The Horizonte wind farm is a significant milestone in Chile’s renewable energy, marking a collaboration between ENERCON. This partnership concluded in the creation of South America’s largest wind farms. It also showcased advanced technology and a commitment to sustainable energy solutions. The project features 140 ENERCON E-160 EP5 wind turbines, each with a capacity of 5.83 MW, totaling 816 MW. The turbines mount on custom-designed steel towers standing 95 meters tall. The ENERCON E-160 EP5 turbines deployed at Horizonte incorporate cutting-edge features. These include an advanced direct drive system that enhances efficiency and reliability and a robust design for extreme conditions. With a rotor diameter of 160 meters, the turbines are engineered to withstand the Atacama Desert’s extreme temperatures and wind speeds. Hotline tap clamps are crucial components in optimizing Chile’s renewable energy targets.

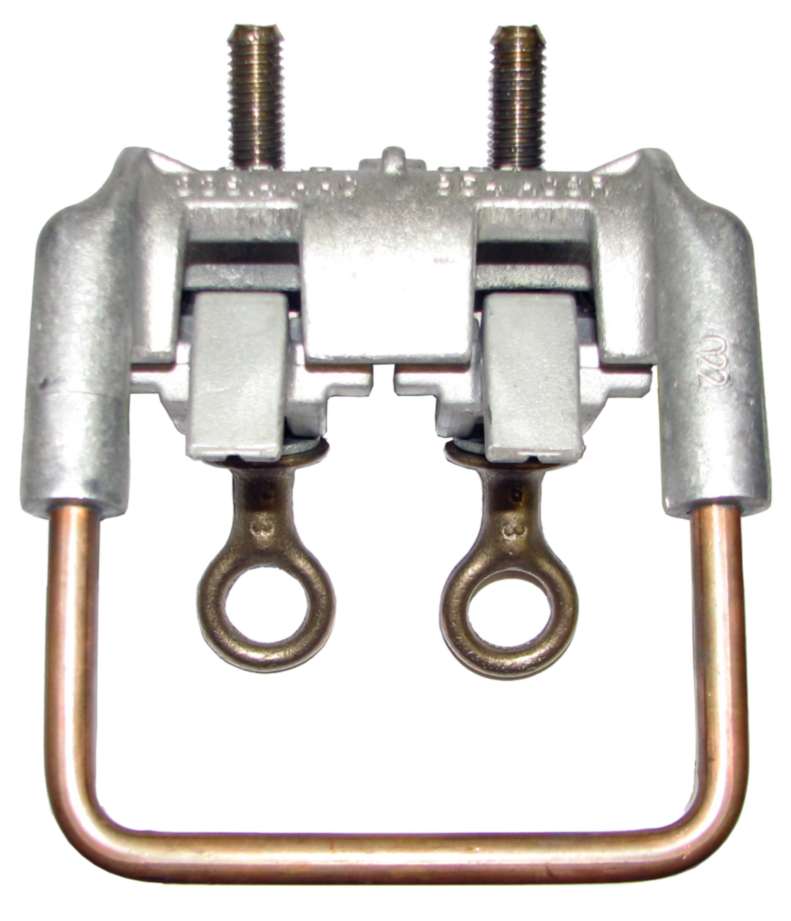

Hotline tap clamps are also known as live-line clamps or hotline connectors. They are crucial in large-scale wind farms like the Horizonte wind farm in Chile. They enable safe, efficient power transmission from wind turbines to the grid without the need for shutdown. A hotline tap clamp is a specialized electrical connector used to tap into line power lines and branch electrical connections and ensure low-resistance, high-conductivity joints to prevent energy loss. They serve in medium-voltage and high-voltage transmission lines. Hotline tap clamps enable repairs without shutting down the entire sections of the wind farm. High-performance tap clamps help splice lines between the wind farm’s substation and the main grid.

How Chile’s Horizonte wind farm powers homes

The Horizonte wind farm generates enough electricity to power Chilean homes. Each of the wind turbines converts kinetic wind energy into electrical power. Electricity is initially produced at low voltage, and on-site transformers boost voltage for efficient transmission. Cables link many turbines to a central substation. Key technologies supporting wind energy in Chile include substations, smart grid technology, and battery storage. Horizonte’s substation transforms electricity from 33 kV to 220 kV for long-distance transmission. The use of battery storage helps balance intermittent wind generation in Chile. Hotline tap clamps allow maintenance crews to add new turbines without disrupting power flow. They help reduce resistance and energy loss across long-distance cables.

The relevance of hotline tap clamps in wind farm development

Hotline tap clamps play a crucial role in the electrical infrastructure of the Horizonte wind farm in Chile. They ensure reliable, efficient, and safe power transmission. They help maintain high-voltage transmission lines with minimal downtime. Hotline tap clamps ensure efficient energy transmission, grid stability, and minimal downtime. Discussed below are the functions of hotline tap clamps in wind farm development.

- Reliable electrical connections—hotline tap clamps attach tap conductors to main transmission lines and ensure uninterrupted power flow. The clamps are key in interconnecting the 140 wind turbines to the power grid.

- Live-line maintenance—hotline tap clamps can be installed while the transmission line remains energized. This helps reduce power disruptions during the installation, maintenance, and potential future expansion of the wind farm.

- Grid stability and load distribution—hotline tap clamps help distribute electrical loads evenly, reducing stress on the grid.

Key technologies utilized in the Horizonte wind farm in Chile

The Horizonte wind farm is the largest wind farm and most advanced in Latin America. The project utilized various technologies to ensure efficient energy generation, sustainability, and reliability. These technologies will continue to shape the future of wind energy in South America. Discussed below are the technologies supporting the Horizonte wind farm in Chile.

- Advanced wind turbines – the wind turbines used feature direct-drive systems for high efficiency and lower maintenance. They also feature a 160-meter rotor diameter designed to capture more wind energy.

- High-voltage transmission and grid integration—high-voltage substations and transmission lines ensure the transfer of energy over long distances. Hotline tap clamps enable live-line work and reduce downtime during maintenance.

- Smart wind farm management—the use of a SCADA system—allows real-time monitoring of wind turbine performance and grid conditions. Remote control and automation enable operators to adjust turbine settings based on wind conditions.

- Sustainable construction and environmental adaptations—specialized turbine foundation designs ensure stability in seismic-prone and desert soil conditions. Dust- and sand-resistant coatings applied to turbines and electrical components help withstand the extreme Atacama Desert climate.