A corona ring is a component used to control the corona discharge on overhead transmission lines. it is also known as grading ring or anti-corona ring. Corona discharge is the electrical discharge that arises when the electric field around the conductor becomes strong enough to ionize the surrounding air. It results in the production of audible noise, loss of power and damage to the transmission equipment. A corona ring is from metal or material with high electrical conductivity. It installs at appointed points along the transmission line such as ends of insulator strings or on top of transmission poles. Main types of corona ring include hanging corona rings, suspension corona ring, grading corona rings and stacked corona ring among others. They find use in applications such as transmission lines, substations, HVAC and HVDV systems and railway electrification among others.

Key features of corona ring

Corona rings have specific features and characteristics to effectively control and mitigate corona discharge. The specific features depend on voltage level, equipment type and environmental conditions of the installation areas. Additionally, proper selection, sizing and installation is vital to their effectiveness in controlling corona discharge. The following are the key features of a corona ring.

- High electrical conductivity – they are from materials with high electrical conductivity. They ensure effective distribution of the electric field and minimize corona discharge.

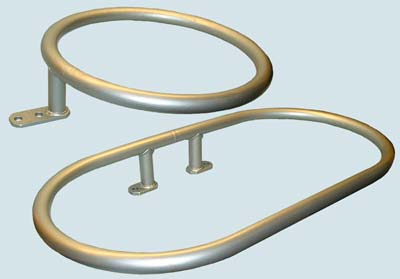

- Ring shape – this shape encircles the conductor or insulators to help distribute the electric field evenly. It also helps reduce the concentration of electric field strength at sharp points.

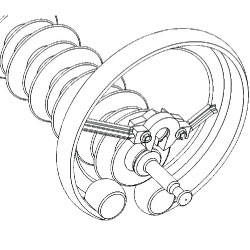

- Segmented design – these segments attach to the conductor or insulator in a circular pattern. This design helps break up the sharp edges and reduce corona discharge.

- Attachment points – the rings have attachment points that allow them to securely and safely fasten to insulators, conductors or support structures.

- Material compatibility – the materials should withstand the environmental conditions, exposure to weather, UV radiation and other factors.

- Insulating properties – the conductive materials prevent flashover or electrical breakdown by controlling the electric field.

- Easy installation – corona rings are easy to install and maintain which make them suitable for use in the field.

- Compliance with standards – the rings should comply with the industry standards to ensure their safety and performance.

Selection and maintenance of corona ring

There are various factors to consider when selecting the corona rings for a project to ensure effective corona control. These factors include voltage level, conductor size, environmental conditions, attachment method, design type, material selection, cost and insulation. Additionally, proper selection ensures the safe and efficient operation of high voltage electrical systems. Proper installation also ensures that the corona rings effectively control corona discharge. This also helps to contribute to the reliability and safety of the system. Also, it is advisable to always follow the manufacturers guidelines for installation. The following is a basic guide for the corona ring installation.

- Safety precautions – ensure you have all the personnel safety equipment and de-energize the transmission line.

- Tools and equipment – gather all the necessary tools and equipment for the installation provided by the manufacturer. These include wrenches, bolts, brackets and insulating materials.

- Location identification – determine the optimal location for the corona ring and refer to engineering drawings and specifications for guidance.

- Preparation – ensure the surface is clean and free from any contaminant that may affect the installation and performance. Clean the area off dust, grease or corrosion if necessary.

- Attachment method – use the suitable attachment method like bolting, clamping or welding. Tighten the clamps or bolts to the recommended torque specifications by manufacturer.

- Alignment and positioning – ensure the corona ring aligns and positions according to the design specifications.

- Insulation – if needed, attach the insulating material between the corona ring and the components attached to.

- Securing – secure the corona ring in place ensuring it firmly attaches to the structure.

- Inspection – conduct a visual inspection to verify that the installation completes correctly and no loose connections.

- Documentation – keep detailed records of the installation including dates, locations, personnel and any tests conducted.

Maintenance and inspection in Southeast Asia

Regular maintenance and inspection of corona rings ensures effective control of corona discharge in high-voltage electrical systems. It also helps identify any issues or wear that may compromise their performance. The frequency of maintenance and inspection depends on factors such as the operating environment, criticality of the application and manufacturer recommendations. The following is a basic guide on maintenance and inspection of corona ring in Southeast Asia environments.

- Conduct routine visual inspections of the corona rings and look for signs of physical damage, corrosion or contamination. It ensures they are securely attached and aligned with the components meant to protect.

- Clean the corona rings using a non-abrasive cloth or mild cleaning solution if there is signs of dust, dirt or pollutants.

- Check all the bolts, nuts, clamps or other fasteners used to secure the corona rings. This is to ensure that they tighten to the manufacturer’s recommended torque specifications.

- Replace the damaged insulation components to maintain proper insulation performance.

- Perform electrical tests to verify the integrity of the corona rings following the recommended testing procedures and frequency.

- Consider the environmental conditions in which the corona rings install including exposure to UV radiation, extreme temperatures and pollution.

- Keep detailed records of maintenance and inspection activities including dates, findings and any corrective actions taken.

- Replace the corona rings that show signs of damage and consider replacing them to maintain optimal corona control.

Comparative analysis of corona rings in Southeast Asia

Conducting a comparative analysis involves examining the application design, installation and maintenance practices of corona rings in the region. The analysis could vary due to the specific application, design, installation and maintenance practices. It also may vary depending on the environmental conditions and regional trends. The following is a basic comparative analysis of corona rings in Southeast Asia.

- Application of corona rings – they mostly find use in high-voltage transmission lines, substations and electrical infrastructure. They help reduce audible noise and enhancing system efficiency.

- Design and types of corona rings – there are various corona rings designs which includes suspension rings, grading rings and stacked rings.

- Environmental factors – southeast Asian countries have conditions such as increased humidity, heat and exposure to UV radiation. This may affect the materials used in corona rings and their effectiveness.

- Installation practices – the installation requires skilled technicians and engineers who understand the regions unique environmental conditions.

- Maintenance and inspection – maintenance should adjust to account for the potentially harsher environmental conditions in Southeast Asia. The countries have specific regulations related to environmental impact and pollution control which affect maintenance practices.

Certifications and standards of corona rings in Southeast Asia

The corona rings should comply to standards and certification in the region to ensure their effectiveness and safety. The environmental conditions and voltage levels also affect the performance of the corona rings in Southeast Asia. Additionally, it is advisable to consult with local regulatory authorities, industry associations and experts to ensure compliance with the relevant standards and regulations. The following are the relevant standards and certifications that may apply to corona rings in Southeast Asia.

- IEC standards – this provides guidance on the selection and dimensioning of high voltage insulators to prevent electric discharges.

- National standards – the regions may have their own national standards related to the electrical equipment. Specific countries have their own specific standards related to the corona rings.

- ISO certification – this provides the design, manufacturing and installation of corona rings for quality management systems.

- Local regulatory compliance – companies and utilities operating in southeast Asia must adhere to local electrical regulations and safety standards.

Regional market of corona ring in Southeast Asia

There are various factors that affect the region’s markets for corona discharge in Southeast Asia. These include the rapidly growing electrical infrastructure, urbanization and the need for reliable high-voltage systems. Also, the market also depends on government policies, economic conditions and industry developments. The following are the common factors affecting the region’s market for corona ring.

- Infrastructure development – the countries are investing heavily in expanding and upgrading their electrical infrastructure. This is to meet the demands of growing populations and industries this includes the construction of new high-voltage transmission lines.

- Urbanization – rapid urbanization in these regions increase demand for electricity and components like corona rings.

- Renewable energy integration – integration of renewable energy into the electric grid requires the efficient high-voltage systems.

- Energy efficiency – use of corona rings leads to the control of discharge which might lead to energy loss.

- Electrified transport – corona rings help mitigate corona discharge overhead catenary wires used in electrified transport.