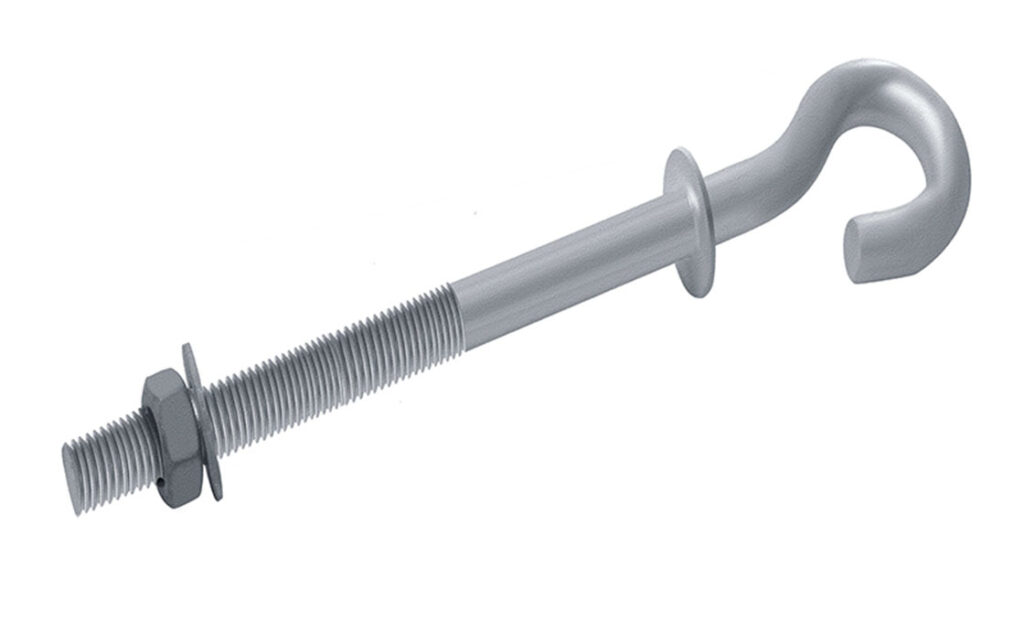

A pigtail bolt is a type of fastener used in overhead transmission lines to hang fittings on poles. They are also known as pigtail eye bolt, pigtail hook, pigtail screw, pigtail hook screw or pigtail fastener. The end of the pigtail resembles that tail of a pig hence the reference. Pigtail bolts are from high-strength materials such as steel or galvanized steel. These materials resist rust and corrosion for longer serviceable life. Pigtail bolts help to ensure the cables are properly secured to enhance safety and reliability.

Components of the pigtail bolt

Pigtail bolts have various components that work together to ensure stability and reliability. The specific components vary depending on the design and configuration of the bolt. The following are the main components of a pigtail bolt.

- Helical shaft – this is the main body of the pigtail bolt that allows easy installation by twisting it into the pole without need for drilling.

- Threaded end – the threaded end of the bolt helps the attachment of other fittings. This is to secure the overhead transmission lines and power transmission lines.

- Straight end – the opposite end of the helical shaft is straight to provide a surface for gripping and twisting the bolt into position.

- Hex head or eye – the hex head allows for easy installation using a wrench while the eyelet allows for direct attachment of suspension clamps.

Types of pigtail bolts

Pigtails have different types and configurations to suit different applications and installation requirements. The different designs of the pigtail bolts ensures a secure and reliable attachment of clamps and fittings. This contributes to the safety and performance of the power transmission system. The specific type of pigtail bolt selected depends on the application requirements. The following are the common types of the pigtail bolts.

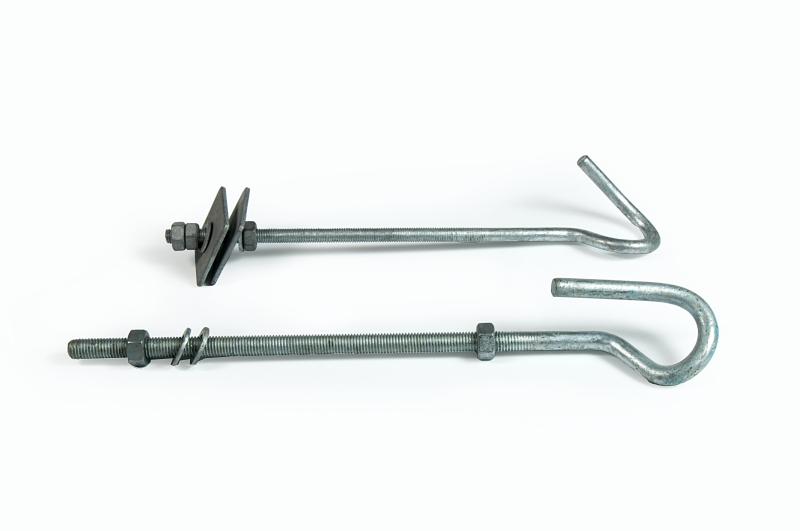

- Straight pigtail bolt – this is the standard type of the pigtail bolt with a straight, helical shaft that resembles the tail of a pig.

- Hex head pigtail bolt – this type has a hexagonal head at the threaded end that allows for easy installation.

- Eyelet pigtail bolt – this pigtail bolt has an eyelet loop at one end. This allows for direct attachment of suspension clamps or other hardware.

- Extended length pigtail bolt – the extended length pigtail bolts help to accommodate the different pole diameters.

Applications of pigtail bolts

High strength galvanized pigtail bolts find use in various applications in the industry due to their robust nature. They are easy to install and secures connections. Always select a pigtail bolt that best suits the specific application requirements. The following are the common application areas of pigtail bolts.

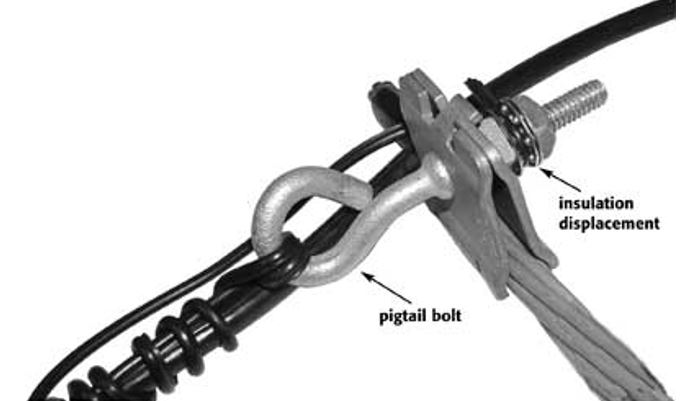

- Overhead transmission lines – pigtail bolts are commonly used to hang suspension clamps on power line poles. This provides a secure and reliable connection for supporting conductors and insulators.

- Telecommunications towers – pigtail bolts help to mount antennas, feeders and other equipment on communication towers.

- Outdoor lighting – pigtail bolts work in outdoor lighting applications to attach fixtures, brackets and other lighting components to poles.

- Utility poles – they also assist in attaching hardware and fittings to poles. They secure crossarms, brackets and other components used in power distribution and communication networks.

- Railway electrification – the bolts secure catenary wires, contact wires and other components used to power electric trains.

- Renewable energy projects – they also work in solar panel mounting systems and wind turbine installation to anchor support structures.

- Marine and coastal installations – pigtail bolts work in applications such as securing buoys, marine navigation aids and coastal fencing.

Pigtail bolts with easy installation

The installation of pigtail bolts includes a straight forward process. It however requires some care to ensure a secure and reliable attachment. Properly installed pigtail bolts play a critical role in the stability and safety of overhead transmission lines. Additionally, you should wear suitable safety equipment during the installation process and follow any specific guidelines provided by the manufacturer. Also, ensure you seek professional assistance for installation whenever in doubt. The following is a basic step-by-step guide on pigtail bolt installation.

- Ensure you have the correct size and type of pigtail bolts for your specific application. consider the pole material and diameter to select the suitable length of pigtail bolt.

- Mark the locations on the pole where you need to install the pigtail bolts using a marker or a pencil.

- Predrill the holes at the marked locations to ensure easier installation and prevent potential splitting of wooden poles.

- Hold the pigtail by the straight end and begin twisting it into the pole on the marked position.

- Continue twisting the pigtail bolt until the threaded end is fully engaged and securely embedded into the pole. Use a wrench to provide additional torque during installation.

- After the pigtail installs, attach the dead-end clamps or suspension clamps to the threaded end of the bolt.

- Perform a final inspection to ensure all the connections are secure and properly aligned.

Selecting the best pigtail bolt

Selecting the best pigtail bolt ensures the safety and reliability of the overhead transmission lines and other applications. The selection involves considering various factors. This is to ensure the bolt meets the specific requirements of your application. The following are the key factors to consider before purchasing the pigtail bolts.

- Consider the ease of installation for the chosen pigtail bolts. The installation should save time and labor costs during the project.

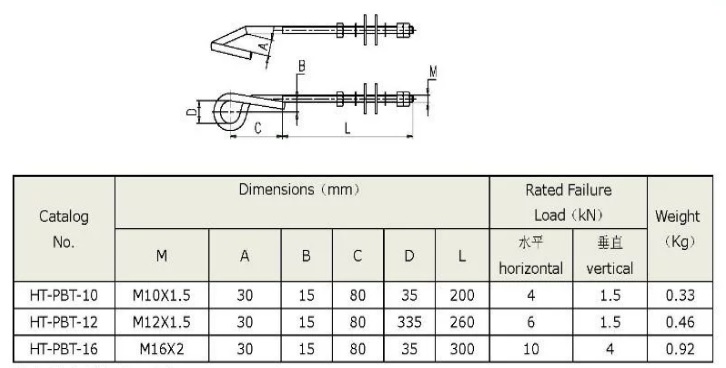

- Assess the load bearing capacity of the pigtail bolts based on the weight and stress the transmission lines will exert on the fasteners.

- Choose the type of pigtail bolt that suits your specific application. The type selected should offer easy installation and a direct attachment point for the other fittings.

- Select pigtail bolts made from high-quality steel that offers enough strength and durability. They should offer corrosion resistance which is essential for outdoor installations.

- Choose the suitable size of pigtail bolts based on the diameter of the pole or structure.

- Ensure the pigtail bolt meets the relevant industry standards and specifications for overhead transmission lines and power line installations.

- Select from reputable manufacturers known for producing high quality fasteners. This is to ensure a more secure and reliable installation.