A ground rod is a component that ensures the safety and proper operation of overhead transmission cables. It is a metal rod thatpenetrates into the ground to create a low resistance channel for electrical current. Ground rods safeguard the system from lightning and fault currents, ensuring voltage stability. They help limit electromagnetic interference, ensuring the stability of the electrical system. Ground rods are from materials that are both conductive and corrosion-resistant. These materials include copper, galvanized steel, and copper-clad steel. Ground rods can have a single material or a series of parts that join to form the appropriate length.

The elements of the ground rod

Ground rods for overhead transmission lines originate of various components. These components help to guarantee proper grounding. Each of these components has a distinct purpose in ensuring the grounding system’s best performance. The ground rod consists of the following components.

- Grounding conductor – this connects the ground rod to the transmission tower or pole. The size depends on the current-carrying requirements. They are usually from copper or aluminum for their high conductivity and corrosion resistance.

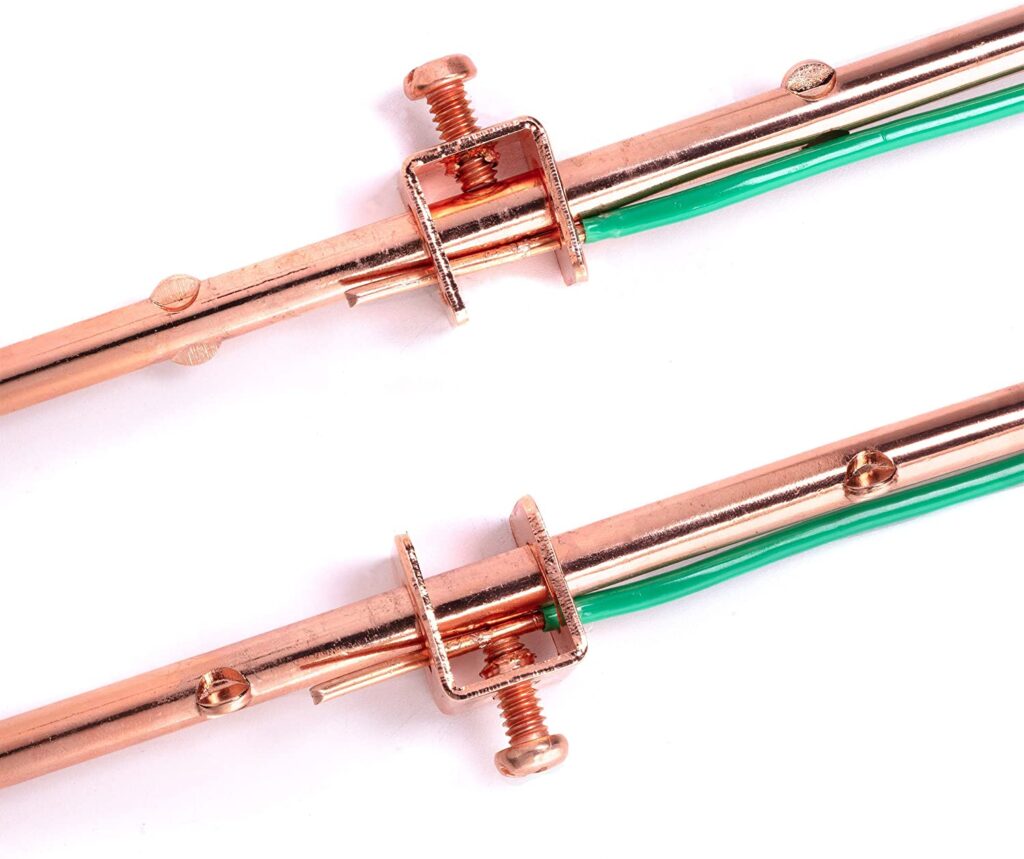

- Ground clamps – this secures the grounding conductor to the ground rod. It is from materials such as copper, bronze or other corrosion-resistant alloys. Common types include mechanical clamps, compression connectors or exothermic welds.

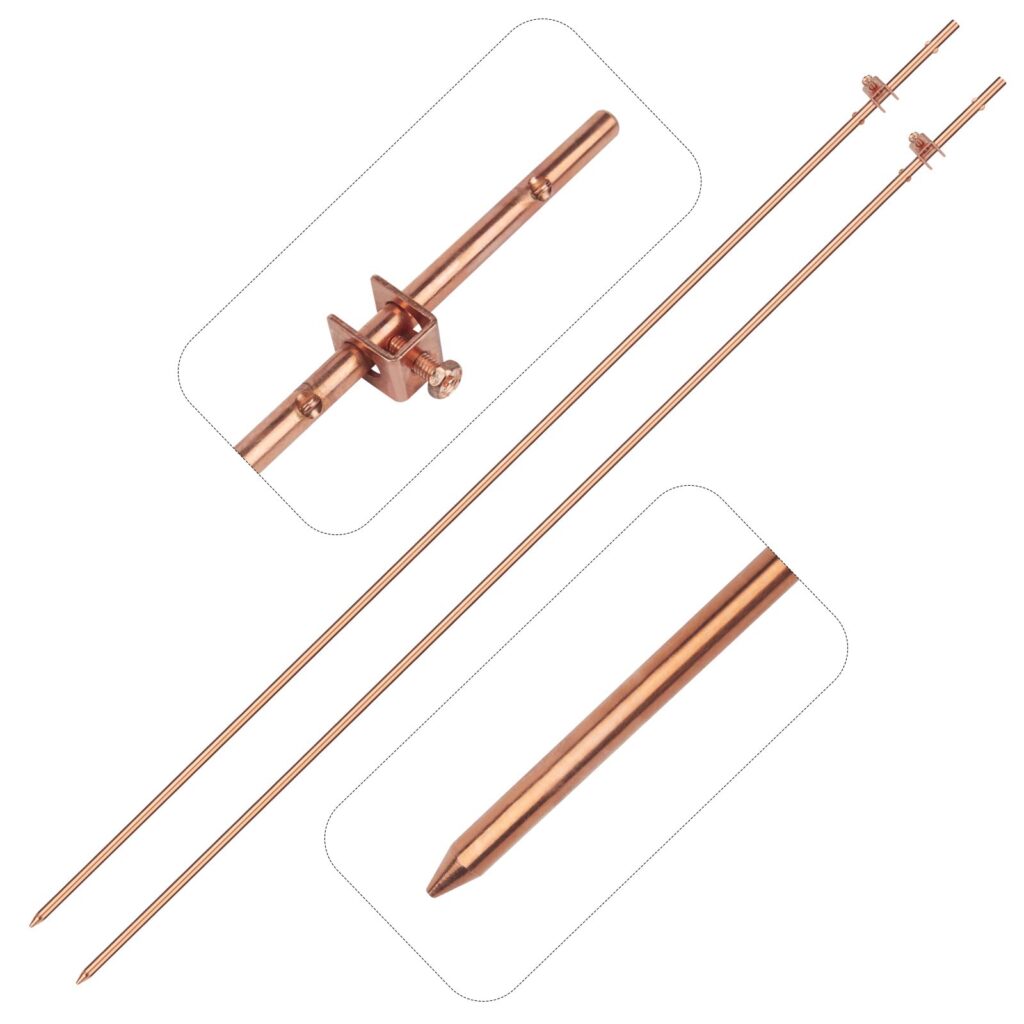

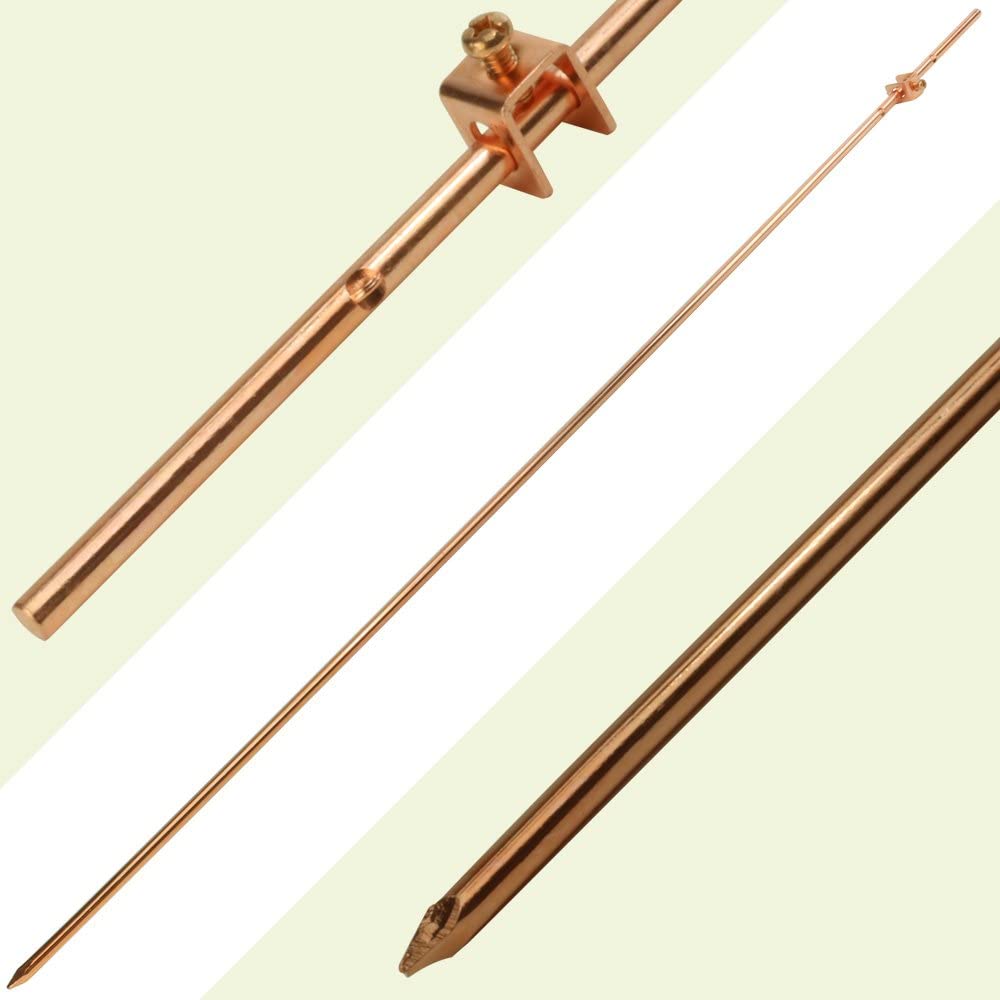

- Ground rod – this is the part that drives into the ground to dissipate electrical currents. It is from materials like copper, galvanized steel or copper-clad steel. The length and diameter varies depending on the soil conditions and local regulations.

- Ground enhancement material – this improves the conductivity around the ground rod. This is especially in areas with poor soil conductivity.

- Ground rod driver tool – this may be manual or powered to drive the ground rod into the ground. Types include sledgehammer or hydraulic drivers.

- Inspection and maintenance components – this includes ground rod cover that protects the top of the ground rod from physical damage. Test wells provide access to the ground rod connection for inspection and testing.

Primary Characteristics of a Ground Rod

Ground rods have distinct characteristics that ensure their grounding effectiveness in electrical systems. These attributes contribute to their durability, conductivity, and ease of installation. These characteristics additionally make them dependable components for grounding systems. This protects electrical infrastructure from lightning strikes and fault currents. The ground rods have the following features.

- Length and diameter – the ground rod length is typically 8 to 10 feet but can vary based on soil conditions. Common diameters are 5/8 to 3/4 inches to provide enough surface area for effective grounding.

- Corrosion resistance – ground rods have coatings to resist corrosion to extend their lifespan in harsh soil conditions. The rods undergo galvanization to enhance their resistance to corrosion.

- Material – copper has excellent conductivity and corrosion resistance. Galvanized steel is cost effective compared to the other materials. Copper-clad steel combines the conductivity of copper with the strength of galvanized steel.

- Ease of installation – the ground rods may have pointed or tapered ends to ease driving the rod into the ground. Some have a sectional design to reach the desired depth.

- Conductivity – materials like copper ensure low resistance to provide an efficient path for fault currents and lightning strikes.

- Mechanical stability – the ground rods are strong to insert into various soil types without bending. Some rods have steel core that provides extra mechanical strength. This is while maintaining good conductivity.

- Versatility – the ground rods are suitable for use in various soil conditions with enhancements. This helps to improve performance in poor soil conditions.

- Compliance with standards – the ground rods must meet standards set by NEC and IEEE to ensure safety and effectiveness.

- Connection points – the clamping area is a design that provides a secure connection point for grounding conductors. They also have smooth surfaces to ensure a good electrical connection without grounding clamps.

The objectives of ground rods in overhead transmission lines

Ground rods serve many applications on overhead transmission lines and electrical systems. They focus on safety, dependability, and system integrity. This happens by protecting the equipment, guaranteeing system stability, and safeguarding personnel. The ground rods in overhead transmission lines provide the following reasons.

- System stability and performance – ground rods establish a stable reference point for electrical system’s voltage. Proper grounding helps to reduce electromagnetic field interference which can disrupt the operation of communication systems.

- Equipment protection – ground rods help protect transformers, circuit breakers and other critical components from surges. They also help prevent corrosion of metal component in the transmission lines and substations.

- Safety enhancement – ground rods provide a low-resistance path for lightning currents. This helps the currents to dissipate into the ground. This reduces the risk of damage to transmission lines and equipment. Ground rods help to direct the fault current into the earth.

- Operational reliability – ground rods help maintain the continuity of the electrical circuit and ensure uninterrupted power supply. The rods also help in stabilizing the system’s ground potential to reduce voltage fluctuations.

- Safety grounding – the rods ensure all exposed conductive parts of the electrical systems are at earth potential. This is to reduce the risk of electric shock to personnel working on the system. They provide a path for electrical faults to flow into the ground.

- Regulatory compliance – the rods also ensure compliance with national and international electrical standards. They also include features that allow for easy inspection and testing. This is to ensure compliance and functionality.

Accessories used with ground rods

Ground rods are compatible with a variety of accessories to enable appropriate installation, connection, and maintenance. These components contribute to a reliable, secure, and long-lasting grounding system. They also ease proper installation, improve conductivity, and guard against environmental damage. Further, the selection and use of these accessories contributes to the safety and reliability of electrical systems. The following are the accessories used with ground rods.

- Ground enhancement material (GEM) – this helps to improve soil conductivity around the ground rod. They include bentonite clay, conductive cement and chemical grounding compounds.

- Couplers – these connect the sectional ground rods to reach greater depths. They feature threaded or compression-types and match the ground rod for compatibility.

- Ground clamps and connectors – these connect the grounding conductor to the ground rod. Common types include mechanical clamps, compression connectors and exothermic welds. These clamps provide a secure and permanent connection to offer a durable and conductive connection.

- Driving sleeves and tips – driving sleeves protect the top of the ground rod during installation. Such precautions help to prevent damage and deformation. The driving tips ease the penetration of the ground rod into hard or rocky soil.

- Test wells and inspection pits – these provide access to the ground rod connection for inspection, testing and maintenance. They also include a cover to protect the connection point from environmental elements.

- Ground resistance testers – these measure the effectiveness of the grounding system. They test the resistance between the ground rod and the earth.

- Anti-theft devices – these prevent the theft of copper ground rods in areas where metal theft is a concern. They include locking mechanisms that secure the ground rod and make it difficult to remove.

- Protective covers – the covers protect the exposed part of the ground rod from environmental damage, physical damage and corrosion. They are from durable, weather resistant materials.

Problems and obstacles with using ground rods

Ground rods are critical components in maintaining proper grounding in overhead transmission lines. Yet, its application presents some obstacles and issues. Their efficiency is mostly determined by soil conditions, corrosion, installation challenges, and maintenance issues. Also, overcoming these difficulties necessitates careful planning, appropriate materials, and ongoing maintenance. The following are the obstacles and issues associated with the use of ground rods.

- Corrosion – soil composition, moisture and salts can speed up the corrosion of ground rods.

- Installation challenges – driving ground rods into rocky or compacted soils can be difficult which increases labor.

- Soil resistivity – soils like sandy, rocky, or dry soils have high resistivity which makes it difficult to achieve a low resistance grounding system. Soil resistivity varies depending on depth and moisture content.

- Cost – high-quality ground rods can be expensive especially materials like copper or copper clad steel. Labor, equipment and ongoing maintenance add to the cost of an effective grounding system.

- Environmental factors – changes in soil moisture due to weather conditions can affect the resistance of the grounding system.

- Ground rod theft – copper ground rods are valuable and can be targets for theft. This poses a security issue and disrupts the grounding system’s integrity.

Frequently asked questions

A ground rod is a component driven into the ground to provide a low-resistance path for electrical currents to dissipate into the earth.

Soil resistivity varies with soil type, moisture content and temperature which affects the grounding system’s resistance.

Ground rods provide safety, system stability, equipment protection and regulatory compliance in overhead transmission lines.