A shackle insulator is a type of insulator used to support and insulate the conductors in overhead transmission lines. It helps to prevent electrical current from flowing to the supporting structure. This helps to ensure the safe and efficient transmission of electricity. Its design allows some movement of the conductor under dynamic loads such as wind or ice. It also consists of a series of ceramic or composite insulating disks connected by metal links. The materials help to prevent corrosion and rust in various environmental conditions. The robust design contributes to the resilience of electricity grids in South America. Common types include porcelain insulators, polymeric insulators, strain insulators and compact shackle insulators. They find use in applications such as overhead transmission lines, distribution lines, transformer connections and high voltage applications.

Key features of shackle insulator

Shackle insulators have various features that help to make sure they remain a popular choice in the market. The following are the key features of the shackle insulators.

- Mechanical strength – shackle insulators have designs to withstand mechanical stresses and loads. This helps to ensure it can support the weight of the conductors and resist external forces.

- Flexibility and movement – they also allow for some degree of movement to accommodate the dynamic stresses. This also prevents damage to the insulator and the conductors during line movements and thermal expansion.

- Weight and size – their designs aim for an optimal balance between strength and weight. This is to ease installation and maintenance.

- High temperature tolerance – the insulators also ensure their performance in regions with hot climates.

- Insulating material – the insulators are from materials such as porcelain or composite materials. This helps to ensure effective electrical insulation to prevent leakage current. It also helps maintain the integrity of power system.

- Corrosion resistance – the metal components have coatings to resist corrosion. This is to ensure the longevity and structural integrity of the insulator.

- Leakage distance – their designs include specific leakage distance to maintain electrical insulation. This helps to prevent flashovers and ensure reliable performance.

- Hydrophobic properties – some shackle insulators are from composite materials. These materials help to repel water and reduce the risk of surface contamination.

Selection and installation of shackle insulator

Proper selection of shackle insulators focuses on designing and maintaining overhead transmission systems. It involves considering factors to ensure optimal performance and reliability. The factors include voltage rating, mechanical strength, insulating materials, leakage distance, regulatory compliance and cost effectiveness. The installation of shackle insulators is a critical aspect of setting up transmission lines. It should help to ensure the reliable and safe performance of the electrical system. The following is a step-by-step installation guide for shackle insulator.

- Safety precautions – ensure to follow all safety protocols using suitable personal protective equipment.

- Shackle insulators inspection – inspect each shackle insulators for any visible damages. Ensure the insulators meet the specifications required for the application.

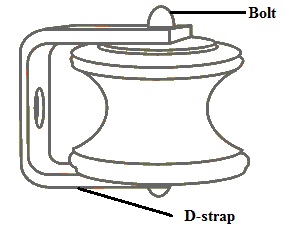

- Equipment preparation – gather the necessary tools and equipment for installation. This includes wrenches, insulator strings, bolts and nuts.

- Select installation location – identify the locations on the transmission or distribution line where the shackle insulators will install.

- Attach insulators to crossarm – attach it using suitable hardware and tighten to ensure a stable connection.

- Connect the conductor – install the conductor into the shackle insulator to align within the insulator’s groove.

- Attachment for sag – adjust the length of the insulator string to achieve the desired sag in the conductor.

- Tighten connections – ensure all nuts and bolts are tight to help maintain the mechanical strength of the installation.

- Clearance verification – check and verify clearance between the conductors and between the conductors.

- Final inspection – perform a final inspection of the installed shackle insulator. This is to ensure they meet quality and safety standards.

- Documentation – keep detailed records of the installation. This is including the type and specifications of the shackle insulators used.

Maintenance and inspection of shackle insulator

Regular maintenance and inspection of shackle insulators ensures the continued reliability and safety of the systems. It also helps to identify and address potential issues that may cause failures and accidents. Additionally, it is advisable to perform professional maintenance and inspection once in a while. The following is a basic guide for maintenance and inspection of shackle insulators.

- Establish a routine inspection schedule based on the environmental conditions. It also depends on the criticality of the installation.

- Conduct visual inspection of shackle insulators to check for any visible signs of damage. This include cracks, chips or discoloration.

- Clean the insulator surface regularly to remove dust, dirt and pollutants. This is through the use of a soft brush or low-pressure spray to avoid damaging the insulating material.

- Ensure the leakage distance of the insulator meets the requirements for the pollution severity of the area.

- Check the mechanical integrity of the insulator by inspecting the attachment points, bolts and nuts.

- Verify the sag in the conductor is within the specified limits and adjust the length of the insulator string.

- Ensure proper clearances between the conductors and nearby structures.

- Conduct ultrasonic tests to detect internal defects or cracks that may not be visible during a visual inspection.

- Apply suitable coatings to metal components to protect them against corrosion.

- Keep detailed records of maintenance activities, inspections and any corrective actions taken.

Comparative analysis of shackle insulators in South America

A comparative analysis of shackle insulators involves assessing and evaluating various factors. These factors include types, materials, manufacturers and the environmental conditions of the region. Additionally, it is advisable to seek professional help whenever in doubt. The following are the various factors to include in a comparative analysis in South America.

- Material – examine the materials used in the manufacture of shackle insulators. This is depending on the various environmental conditions in south America.

- Manufacturers and suppliers – identify the major manufacturers and suppliers of shackle insulators. Analyse their market share, reputation and the range of products offered.

- Performance – investigate how the insulators perform under loads and stress conditions. They should have the ability to withstand ice, wind and dynamic line movements.

- Hydrophobic properties – consider the hydrophobic properties of shackle insulators. This is especially in regions with high rainfall or humidity.

- Technological advancements – check the emerging technologies in shackle insulator design and manufacturing. This involves advancements in materials, manufacturing processes or smart technologies integrated into insulator systems.

- Cost analysis – compare the costs of the different types of the insulator. Consider the initial cost, installation, maintenance and the total cost.

- Corrosion resistance – assess the corrosion resistance of shackle insulators in areas with salt exposure.

- Environmental conditions – consider the environmental conditions across south America. This is including temperature variations, humidity levels, pollution severity and seismic activity.

Certifications and standards in South America

Shackle insulators comply to specific certifications and standards in south America. This helps to ensure their reliability, safety and performance in electrical transmission and distribution systems. Additionally, each south American country has its own set of standards and some adopt to various international standards. The following are the common standards for shackle insulators in South America.

- IEC standards – this provides international standards for electrical, electronic and related technologies for shackle insulators.

- ASTM standards – this provides standards for materials, products, systems and services. They regulate the hardness of rubber-like materials for shackle insulators.

- EN standards – this is a European standard that develops standards for electrical and electronic goods and services.

- ISO standards – this sets international standards across different industries for manufacturing processes and environmental impact.

- ANSI standards – this establishes standards for a wide range of industries including electrical equipment.

- BB standards – this issues standard for various industries including electrical systems.

Regional market for shackle insulators in South America

There are various factors that influence the regional market for shackle insulators in south America. These factors include demand, supply and market dynamics. Additionally, it is advisable to refer to industry reports, market research and market trends. The following are the factors that shape the regional market for shackle insulators in South America.

- Market trends – stay updated about current market trends and future forecasts for the shackle insulator market.

- Challenges and opportunities – identify challenges such as political instability, economic uncertainties or logistical issues. Also, look for emerging opportunities such as government initiatives.

- Economic factors – consider economic factors such as GDP growth, inflation rates and investment in the power sector. This contributes too increased infrastructure investments and demand for shackle insulators.

- Technological advancements – explore any technological innovations in shackle insulator design and manufacturing. Advanced features may influence purchasing decisions in the region.

- Environmental conditions – consider environmental factors such as pollution severity, humidity levels and seismic activity in different regions.

Frequently asked questions

A shackle insulator is a component that supports and insulated conductors in overhead transmission lines. It prevents electrical leakage and ensures safe and efficient power transmission in south American power systems.

South America has diverse environmental conditions such as pollution severity, humidity levels and seismic activity which can influence the choice of materials and design features in shackle insulators.