An expanding bar is an anchor used to secure transmission lines poles to the ground. This helps to provide a stable foundation for the pole. Expanding bar is mainly useful in situations where traditional anchors are unfeasible due to soil conditions. It has a helical design that allows for screwing into the ground without the need for excavation or hammering. Expanding bars reduce soil disturbance during installation as compared to traditional anchors. It is from durable materials that provide excellent corrosion resistance and long-term durability. These materials include galvanized or hot-dip galvanized steel. the expanding bar anchor offers reliable solutions for securing transmission line poles. Thie helps to provide stability even in diverse soil conditions in South America. Types of expanding bar include ground screws, soil screws, expansion anchors and screw-in anchors. They find use in applications such as transmission line, telecommunication towers, renewable energy installations and streetlights.

Key features of expanding bar

Expanding bars have various features that help to ensure their effectiveness in various applications. Their anchorage depends on their design and functionality. The following are the key features of expanding bars.

- Helical design – this design allows for efficient penetration into the soil contributing to their stability-enhancing properties.

- Secure soil grip – expanding bars help to expand and grip the soil securely to provide stability to structures.

- Structural load-bearing capacity – they expanding bars have the capability to withstand and support specific loads. It also helps to ensure they effectively anchor structures such as utility poles, transmission lines and renewable energy installations.

- Cost effectiveness – their ease of installation, adaptability and long-term stability contributes to their cost effectiveness.

- Ease of removal – expanding bars may have designs for ease of removal especially in temporary applications.

- Resistance to seismic forces – the bars also provide resistance to seismic forces especially in regions prone to earthquakes.

- Adaptability – the adaptability of the expanding bars to various soil conditions ensures their effectiveness in diverse terrains.

- Secure soil grip – this feature provides stability to structures such as transmission line poles to ensure a reliable foundation.

- Corrosion resistance – they are from corrosion resistant materials that offer protection in coastal or humid environments.

Selection and installation of expanding bar

Proper selection of expanding bars helps to ensure optimal performance in various applications. It involves considering several factors including soil analysis, load requirements, environmental conditions, seismic resistance, application needs and costs. The installation process involves several steps to ensure proper functionality and stability. additionally, it is advisable to consult wit industry professionals for guidance whenever in doubt. The following is a general installation process for expanding bars.

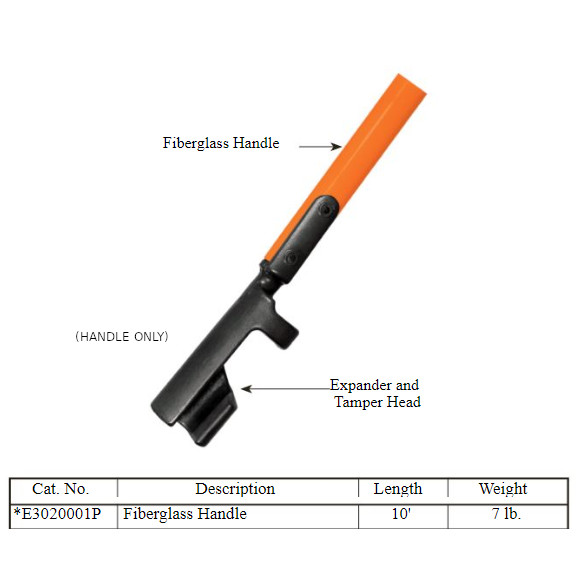

- Preparation – gather all the necessary tools required for the installation. This is including expanding bars, power drill, torque wrench, level and safety equipment.

- Site preparation – clear the installations site of debris, rocks, or any obstacles that may hinder the installation process.

- Drilling holes – use a power drill to create holes in the soil at the desired locations. The depth and size of the holes should match the specifications provided for the expanding bars.

- Expanding bars insertion – insert the expanding bars into the drilled holes in twisting motion to allow the helical design.

- Twisting and expansion – use a torque wrench to twist the expanding bars into the soil and pay attention to the torque applied. This is to ensure it aligns with the manufacturer’s recommendations.

- Alignment check – use a level to check the alignment of the expanding bars and ensure they install vertically and maintain the desired orientation.

- Verifying depth – measure the depth of the installed expanding bars. This helps to confirm the specified depth as required in requirements.

- Torque verification – verify the torque applied during the installation process using the torque wrench. Compare the measured torque with the recommended values provided by the manufacturer.

- Backfilling – backfill the holes with soil to ensure the process does not compromise the stability of the expanding bars.

- Documentation – keep details for the installation including the depth and torque values.

Maintenance and inspection of expanding bar

Regular maintenance and inspection helps to ensure the continued performance and longevity. It also helps to identify signs of wear, corrosion or issues that compromise effectiveness. Additionally, it is advisable to perform regular professional inspections and maintenance for continued reliability. The following is a basic guide for maintenance and inspection of expanding bars.

- Periodically inspect the expanding bars for any signs of damage, corrosion or deformation. Check for changes in color, rust or unusual wear patterns.

- Periodically verify the torque applied during installation and check against the initial torque values. This is to ensure they maintain their intended level of expansion and grip in the soil.

- Measure the depth of the expanding bars to confirm they remain at the specified depth. Changes could impact their stability and load bearing capacity.

- Inspect the surfaces of the expanding bars for rust or corrosion especially in areas with factors like moisture or chemicals.

- Verify the expanding bars meet the load bearing requirements of the anchored structure.

- Clean the expanding bar to remove any accumulated debris, soil or other contaminants. This is to help maintain their functionality.

- Apply corrosion resistant coatings using galvanized expanding bars or implementing other protective measures.

- Consider periodic re-torquing to ensure the expanding bars maintain their intended level of expansion.

- Conduct new soil analysis to help assess the impact on the expanding bars. This is whether any adjustments or extra measures are necessary.

- Refer to the initial installation documentation and compare it with current conditions. Keep all the details of the activity for future reference.

Comparative analysis of expanding bars in South America

Conducting a comparative analysis involves considering the various types, designs and brands of the expending bars. It also includes assessing factors that influence their performance and usage in the region. Additionally, it helps to ensure proper selection of the anchors to meet specific needs of the application. The following are the factors to include in a comparative analysis in South America.

- Soil conditions – assess the various soil types in south America where the expanding bar will install. These include sandy, clay and rocky soils.

- Environmental factors – assess the various conditions that may influence the usability. These include high humidity, coastal areas and potential exposure to corrosive elements.

- Seismic activity – evaluate the presence and effects of seismic activities in the region. Select the expanding bars that have designs for seismic resistance to certain regions.

- Technological advancements – assess the adoption of advanced technologies in construction and infrastructure projects. the bars should have innovative designs that enhance performance in various conditions.

- Economic factors – evaluate the various challenges facing the adoption of the expanding bars. The selected bars should provide cost effectiveness and long-term durability.

Certifications and standards in South America

There are various standards and certifications that govern the use of expanding bars in South America. Some of the South American countries adopt to the international standards for expanding bars. Also, it is advisable to ensure the selected expanding bar meets the relevant standards and certifications. The following are the certifications and standards in south America for use of expanding bars.

- ISO certification – these are international standards that offer guidelines on quality management and ensures the reliability of the anchors.

- ASTM standards – these are standards relevant to construction and geotechnical engineering for bars. They provide guidelines for materials, testing methods and performance characteristics.

- Geotechnical engineering standards – this provides guidelines for the design and use.

- Corrosion resistance standards – these includes certifications for coatings.. It also includes the use of corrosion resistant materials.

Regional market for expanding bars in South America

There are various factors that influence the regional demand and supply of expanding bars in south America. These include market trends, types, manufacturers and suppliers among others. They also include economic conditions, infrastructure projects and other factors. Additionally, it is advisable to observe the market dynamics for guaranteed success. The following are the factors that shape the regional market for expanding bars in South America.

- Economic volatility – economic fluctuations impact the construction activities. This also affects demand for construction materials.

- Competition – the availability of manufacturers and suppliers in the region influence the demand for the bars.

- Urbanization trends – this drives the need for stable structures including utility poles, communication towers.

- Technological advances – this includes innovation in methods and materials which influence market preferences.

- Seismic considerations – the increase in demand for expanding bars designed to withstand seismic activities influence the market.

Frequently asked questions

Expanding bars help to anchor structures such as transmission line poles, utility poles and communication towers. This helps to provide stability in diverse soil conditions.

Regular inspections help to ensure the ongoing stability of structures. This depends on factors such as soil conditions, environmental exposure and project specifications.

Installation requirements may include drilling depth, torque specifications and alignment considerations. Always follow the manufacturers guidelines for safety.