One kind of clamp used to support and fasten wires or conductors is the preformed tension clamp. It is sometimes referred to as a prepared dead end or a dead-end grip. Its primary purposes are anchor points, tension transfer and conductor security. For simple installations, the clamps have helical or pre-formed geometries. They are able to hold wires or conductors in place thanks to the design. It allows for some degree of movement while accomplishing this. This allows for expansion and contraction brought on by variations in temperature. Preformed tension clamps are from aluminum, stainless steel or galvanized steel. They can also maintain the right tension on the cables and make installation simple. Preformed tension clamps are dependable and guarantee the functionality and durability of the infrastructure. They work in telecommunications, distribution networks and overhead transmission lines, among other uses.

Components of a tension clamp that is premade

Preformed tension clamps are consisting of a number of components that cooperate to give the best possible performance. The clamp’s components change according on the application and design. They permit controlled movement while aiding in the anchoring of the wire or conductor. The preformed tension clamp’s common parts and components are as listed below.

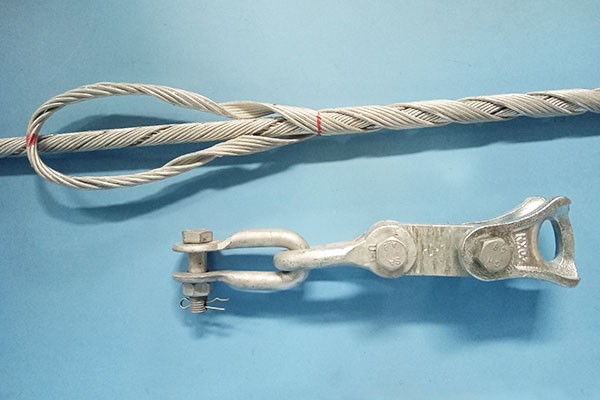

- Hardware – this is the set of fasteners used to attach the clamp to a support structure, such as bolts, nuts, washers and other similar items.

- Tensioning device – to change the tension delivered to the cable, certain clamps feature a tensioning device or mechanism.

- Clamp body – the primary part of the clamp that encircles the conductor or cable is the body. This serves to give the application stress and support.

- Insulation – these components aid in separating the clamp from the supporting framework.

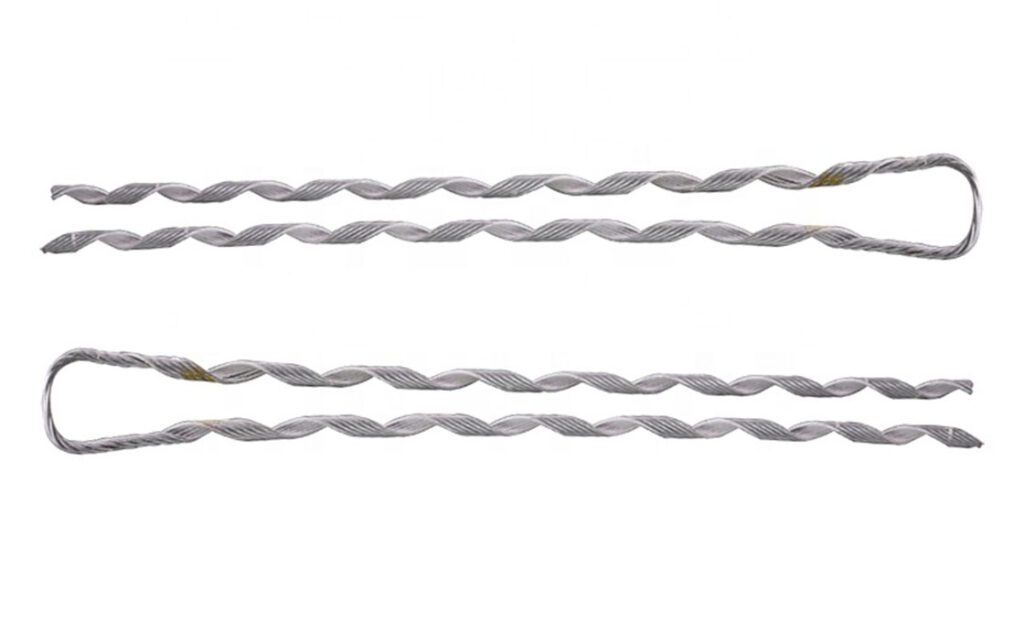

- Preformed shapes – these are wires that have already pre-shaped and integrated into the clamp body. They design a grasping device that secures the wire or cable.

- Armor rods – these give the cable extra defense against abrasion at the clamp attachment places.

- End fittings – these are extra parts that make it easier to attach the clamp to the support structure.

Features of the preformed tension clamp’s design

The preformed tension clamps’ design elements contribute to their ability to securely hold cables in place. Additionally, they let the cables to move in a regulated manner during expansion and contraction. The clamps’ lifespan, dependability and efficacy are all enhanced by their attributes. The preformed tension clamp has the following design elements.

- Preformed shape – the clamps have designs to fit the exact curve of the cable they are to support. This design ensures a secure grip without damaging the cable.

- High strength materials – materials like stainless steel and aluminum help make these clamps. The materials resist both the environment and mechanical stresses.

- Surfaces – they might feature rough surfaces on the inside to improve grip and stop slipping. A few of these mechanisms include gripping mechanisms like teeth or wedges.

- End termination – this can have hooks or shackles for attachment, or it can be a closed loop with an open end. The application and the way the clamp attaches to the other hardware determine the design.

- Adjustability – a precise change in the clamping force is possible with certain clamps thanks to their adjustable components.

- End fittings – to make installation easier, the fittings integrate into the prefabricated tension clamp design.

- Gripping mechanism – made of prefabricated wires, the clamps include a gripping mechanism. To offer many points of contact with the cable, the wires must be set. This contributes to increased stability and clamping force.

- Corrosion resistance – the clamps have coatings to withstand pressures and are from materials resistant to corrosion. This is shield the clamp from elements like dampness and wetness.

- Insulation – to avoid electrical contact between the clamp and conductors, the clamps have inuslation material coatings.

Why is using preformed tension clamps important?

Preformed tension clamps have significant advantages in a range of applications. Preformed tension clamps guarantee the dependability of electrical infrastructure, support cables and guard against damage. It’s also critical to choose clamps that best meet the requirements of your application. The significance of utilizing prefabricated tension clamps is as follows.

- Strong hold – the clamps give cables a firm hold that keeps them from slipping or drooping. This aids in preserving the dependability and integrity of the electrical grid.

- Tension maintenance – the clamps keep the cables’ tension at a constant level. This aids in avoiding excessive drooping, which causes inefficiencies in power transfer.

- Installation simplicity – In comparison to conventional clamps, the clamps are simpler to install.

- Lower maintenance – because of their sturdy design and dependable gripping mechanism, the clamps need less maintenance. Long-term performance remains guaranteed and ongoing maintenance costs decrease a result.

- Damage prevention – the clamps’ design guarantees that the cables remain in place without causing any harm. To lessen the chance of abrasion, the form and gripping mechanism spread the clamping force.

- Versatility – the clamps are adaptable and suitable for a range of uses. This covers telecommunications, distribution networks and overhead transmission lines.

- Durability – materials with high strength, including stainless steel or aluminum work in the making of the clamps. Because of this, they are strong and immune to deterioration, ultraviolet light and temperature changes.

The best prefabricated tension clamps to choose

The preformed tension clamp selection procedure aids in making the right choice for your needs. For best results, it also helps to select the premade tension clamp that best fits your needs. It is also a good idea to speak with electrical engineers who have installed power lines before. Depending on the specifications and circumstances of your power line project, they offer tailored advice. When selecting prefabricated tension clamps, keep the following things in mind.

- Conductor type and size – various clamp have designs to suit particular conductor kinds and sizes. Think about this and make sure they are compatible with the clamp.

- Material and corrosion resistance – check the materials taking into account the qualities of corrosion resistance. This is particularly true when operating in hostile areas.

- Application and line design – take into account the demands of the particular application and line design. Check to see if the tension clamp will function at dead ends, midspans, suspension points and other particular places.

- Tension and load capacity – verify the tension clamp’s tensioning and load capacity. Think about the conductor’s needed type of tensioning. This makes it easier to confirm that the clamp meets or exceeds the anticipated pressures and loads placed on the power line.

- Standards compliance – take into account the applicable industry guidelines and rules for the clamps. Safety, dependability and compatibility with the architecture of the electrical grid all depend on this.

- Manufacturers – check the manufacturers for dependability, quality, and customer service. Take into account the accessibility of manufacturer help, installation instructions and technical literature.

- Cost and budget – to guarantee quality, performance and longevity, take into account how cost-effective the tension clamp is. Examine features and costs offered by various manufacturers.

Comparisons and cost factors for preformed tension clamps

Examining the price of preformed tension clamps requires taking some things into account. These consist of the starting price, installation charges and upkeep necessities. Comparing preformed tension clamps to conventional clamps or other cable support techniques is also crucial. To aid in decision-making, it is also advisable to perform a cost-benefit analysis. When comparing the price of preformed tension clamps, keep the following things in mind.

- Purchase price at first – because of their particular designs, the clamps may cost more than standard clamps. Think about the advantages and improved performance that the clamps provide.

- Requirements for maintenance – the gripping mechanisms and durability of the clamps lower maintenance costs.

- Performance and dependability – when compared to conventional clamps, the clamps provide better performance and dependability. Their grasp is firm and they can hold their tension for an extended period of time.

- Industry compliance and standards – verify that the clamps adhere to all applicable industry guidelines and requirements. This is to guarantee dependability and compatibility. While adherence can help prevent future problems and expenses, it may also increase the upfront costs.

- Cost of installation – compared to conventional clamps, preformed tension clamp need less time and effort to install. This may result in lower labor and installation expenses as well as shortened project schedules.

- Lifecycle costs – take into account the costs related to both the tension clamps and the alternatives.

- Compatibility and customization – preformed tension clamp may be set to fit different cable diameters thanks to their customizable features. This guarantees peak efficiency and interoperability with the infrastructure.

Frequently asked questions

Preformed tension clamps are devices used to secure and support cables or conductors in various applications. They work by wrapping around the conductor and use a preformed gripping mechanism to provide a secure hold.

Consider the initial purchase price, installation costs, maintenance requirements and overall lifecycle expenses. The upfront cost of preformed tension clamps may be higher than traditional clamps. Their long-term benefits and performance advantages can justify the initial investment.

Preformed tension clamps find use in a variety of applications, including overhead transmission lines, distribution networks and telecommunication infrastructure.