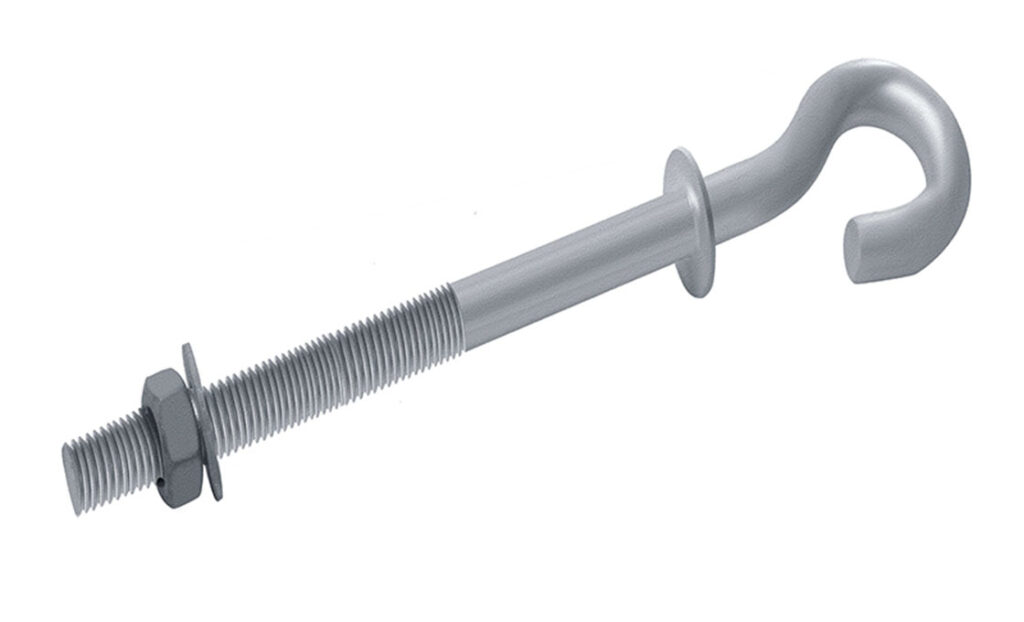

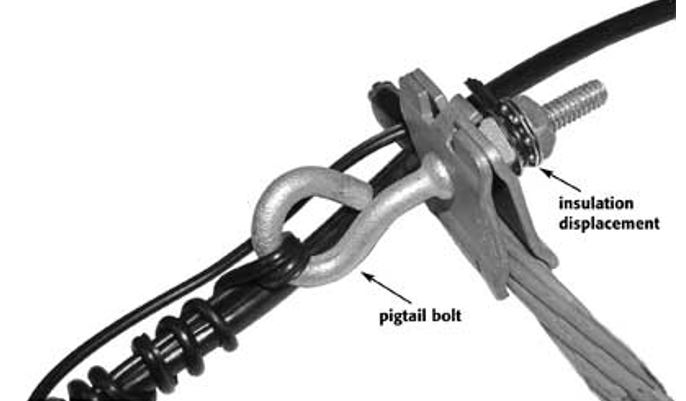

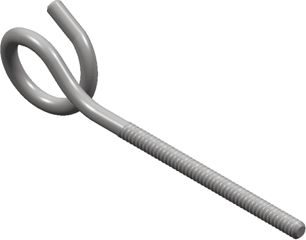

A pigtail bolt is a threaded bolt with a looped end for providing a point of attachment for other components. It is also known as a pigtail eye bolt, pigtail hook, pigtail screw, pigtail hook screw or pigtail fastener. Its main purpose is to secure cables to poles or other supporting structures. A pigtail bolt is from various materials that make them suitable in various applications. The robust fastener ensures the structural integrity of buildings and applications in South American conditions. Pigtail bolts are easy to install, strong, resistant to corrosion and available in various sizes and materials. Common types include pigtail eye bolt, electrical pigtail bolts, double arming bolts, pigtail thimble bolts and anchor pigtail bolts. They find use in various applications such as electrical, transmission systems, telecommunication and construction applications.

Key features of pigtail bolt

Pigtail bolt has various features that make them a suitable in various applications in the industry. It is important to assess these features before selecting to ensure they can support the expected requirements. The following are the key features of the pigtail bolt.

- Looped end design – this end allows for easy attachment for other components to provide a secure and reliable connection.

- Versatility – the pigtail bolts are available in different types and designs. This means they find use in various applications in the industry. These applications include electrical telecommunications and construction applications.

- Material – they are from high strength and durable materials like steel or galvanized steel. This helps to ensure resistance to corrosion and environmental challenges.

- Ease of use and installation – pigtail bolts are easy to install and remove for improved efficiency. This is because they can install by hand or use of other simple tools.

- Secure electrical connections – the looped end of the bolt help to ensure the secure and safe connection between wires. This helps to enhance electrical stability and safety.

- Reliability – they are also reliable which makes them usable in various applications. They mostly help in applications with need for strength and durability.

Selection and installation of pigtail bolt

The selection process for pigtail bolts is important as it ensure proper selection. It involves considering several factors such as cable size and diameter, material, load of the cable, environmental conditions and pe of clamp. Additionally, it is important to buy from a reputable manufacturer and check the specifications of the bolt. The installation of pigtail bolt is quite straightforward with simple steps. Also, it is advisable to consult with professionals whenever unsure about the process. The following is a simple installation process for the pigtail bolt.

- Preparation – gather all the necessary tools required for the installation process. This is including pigtail bolts, wrench, ladder, safety glasses and gloves.

- Installation location – determine the best location for the pigtail installation on the application. Consider the cable path and ensure the bolt provides adequate support and safety.

- Drilling – use the suitable tools to drill a hole on the surface where the bolt will install. Ensure the hole is deep enough to accommodate the entire length of the bolt.

- Pigtail bolt installation – insert the pigtail bolt into the drilled hole and thread the bolt through the hole until in contact with the surface.

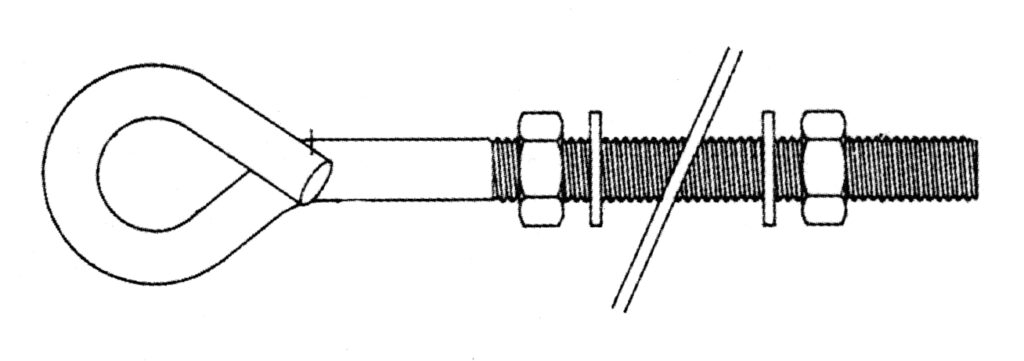

- Fastener attachment – place the washer on the other end of the pigtail bolt that extends beyond the surface. Thread a nut on the bolt and tighten using a wrench or by hand. Ensure the nut is tight to secure the cable to prevent damages.

- Cable attachment – connect the cable to the pigtail bolt using methods like cable clamp or a termination connector. Ensure secure connection and proper cable alignment.

- Inspection – conduct a final inspection of the installation to ensure secure connections of the cables and bolts. Check for any loose connections or signs of damage.

- Documentation – keep detailed records of the installation. This is including types, locations and dates of installation.

Maintenance and inspection of pigtail bolt

Maintenance and inspection of pigtail bolts helps to ensure the safety and reliability of electrical installations. It also helps to identify and address issues that could lead to potential failures. The frequency depends on factors such as environment, type of installation and the usage of the electrical system. Additionally, it is important to preform professional maintenance and inspection once in a while. The following is a basic guide on the maintenance and inspection in South America.

- Conduct regular visual inspections of pigtail bolts to check for signs of wear, corrosion or damage.

- Consider applying coatings such as galvanization or corrosion resistant materials. This is to protect against rust and corrosion.

- Periodically check the tightness and torque of pigtail bolts in construction and structural applications. This is to help ensure the integrity of the structure.

- Ensure the integrity of connections by checking for loose wires and signs of electrical arcing. Tighten any loose connections to maintain a secure electrical pathway.

- Inspect the anchor points to ensure they are securely fastened. This is especially in outdoor applications.

- Replace any bolts that show signs of significant wear, damage or deformation. It helps to prevent failures and ensures the continued safety and reliability of the installation.

- Maintain detailed records of inspections and maintenance. This is including dates, findings and any replacements made.

Comparative analysis of pigtail bolts in south America

Pigtail bolts are popular in the electrical installations in South America. Conducting a comparative analysis helps to ensure the proper selection of the bolts for your specific application. It involves considering the use of the bolts, size and type, cable load and installation environments. It is also important to assess the maintenance needs of the bolt before selection. Additionally, it is important to evaluate the reputation of the manufacturers available in the market. The following includes the factors to include in a comparative analysis in South America.

- Innovation and technology – evaluate whether the pigtail bolt manufacturers incorporate innovative features or technologies. The technologies should help enhance their performance or address specific challenges present in South America.

- Local availability – assess the availability of the pigtail bolts from different manufacturers. Consider the accessibility of spare parts and local support services.

- Durability – check the durability of the pigtail bolts by examining their expected lifespan under various conditions. They should maintain their structural integrity and reliability over time.

- Versatility – analyse the versatility of pigtail bolts in different applications across various industries. Consider how well they adapt in applications like construction, electrical, automotive and marine.

- Material – compare the materials used in the manufacture of the pigtail bolts. Assess their resistance to corrosion, rust and environmental degradation.

- Cost effectiveness – compare the costs of different bolts from the different manufacturers. Consider the initial purchase costs and durability.

Certifications and standards in South America

The selected pigtail bolts should comply with all the relevant standards and certifications in South America. These help to ensure the pigtail bolts are safe and reliable for use in various applications. There are various local set standards in each of the south American country. Additionally, it is advisable to consult with industry professionals when checking for the certifications. The following are the common certifications and standards in south America.

- ABNT NBR – this is a Brazilian standard that specifies the requirements for stele pigtail bolts.

- ISO certification – this certification signifies adherence to international quality management standards. It helps to ensure the quality and performance of the pigtail bolts.

- ANSI standards – this provides guidelines for various fasteners to ensure the bolts meets the recognized criteria for design and testing.

- ASTM standards – these are standards related to materials, dimensions and testing procedures.

- NEMA standards – this covers various aspects of electrical components ensuring safety and compatibility

Regional market for pigtail bolts in South America

The market for pigtail bolts continues to grow steadily from the increased demand. The demand is from the various applications in the industry including construction, utilities and telecommunications sectors. The growth of the economy also leads to increased demand for market growth. Also, it is advisable to assess the various market trends and dynamics that influence the demand for pigtail bolts. The following are the factors that shape the regional market.

- Renewable energy – the region continues to invest in renewable energy projects which creates demand for pigtail bolts.

- Competition from imports – importing pigtail bolts from other countries puts upward pressure on the prices. This influences the availability and demand for the bolts.

- Technology advancements – availability of new technologies such as 3D printing help to develop new and innovative pigtail bolts.

- Local production – the growing trend towards local production of pigtail bolts in south America also leads to increased demand of pigtail bolts.

Frequently asked questions

This is a type of fastener used to secure cables to poles and structures. They have threaded ends that inserts into a pre-drilled hole in the structure. The other end is usually bent into a hook or eye shape used to secure the cable.

There are various types of pigtails used in the different application sin South America. These include eye bolts, hook bolts, screw bolts, washer bolts and thimble bolts.