A ground rod coupling is a component used to attach two or more ground rods together. This helps create an unceasing path for electrical grounding, hence the name “coupling”. They are mostly made of copper or galvanized steel to disperse electrical current to the ground. The coupling helps to ensure there is a low resistance path for electricity in case of a sudden increase in current. This also helps to prevent a probable fault in the system. The galvanized steel ground rod coupling is effective to improve the safety and reliability of the grounding system used in the power transmission lines. The main types of coupling are the threaded and compressed coupling for creating a continuity between the rods.

Components of a coupling

Copper ground rod coupling for electrical systems is from different components working together to improve the efficiency of the systems. The available components in a single coupling vary depending on the size of the ground rod, application and local regulations. The main components of the threaded ground rod coupling are as discussed below.

- Body – this is the main component of the coupling which is responsible for linking the ground rods together. It is a cylindrical structure used to enclose the ends of the ground rods.

- Threads – the threaded ends enable the coupling to attach securely to the ground rods and ensure a tight and reliable connection between the rods and the coupling.

- Fasteners – fasteners include bolts, nuts and washers used to fasten the coupling to the ground rods tightly.

Types of a ground rod couplings

Power transmission lines include various uses of the ground rods based on factors like size of the grounding system, materials of the ground rods and the specific requirements of the grounding system. The type of coupling to use should be compatible with the available components of the power transmission line. The following are the main types of ground rod coupling.

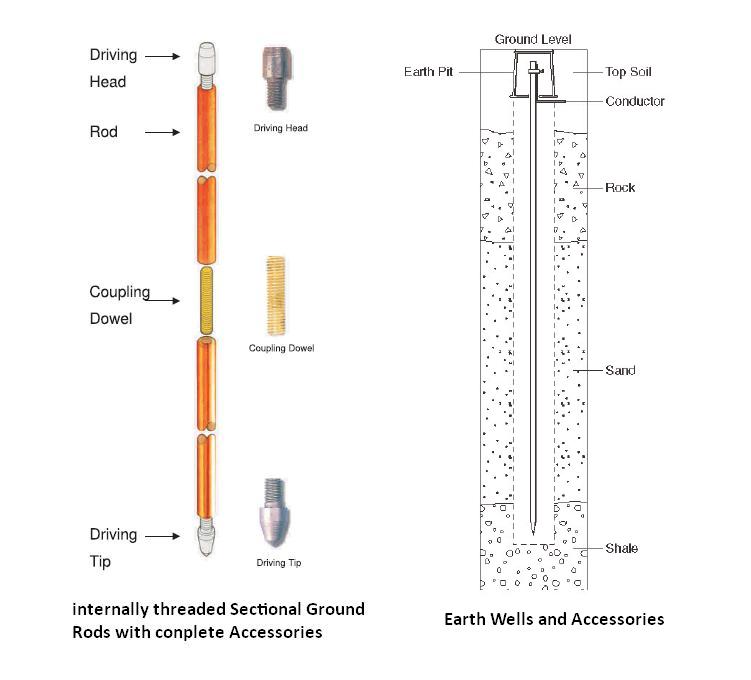

Threaded coupling – this type of coupling has threads on the inside of the sleeve which allows it to screw on the threaded end of a ground rod. Threaded ground rod coupling is popular used for smaller grounding systems.

Compression coupling – compression couplings use a compression mechanism to secure the coupling to the ground rods. They have a sleeve with a spring inside which allows them to expand when the ground rod compresses.

Bolted coupling – these couplings have two halves that enclose the ends of the ground rods. The two halves join together using fasteners such as bolts and nuts to create a secure connection. This allows them to provide a high level of mechanical strength for grounding systems.

Exothermic welding coupling – the couplings use a specialized welding process to generate a permanent and low-resistance connection between the ground rods. These are mostly used in critical grounding systems since they produce excellent conductivity.

Applications of coupling

Specific applications of the ground rod coupling vary depending on the local electrical codes, regulations and industry standards. Ground rod coupling is often used to connect two or more ground rods together, extend the reach of a ground rod and repair a damaged ground rod. These helps them to be applicable in the following areas:

- Substation grounding – the coupling ensures proper electrical grounding to the substation gear. This is mainly through connecting the grounding conductors to the ground rods using couplings. This creates a low-resistance path for dispersing faulty currents into the ground.

- Grounding systems – coupling helps to establish effective grounding systems to protect electrical equipment, personnel and structures from electrical faults, lightning strikes and transient overvoltages.

- Industrial and commercial installations – the coupling work in various sectors in the industries such as manufacturing, commercial buildings, hospitals, among others. They help establish proper electrical grounding which complies with safety regulations.

- Lightning protection – coupling connects the lightning protection system to the ground rods and this helps to dissipate the electrical current to the ground.

- Telecommunication – the coupling helps to protect sensitive electronic equipment from electrical surges, static discharge and electromagnetic interference.

Installation process of the ground rod coupling

The installation process of the ground rod coupling varies depending on the type and design of the ground rod coupling to install. It is advisable to follow the manufacturer’s instructions and the local standards. When in doubt, always leave the installation for the experts and professionals in the electrical industry. The following is a basic process of the ground rod coupling.

- Prepare the ends of the ground rods connecting to the coupling and ensure the ends are clean, free from rust, dirt and any other contaminants that hinder electrical connections.

- Insert the coupling onto one of the ground rods and make sure it positions securely and centered on the rods end.

- Insert the second ground rod into the other end of the coupling.

- Secure the coupling by use of appropriate mechanisms. For a threaded coupling, rotate it clockwise until it is tightly threaded onto both rods. For a bolted coupling, align the two halves and fasten them together using the provided nuts and bolts.

- Visually inspect the connection to ensure that installations aligned and are tight.

- Test the grounding system to ensure its effectiveness using appropriate grounding testing equipment to measure resistance.

Selecting the best ground rod

The selection process of the ground coupling depends on the intended use, reputation of the manufacturer and the specific application. It is advisable to consult with professionals and experts n the industry that can provide information and guidance on the best ground rod couplings for your project. There are also some factors to consider for selecting the best coupling which are as discussed below.

- Select a coupling made from a highly conductive and corrosion-resistant materials to ensure good electrical conductivity and long-term durability.

- Consider the specific type of coupling that best suits your application.

- Check for coupling that offer low-resistance connections to ensure efficient dispersion of electrical energy into the ground.

- Evaluate the cost effectiveness of the coupling by considering the initial cost and the maintenance and repair costs.

- Consider the ease of installation and compatibility with your installation methods and components.

- Consider the reputation of the manufacturer who should have a track record of producing high quality ground rod couplings.

- Ensure the coupling meets relevant safety standards and electrical codes in your local area.