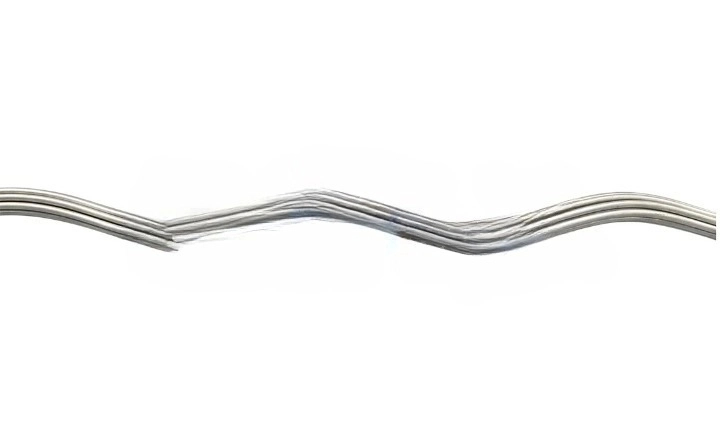

A line guard is a component used in the infrastructure of overhead transmission lines. It serves several functions to ensure the reliability and safety of power distribution. It is also known as a conductor guard. A line guard consists of helical rods that wrap around the conductor. Line guards also prevent direct contact, reduce wear and tear to extend the lifespan of the conductors. They also help to deter birds from perching on the conductors, protecting them from potential damage. Line guards act as dampers, absorbing and dissipating the vibrational energy. This protects the integrity of the conductors and reduces the risk of breakage. Line guards are from materials that are durable and resistant to environmental degradation. These include steel, aluminum, copper and composite materials. Line guards install by wrapping around the conductor manually or with specialized tools.

Features of a line guard

A line guard has several features that enhance its functionality and ensure the protection and efficiency of the systems. These features make it an indispensable component in the maintenance of transmission lines. They provide protection against mechanical wear, environmental factors and electrical faults. Their design and material choices reflect the role they play in the infrastructure of modern electrical systems. The following are the features of a line guard.

- Helical design – the helical shape allows the line guard to wrap around the conductor for consistent coverage. The design also simplifies the installation process allowing for manual application.

- Durable materials – line guards are from materials that can withstand harsh environmental conditions. They also have high strength to endure mechanical stresses and loads without breaking.

- Vibration dampening – the helical structure helps to absorb and dissipate vibrational energy. This helps to prevent conductor fatigue and prolong the lifespan of the power lines.

- Abrasion resistance – the line guards protect the conductor’s surface from abrasion caused by contact with other lines.

- Electrical insulation – some line guards have designs to provide extra electrical insulation between conductors. Line guards also help to reduce the risk of short circuits to ensure stable and reliable power transmission.

- Mechanical reinforcement – the guards provide extra mechanical support at critical points. This helps to ensure a secure attachment and reduces stress on the conductor. Its design also helps distribute mechanical loads along the conductor.

- Wildlife protection – some of the line guards have designs to deter birds from perching on conductors. This reduces the risk of damage from bird pecking or contamination.

- Customizability – line guards come in different sizes and specifications to fit various conductor diameters and configurations. They can have designs to meet specific environmental and operational conditions.

Applications of a line guard in the industry

Line guards are versatile components used in various applications within overhead transmission systems. They function in conditions aiming to provide essential protection against mechanical wear. Line guards play a vital role in maintaining the efficiency and safety of power distribution networks. Additionally, it is advisable to seek expert help for guidance on the best type for your application needs. The following are the common application areas of line guards.

- Overhead transmission lines – line guards protect conductors from mechanical and environmental damage. They also reduce wear and tear due to vibrations, weather conditions and physical contact.

- Distribution lines – they work in high voltage and lower voltage distribution networks. They ensure the longevity and reliability of conductors in urban and rural areas.

- Areas with high wind exposure – this includes areas with frequent high winds such as coastal areas or open plains. They reduce wind-induced vibrations which can lead to fatigue and failure.

- Icing and cold regions – line guards help to prevent ice accumulation and reduce abrasion caused by ice movement.

- Urban and industrial areas – the guards protect conductors from pollution, bird droppings and other contaminants. They also help reduce maintenance issues and contamination.

- River crossings and long span installations – conductors on river crossings and other wide gaps face higher mechanical stress. The line guards provide extra mechanical support and stability for the installations.

- Railways and highways – overhead line crossing railways and highways need extra protection. This is due to higher risk of mechanical impact. Line guards also help protect the conductors from potential damage due to contact with equipment.

- Renewable energy installations – line guards work in renewable energy installations. These installations face harsh environmental conditions. They ensure the reliability of power lines in areas with significant weather fluctuations.

Industry updates and advancements for conductor guards

Line guards have seen several updates and advancements in recent years. This is as driven by technology innovations and increased demand. Line guards’ industry is evolving with significant advancements in material science, engineering innovations and smart technologies. These advancements enhance the performance, reliability and safety of power transmission systems. Additionally, it is important to seek guidance on the different updates for the best performance of your application. The following are the latest industry updates and advancements in line guards.

- Advanced materials – there are new composite materials such as fiber reinforced polymers. These materials provide high strength-to-weight ratios and better corrosion resistance. Nanomaterials improve the performance characteristics of line guards for better resistance.

- Improved vibration dampening technologies – this includes the use of tuned mass dampers that are more effective in reducing vibrations. These devices have designs to match the natural frequency of the conductor. Some systems use sensors and actuators to adjust the dampening properties in real-time.

- Enhanced design and engineering – there is design improvement of helical rods for better performance. This is including improved gripping strength and more uniform pressure distribution. Some of the line guards have aerodynamic designs that reduce wind resistance and cut vibration-inducing forces.

- Smart monitoring and IoT integration – modern line guards have sensors that track various parameters. This is including vibration levels, temperature and mechanical stress. Integration with IoT platforms allows for remote monitoring and predictive maintenance.

- Customization and adaptability – manufacturers offer more customized solutions tailored to specific environmental conditions. Some of the guards have modular designs which allows for easier installation and replacement of damaged sections.

- Research and development – continuous research and development efforts lead to new innovations in line guard technology. Advanced simulation tools and rigorous testing protocols help to develop and confirm new designs.

Supplier or vendor information for line guards

Selecting a supplier for the line guards involves evaluating several critical factors. This is to ensure you choose a reputable supplier for your specific needs. The right supplier will help to ensure the best performance and longevity of your overhead transmission lines. The following are the factors to consider when selecting a supplier for line guards.

- Specific requirements – understand the specific needs of your project. This is including the type and size of conductors. Estimate the number of line guards needed and establish your budget constraints.

- Research potential suppliers – look for suppliers with a strong reputation in the industry. Ensure the supplier offers a comprehensive range of line guards and related accessories that meet project needs. The supplier should have extensive experience in supplying line guards for similar projects.

- Product quality and standards – check the materials used in manufacturing the line guards. High quality materials are the best for durability and performance. Ensure the products follow relevant industry standards and certifications. Also, compare the technical specification for the line guards from different suppliers.

- Technical support and services – test the level of customer support provided by the supplier include after sales. Ensure the supplier has technical experts who can assist with product selection andinstallation guidance.

- Pricing and delivery – compare prices from different suppliers to ensure you get the best value. Bulk purchase may result from discounts or special pricing. Assess the supplier’s delivery capabilities. This helps to ensure timely availability of products for your schedule.

Working voltage range for line guards

The working range for line guards vary depending on the specific design, materials and intended application. The line guards function in medium to high voltage transmission and distribution systems. Choosing the right type and specification contributes to the reliability and efficiency of your power infrastructure. Also, it is advisable to consult with manufacturers to get detailed specifications and recommendations for your needs. The following are the voltage ranges for a line guard.

- Medium voltage lines – these include applications in distribution networks, industrial facilities and urban infrastructure. This ranges between 1kV to 69kV.

- High voltage lines – they work in applications in regional transmission networks and inter-city power lines. Voltage ranges between 60kV to 230kV.

- Extra high voltage lines – these work in ultra-long distance transmission lines. eThe voltage ranges between 230kV to 800kV.

- Ultra high voltage lines – these includes ultra-long distance transmission lines in large power grids. This includes voltage rating above 800kV.

Frequently asked questions

Line guards act as vibration dampers by absorbing and dissipating the energy from wind-induced vibrations.

Consider the quality, technical support, reputation, pricing and delivery, warranty and return policies.

Recent advancements include use of advanced materials, improved vibration dampening and integration of smart monitoring.