electrical performance.

- Consider environmental conditions when selecting side ties. This is to ensure they are able to withstand expected loads and the environmental stresses.

- The side ties has reliability and ease of maintenance. Consider factors such as corrosion resistance, accessibility for inspection and compatibility with standard maintenance practices.

- Ensure that the selected ties comply with regulatory standards, codes and requirements. This includes load-carrying capacity, clearance requirements and grounding provisions.

- Consider cost implications such as initial installation cost, ongoing maintenance cost and long-term operational benefits.