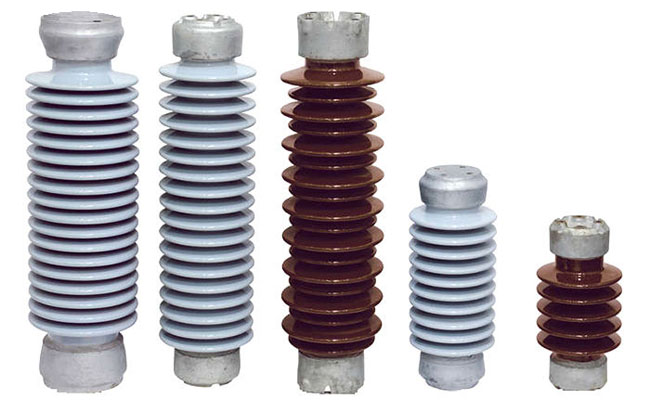

A post insulator is a device that supports and insulates the conductors from the support structure. It is sometimes referred to as a disk insulator. The construction is from of insulating discs placed in a stack, separated by metal fittings. Materials used to make these discs include porcelain, glass and composite materials. Post insulators aid to decrease corona discharge, which can cause power loss and radio interference. Post insulators stop the flow of electricity from the conductor to the tower pole, which could cause an electrical problem. They also offer mechanical support for the conductors, allowing them to endure wind and ice load. The use of post insulators on transmission lines helps to ensure that electrical power flows safely and efficiently.

Choosing the Best Post Insulator

There are various aspects to consider when choosing post insulators for your application. These elements contribute to the dependability and efficiency of the electrical system. Choosing the correct post insulator helps you meet electrical, mechanical, and environmental criteria. It also contributes to the reliable and efficient operation of transmission lines. The following are the considerations to consider when choosing post insulators.

- Voltage rating – check the voltage level of the project and select a post insulator with an appropriate rating.

- Material – consider the insulator’s substance and its ability to withstand environmental conditions. These materials provide electrical insulation, mechanical strength and weight.

- Mechanical strength – determine the mechanical requirements of your application. This includes conductor tension, wind and ice loads and earthquake factors.

- Corona performance – choose an insulator with specific shapes and finishes to limit corona discharge and increase electrical efficiency.

- Environmental conditions – think about a post insulator with good pollution performance. It should also tolerate environmental conditions. These include humidity, pollution, and UV radiation.

- Supplier reputation – consider the manufacturer’s reputation and track record. They should have a track record of delivering high-quality and dependable post insulators. Check the availability and quality of the manufacturer’s technical help and after-sales services.

- Cost effectiveness – determine whether the post insulator is cost effective and meets your application requirements. Compare the upfront expenses of various solutions to the total cost of ownership.

- Maintenance requirements – when selecting insulators, consider the ease of installation and maintenance. They should be simple to install and need minimal upkeep.

Applications of a post-insulator

Post insulators serve a variety of electrical applications that need insulation and support. They have designs to withstand specified voltage ratings, mechanical load requirements and climatic conditions. They also guarantee the safe and dependable operation of electrical equipment and systems. The next section describes the many different uses of post insulators in depth.

- Switchgear – insulators help to insulate and support switching devices. These include circuit breakers, isolators and load break switches in switchgear. They help to prevent electrical breakdowns and guarantee that the switchgear’s safe operation.

- Power transmission and distribution – they support and insulate the conductors of transmission lines. They also provide electrical insulation between the conducting components of the apparatus.

- Capacitor banks – use post insulators to support and insulate capacitor units.

- HVAC systems – the insulators support the busbars and other conductive elements in the switchyard. They provide insulation and mechanical support to ensure clearance and prevent electrical problems.

- Instrument transformers – insulators also function as current and voltage transformers. They provide both electrical insulation and mechanical support for the primary and secondary wiring.

- Railway traction systems – these use post insulators in electrified trains and traction systems. They aid to support and insulate overhead catenary or contact wires. They ensure that electrical power is efficiently transmitted to the trains. This occurs while ensuring sufficient electrical insulation.

- Telecommunication towers – insulators support antennas and transmission lines. They provide electrical insulation, preventing interference and ensuring consistent transmission signals.

- Substations – insulators support a variety of equipment, including transformers, circuit breakers, disconnect switches and bus bars.

- Surge arrestors – Insulators and surge arrestors operate together to safeguard electrical equipment. This may be due to lightning strikes or switching.

Installation techniques for post-insulators

Professional expertise is necessary during the installation process to avoid electrocution. Proper installation contributes to the dependability and safety of overhead transmission lines. Furthermore, it is advisable to adhere to manufacturer requirements and industry practices. This helps to ensure the successful installation of post insulators. The following is a basic installation of post insulators.

- Preparation – before installation, inspect the insulators for evident damage. Gather all necessary equipment, including post insulators, conductor hardware, fittings and safety equipment.

- Safety procedures – make sure to follow all the safety protocols and guidelines defined by relevant industry standards and local regulations.

- Positioning – determine the best position for the post insulators along the transmission line. Consider conductor sag, electrical clearance, and mechanical loading.

- Mounting arrangement – confirm the proper mounting arrangement for the specific type of insulator. Secure the mounting hardware to the support structure. This includes brackets, clamps and other fittings that keep the insulators in place.

- Lifting & handling – use appropriate lifting equipment to handle and position the post insulator. Avoid harming the insulators or the support structure during the process.

- Alignment – place the insulator with the mounting framework, making that it is level and perpendicular to the conductor.

- Installation on the structure – this involves attaching the post insulator to the supporting structure using the appropriate mounting hardware.

- Tighten and security – tighten all bolts, nuts and other fasteners to their torque settings. Inspect the installation for indicators of looseness or misalignment.

- Inspection – conduct a final visual assessment of the installed insulator to ensure proper alignment, attachment and condition.

- Documentation – keep accurate records of the installation. This includes insulation requirements, installation dates and any observations made during the procedure.

Maintenance procedures for post insulators

Post insulators in overhead and distribution networks should be properly maintained. This is to guarantee that the post insulator remains reliable and performs well over time. Furthermore, regular inspections help uncover possible problems early, allowing for appropriate response. It also helps to avoid unexpected failures. This is a simple maintenance instruction for post insulators.

- Conduct regular visual checks of post insulators to detect any visible symptoms of damage, contamination, or wear. Check for cracks, chips and other surface imperfections.

- In polluted places, inspect the insulator surfaces to see how much contamination exists.

- Ensure that the leakage distance along the insulator surfaces is free of foreign material. This is to guarantee that the necessary given creepage distance.

- Inspect the post insulator’s mechanical components, including the mounting hardware and fittings, for signs of corrosion or wear.

- Check the grounding system to ensure that the connections are secure and conductive. This is to ensure a consistent path for fault current.

- Use thermal imaging to detect any unusual temperature swings on insulator surfaces.

- Use corrosion-resistant coatings to defend against environmental corrosion.

- Keep detailed records of inspection dates, observations, and any maintenance tasks carried out.

Testing post insulators

Post insulators undergo testing to guarantee correct use, performance, and reliability. Some tests happen during manufacture and operation. They also help to guarantee that the post insulators meet the necessary criteria and are in good operating order. Furthermore, conducting such testing contributes to the correct performance of post insulators. The following are some frequent testing for post insulators.

- Visual inspection – examine the post insulators for any evident faults. These include cracks, chips, corrosion and surface contaminants.

- Mechanical load testing – subject the post insulators to mechanical load testing. This is to ensure their ability to endure the forces. It could include applying a static or dynamic load to imitate real-world situations.

- Corona testing – test the corona performance of the post insulators. Discharge can cause power loss and interference. Thus ensure that insulators can withstand corona effects.

- Thermal testing – this entails subjecting the insulators to thermal testing. This is to determine their performance under extreme temperature conditions. It uses thermal cycling to replicate the effects of temperature changes.

- Ultrasonic testing – this involves subjecting the insulators to vibration tests to determine their resistance to mechanical vibrations.

- Dimensional inspections – this involves measuring the dimensions of the insulators to ensure they fit the stipulated tolerances.

- Electrical insulation testing – this measures the insulation resistance and dielectric strength of the post insulator.

- Porosity testing – this helps to detect any internal flaws. This includes flaws that may impair their electrical function.

Frequently asked questions

The installation process for post insulators includes preparation, site inspection, positioning, mounting, lifting and placement, attachment to wires, alignment, tightening and securing, testing and inspection, documentation and maintenance.

Cracks, chips, contamination, corrosion, mechanical damage, electrical breakdown, corona discharge, porosity, and delaminations are some of the common flaws or concerns to check for in post insulators.

Common tests include mechanical load testing, electrical insulation testing, corona testing, porosity testing and thermal testing.