An armor rod is a tool designed to enhance durability and performance of the conductor cables. Armor rods take the center stage as guardians of these power lines. They protect the cables against bending and compression, abrasion and electrical faults. Armor rods are versatile and effective to maintain the infrastructures integrity. Common types of armor rods include aluminum armor rods, helical armor rods, thimble armor rods and composite armor rods. They are from various materials such as aluminum, steel and galvanized steel. The functions of armor rods vary depending on the type of rod, material and the application.

Functions of armor rod

Armor rods find use in various applications in the industry providing different functionalities. The function of armor rod depends on the type and material. The following are the functions of the armor rod.

- Physical protection – the rods protect the conductor from various physical threats. These include bending, abrasion and compression. Most of the damage is from cables weight, wind forces and accidental contact with machinery.

- Electrical protection – some of the armor rods help to mitigate the electrical risks on transmission lines. They reduce the risk of electrical discharge and corona discharge.

- Repairing damaged conductors – they are also used to restore strength and conductivity of damaged aluminum conductors.

- Strengthening damaged conductors – use of armor rods enhances their mechanical strength. It also enhances their resistance to fatigue caused by wind vibrations and other stresses.

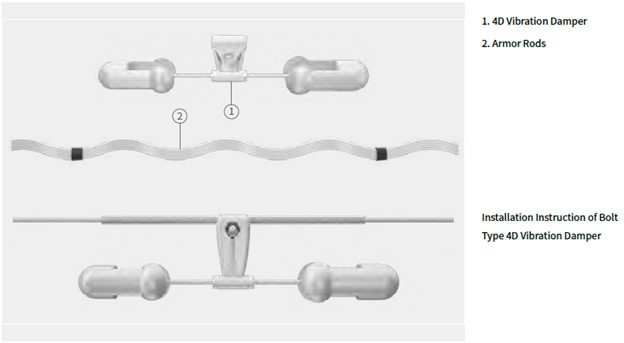

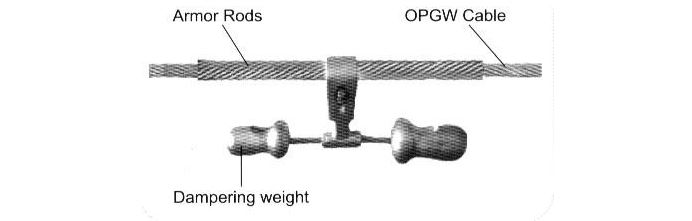

- Vibration dampening – armor rods help dampen vibrations in conductors. This in turn reduces fatigue and wear.

- Aesthetics – armor rods also improve the visual appearance of overhead transmission lines.

Features of armor rod

Armor rods have various attributes that aid in protecting overhead transmission lines. They also help to improve reliability and performance. The following are the various features of armor rod.

- Corrosion resistance – armor rods are from materials that resist corrosion. This is to ensure the lifespan and maintaining their structural integrity.

- Weight and density – lightweight armor rods reduce extra load on transmission lines.

- Helical design – they have a helical shape that provides flexibility to absorb vibrations and movements.

- Thimble structure – the thimble-like structure support at stress specific points along the conductor.

- Ease of installation – their design considers ease of installation to ease the maintenance.

- Electrical insulation – armor rods prevent unwanted electrical contact and ensure safety.

- Material – armor rods should be from similar materials as the conductors to resist abrasion. These materials include aluminum, aluminum-clad steel or composite materials.

Applications of armor rod

Armor rods are the protector of cables and conductors and ensure reliability and safety of transmission lines. The specific applications of the armor rod depend on preformed rods and helical rods. The installation requires specific knowledge and equipment. They have the ability to shield against physical threats, electrical dangers and fatigue. Additionally, it is important to consult with industry professionals for guidance on the best armor rod type. The following are the applications of armor rods.

- Power lines – the main purpose of armor rods is the armor rod is to protect the conductors on overhead power systems. They have the ability to prevent bending, abrasion and electrical dangers. Armor rods also help to rejuvenate damaged conductors and strength the existing lines.

- Telecommunications cables – armor rods safeguard communication lines from the same physical threats. They also protect them from physical damage and vibration especially in challenging underground.

- Construction – armor rods help in the construction industry in various ways. they help in reinforcing concrete barriers for added strength, protect guy wires from abrasion and stress.

- Vibration control – the rods also help to prevent aeolian vibrations which can lead to wear and fatigue. This helps to reduce the risk of damage and ensure the integrity of the transmission line.

- Maintenance – they are also used during maintenance and retrofitting activities. This is to reinforce existing transmission lines.

- Electrical insulation – the rods are from materials that offer electrical insulation properties. This helps to prevent unintended electrical contact and ensuring the safety of the system.

Benefits of using armor rods in your application

Using armor rods helps to ensure safety and reliability of the overhead transmission lines. They also offer several benefits that make them a popular choice in the electrical industry. The benefits also depend on chosen type, application and the installation quality. Additionally, it is advisable to assess the benefits of the armor rods to protect the infrastructure. The following are the various benefits of using armor rods.

- Physical damage – armor rods main purpose is to shield conductors from bending, compression, abrasion and impact. They also help to extend the lifespan and reduce the need for frequent repairs and replacements.

- Electrical protection – some types of armor rods help to reduce the risk of flash-over and corona discharge. This helps to prevent electrical faults and further extending conductor life.

- Improved conductivity – armor rods can restore the conductive capabilities to ensure efficiency. It also helps to reduce energy losses in various applications.

- Mechanical strength – use of armor rods to existing conductors makes them more resistant to fatigue and wind vibrations. This leads to fewer outages and improved safety.

- Vibration damping – some armor rods can dampen vibrations in conductors to reduce fatigue and wear. This contributes to stability to overhead transmission lines.

- Applications – armor rods find use in various applications in the industry. These applications include power lines, telecommunications and construction projects.

- Types and sizes – the armor rods come in helical designs, diameters and lengths to suit different conductor sizes.

- Simple installation – they come with various tools and techniques to help in easy installation and reduce disruption.

- Aesthetics – armor rods enhance the visual appearance of overhead lines especially in sensitive areas.

- Environmental benefits – the armor rods extend the lifespan of cables and conductors. This contributes to reduced waste and resource consumption.

What are the problems that armor rod fix on power lines?

Armor rods address several key problems on transmission lines and focus on preventing damage. They also help to extend the lifespan of the conductors. They also have the ability to address various physical and electrical challenges. This makes them a valuable tool for maintaining reliable and efficient electricity transmission. Additionally, it is advisable to understand the role and purpose of the armor rod before selection. The following are the various problems that armor rods fix in power lines.

- Severe damage – armor rods help to prevent damage to overhead transmission lines. This is by preventing major breaks or extensive corrosion.

- Maintenance neglect – regular inspection and maintenance help to ensure the proper functioning of the transmission systems.

- Improper installation – armor rods help to ensure proper installation of overhead transmission devices.

- Fatigue and aging – use of armor rod enhances mechanical strength and resistance to fatigue caused by wind and other dynamic stresses. This is beneficial for older lines or those in harsh environments.

- Damages – armor rods help in repair to restore their conductivity and delaying costly replacements.

- Vibration – they also dampen the vibrations from winds on the conductor to prevent fatigue and prevent potential breaks.

Frequently asked questions

Armor rod’s lifespan matches the conductor they are to protect which is 20-40 years with proper maintenance.

Preformed rods might be better for general protection which helical rods offer superior vibration damping.

There are certain types that can work for underground cable protection especially for fiber optic lines.

Armor rods can improve the visual appearance of overhead lines which makes them less prominent in sensitive areas.

There are various materials that are safe in the environment. Materials like aluminum and composite materials are more environmentally friendly.