A conduit standoff bracket is a device used to secure and support electrical conduit systems on lines. It creates a gap (standoff) between the electrical conduit and the support structure. This ensures proper clearance and maintain a safe distance between the conduit and the surrounding environment. Their design allows them to securely hold the conduit in place to prevent any direct contact with the support structure. Conduit standoff brackets are from durable materials that enable them to withstand harsh weather conditions. These materials are mainly steel, aluminum or galvanized steel.

Components of conduit bracket

A conduit standoff bracket consists of several components working together to provide safe and reliable transmission of electricity. They help the bracket to securely hold the conduit in place and create desired gap on the lines. additionally, the components provide reliable insulation o the overhead power lines for efficiency. The following are the main components of a certified conduit standoff bracket for safe installations.

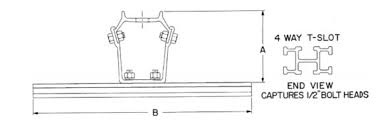

- Body – this is the main part of the bracket made from metal or plastic and provides the structure and support for the installation.

- Holes – the holes present in the body allow secure attachment to the pole or tower.

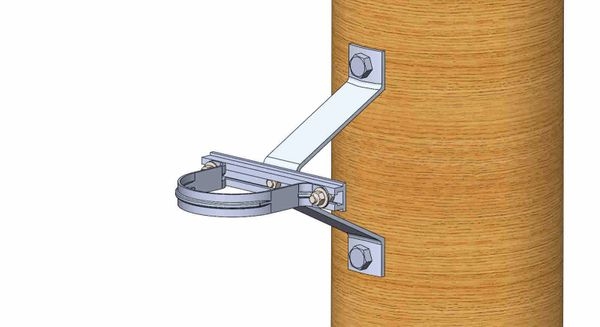

- Conduit clamp – this is the part of the bracket that secures the conduit in place which features adjustable mechanisms. The mechanisms include bolts, screws or straps.

- Insulators – insulators on the conduit standoff bracket provide electrical insulation between the conduit and the supporting structure.

- Fasteners – fasteners such as bolts, nuts, washers, screws and clamps help to secure the parts of the conduit standoff bracket.

Types of standoff brackets

There are various designs, sizes and types of conduit standoff bracket that work in the various applications in the industry. The selected conduit standoff bracket depends on factors such as the number and size of the conduits, installation environment and specific project requirements. The following are the common types of conduit standoff bracket.

Single gang conduit standoff bracket – this bracket supports a single conduit. It is mainly used in residential or commercial electrical installations. This type features a single clamp for securing the conduit.

Adjustable conduit standoff – this type allows for flexibility in positioning the conduit. It features adjustable clamps that move along the bracket body.

High-voltage conduit standoff bracket – these are brackets specifically designed for high voltage applications. This is to provide electrical insulation.

Multi-gang conduit standoff bracket – this type of conduit supports many conduits in a single unit. The multiple clamps allow for attachment of multiple conduits to a single bracket.

Universal conduit standoff bracket – these types of conduits hold different sizes of conduits. They feature interchangeable components that can adjust to fit different conduit diameters.

Applications of conduit brackets

Conduit standoff bracket find use in various applications for efficient transmission of electricity. Conduit standoff brackets organize, support and protect conduit systems to protect electrical wiring. The following are the common application areas of the high load capacity conduit bracket.

- Commercial applications – durable conduit standoff bracket work in commercial buildings for wiring, power outlets and communication systems in electrical installations.

- Residential construction – the brackets also work in residentials such as wiring in houses, apartments or condos. They are essential as they provide secure attachment and spacing for conduits within walls and ceilings.

- Data centers – conduit standoff brackets manage electrical wiring infrastructure in data centers and server rooms. This ensures proper organization and protection of wiring systems.

- Industrial facilities – the brackets secure conduits in areas such as manufacturing plants, warehouses and processing facilities. This ensures the safe routing of electrical wiring for equipment, machinery and control systems.

- Outdoor installations – conduit brackets support and protect outdoor applications. These applications include street lights, outdoor signage, parking lots and landscape lighting.

- High-voltage transmission lines – conduit brackets create clearance and maintain insulation between electrical conduits and supporting structures.

Installation process of standoff bracket

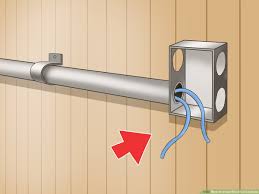

Easy installation conduit standoff bracket for transmission lines involves a simple procedure. The process however, varies depending on some factors. They include specific conduit bracket design, manufacturer’s instructions and local electrical codes. Some manufacturers and suppliers provide installation instructions for the brackets. Additionally, it is advisable to consult with industry experts or the installation guidance whenever in doubt. The following are the basic steps to follow during the installation process.

- Choose the mounting location for the bracket on the desired surface. Consider accessibility, conduit routing and clearance requirements.

- Ensure the surface is clean and free from any contaminants which might hinder the installation process.

- Position the bracket according to the desired conduit placement and spacing. Use a level to ensure the bracket is straight and properly positioned.

- Mark the locations of the mounting holes on the surface using a marker to serves as guides for drilling and securing the bracket.

- Drill the marked holes using the suitable tools and attach the bracket to the surface using appropriate fasteners.

- Install the conduit clamp onto the bracket after installing the bracket onto the mounting surface.

- Place the conduit clamp in place and carefully position the conduit into the clamp and secure it according to the clamps design.

- Test and adjust the conduit clamp to achieve the desired spacing and clearance. Ensure the conduit is securely held and test the stability and movement of the conduit.

Selecting the best conduit brackets for your application

Since there are various designs and types of conduit bracket, it may be hard to select the best bracket. The best conduit bracket is one that meets the specific requirements of your application. There are various factors to consider when selecting the conduit brackets. the factors are as discusses below.

- Determine the size of the conduit bracket and ensure it is compatible with the size of your conduit.

- Consider the budget and cost of the bracket by comparing prices and features from the available manufacturers and suppliers.

- Ensure the selected conduit bracket meets the relevant electrical codes, safety standards and industry regulations.

- Determine the desired standoff distance between the conduit and the mounting surface. Consider the insulation clearance, maintenance access and safety.

- Ensure the selected conduit bracket can withstand the different weather and environmental conditions. This helps in corrosion resistance and durability of the bracket.

- Consider the reputation of the manufacturer and consider quality production, installation instructions and compatibility with other components.

- Evaluate the weight and load requirements of the conduit. Ensure the selected conduit can support the weight and additional loads.