A downlead clamp is a customized bracket fastened to a tall transmission line. It aids in protecting and securing cables that descent from the power pole. Its main function is to keep the cable from swinging about in the wind. Storms or excessive wind can cause too much sway, which can cause damage. To lessen the strain on the cables and attachment points, downlead clamps help spread the cable’s weight. The clamp ensures that the various wires flowing down the structure are properly spaced apart. This lowers the possibility of becoming entangled. Depending on the particular cable type and application, its design changes. It can fix to the tower using attachment points and a clamping mechanism. Downlead clamps are from several materials, including galvanized steel and weather resistant materials.

Various downlead clamp types

Downlead clamps come in a variety of forms and styles for usage in overhead transmission lines. Every one of them is set to fit particular conductor combinations, installation specifications and weather conditions. Additionally, seek advice on the finest type for your applications from professionals in the field. The typical varieties of downlead clamps are as follows.

- Wedge downlead clamp – the conductor stays in place by a wedge-shaped component in these clamps. Without causing any harm to the conductor, it forges a tight and safe bond.

- Downlead clamps with insulation – these clamps have materials for insulation. They keep the conductor and the support structure from coming into touch electrically.

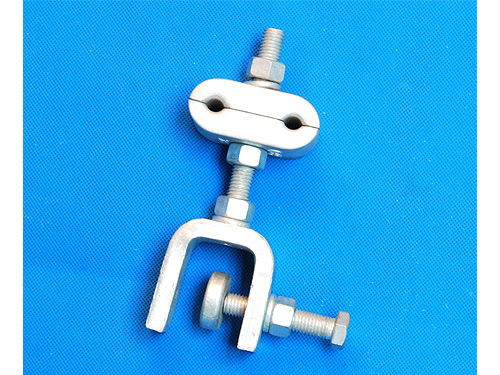

- Bolted downlead clamp – this type of connecting mechanism secures the conductors by bolting them together. Its two sides wrap together around the wire to create a strong and reliable grip.

- Spring-loaded downlead clamp – this keeps the conductor under constant pressure. It permits some flexibility while assisting in ensuring a firm grasp.

- Helical downlead clamp – this encircles the conductor with its helical construction. This facilitates a firm hold while permitting some mobility.

- Downlead clamp with parallel grooves – these include grooves that make installation and adjustment simple. They are mostly for conductors with parallel grooves.

- Compression downlead clamp – this fastens the conductor in position using compression fittings. They work in high-voltage settings where a dependable, low-resistance connection is necessary.

Parts of the downlead clamp

Downlead clamps consists of many parts that work together to hold the conductor and offer mechanical support. Depending on the downlead clamp type and design, different components are available. Together, the parts create a clamp that supports the conductor and guarantees dependable, safe functioning. The different parts of the downlead clamp are as follows.

- Clamping mechanism – the primary part of the clamp that grips the conductor is the clamping mechanism. It consists of compression fittings, bolts, wedges and springs. Their designs exert pressure while maintaining the conductor’s integrity.

- Clamp body – the clamp’s primary structural element is the clamp body that contains the clamping mechanism. It is from sturdy materials that give the conductor stability.

- Hardware – to install and attach the clamp, bolts, nuts, washers and screws are necessary. To survive environmental conditions, the fittings are from materials resistant to corrosion.

- Gripping surfaces – these are in direct touch with the conductor to offer a safe and firm hold.

- Insulation – this plays a useful role in preventing electrical contact between the supporting structure and the conductor.

- Mounting bracket – to give the clamp assembly extra stability and support, the clamps may mount on support structures.

- Protection against corrosion – the clamps have coatings to prevent corrosion. This contributes to the clamps’ longer longevity.

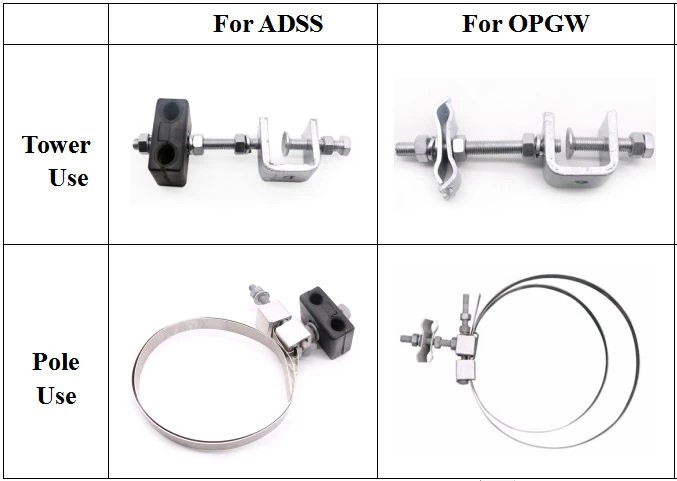

ADSS cable downlead clamps

All Dielectric Self-Supporting cables, or ADSS cables, work on overhead transmission lines. To ensure their regulated and safe drop, specific downlead clamps are useful. The support of ADSS cables comes from their unique non-metallic structure. The clamps have designs to withstand the demands and features of ADSS cables. Additionally, they aid in offering strain relief and a secure attachment in a variety of installation scenarios. It’s also a good idea to seek advice from industry experts on the ideal downlead clamp for your ADSS cables. The typical downlead clamps for your application are as listed below.

- Non-metallic construction – high strength polymers or composite materials should work to make the clamps. This is to ensure they are non-conductive and have great mechanical strength.

- Delicate grip design – downlead clamps for ADSS cables ought to have designs with a delicate grasp. By reducing stress concentrations on the cable, this design guards against fiber breakage.

- Tension distribution – ADSS cables are both mechanically and weight-supporting. Their layout lessens stress by distributing tension along the cable’s length.

- Suspension configuration – there may be designs for different suspension arrangements for the clamps. It also depends on what’s needed for installation. This is to provide a secure termination of the cable run.

- Strain relief – to allow for the motions, the clamps should have strain relief characteristics. At the same time, less strain is on the wires and their connectors.

- Hardware compatibility for ADSS – the cables need to work with various devices and accessories. This includes cable grips, pole fittings and suspension brackets.

- Installation ease – to ensure a smooth installation, specific tools and techniques are necessary for the cables.

The uses for downlead clamps

Downlead clamps provide overhead transmission lines with a number of crucial uses. The transmission infrastructure’s dependable and safe functioning is dependent on the functions. They play a significant role in the dependability and efficiency of overhead transmission lines. This is from fastening, sustaining and shielding wires or electrical conductors. The many purposes of downlead clamps are as follows.

- Protection against corrosion – a few of the clamps are from materials that resist corrosion. They aid in defense against external influences. This includes exposure to chemicals, dampness and salt spray. This contributes to the clamps longer life.

- Electrical insulation – between the conductors and the support structures, the clamps offer electrical isolation.

- Mechanical support – the conductors or cables get mechanical support from the clamps. This encourages the even weight distribution along the transmission line. By doing this, it avoids drooping that may result in mechanical damage.

- Alignment – downlead clamps aid in keeping the conductors in their correct alignment. Alignment preserves the integrity of the electrical system, minimizes losses and permits effective power transfer.

- Strain relief – to hold different factors, the clamps also let some movement of the conductors. They consist of wind-induced movement, thermal expansion and contraction and structural settling.

- Secure attachment – the clamps main job is to fasten electrical cables to structural supports. To keep the conductors from coming loose from mechanical stresses, the clamps hold onto them.

Advantages of employing downlead clamps

Downlead clamps in overhead transmission lines have some advantages. The transmission infrastructure’s effectiveness, dependability and safety result from this. This covers safeguarding, supporting and securing electrical conductors. Before choosing, it’s also a good idea to review the advantages and restrictions of each downlead clamp. The advantages of employing downlead clamps in your application are as follows.

- Installation simplicity – the clamps have an easy-to-install design that reduces installation expenses and time. This increases the transmission line installation process’s efficiency.

- Grip – downlead clamps provide a secure grip by holding the cables in place. This is to stop swaying, bouncing and unplanned movement that can cause damage or disconnect.

- Alignment – the clamps assist in keeping the conductors in the correct alignment throughout the transmission line. This is necessary to ensure the electrical system is reliable, lessen losses and send electricity .

- Cable management – to reduce the possibility of tangling, short circuits and power outages, the clamps maintain the appropriate distance between various cables.

- Ease of maintenance – structured infrastructure makes maintenance and inspection easier with correct cable management. As a result, there is less downtime and more operational efficiency.

- Adaptability – downlead clamps come in a variety of forms and styles. This guarantees that they can support a variety of tower layouts, applications and cable kinds. This allows for a smooth integration with the current infrastructure.

- Increased dependability – there is a lower chance of interruptions and power outages thanks to the safe and regulated fall. This guarantees steady and dependable power transfer, which boosts the economy.

- Durability – the clamps are from strong materials that can resist inclement weather and require little upkeep. As a result, the infrastructure and clamp life expenses reduce.

- Effective transmission – by using these clamps, wear and friction decrease and energy efficiency increases. Lower emissions and resource use result from this.

Frequently asked questions

This is a device used to secure and support electrical conductors or cables as they transition from overhead lines to support structures. Its main function is to provide mechanical support and strain relief to the conductor while ensuring secure attachment to the structure.

The clamps securely attach, support and protect electrical conductors reducing the risk of conductor sagging, stress or detachment. They also allow factors such as thermal expansion, wind-induced movement and environmental conditions.