One unique item utilized in electrical power distribution systems is the insulated piercing clamp. It contributes to offering a dependable and safe way to test or tap into high-voltage cables. This is all the while preserving weatherproofing and electrical insulation. It has an insulated housing composed of sturdy polymer components. Electricity insulation in the housing keeps erroneous contact with live components at bay. Additionally, piercing blade penetrates the overhead transmission line’s outer insulation. The blade is mainly located at the core of the device. To keep the clamp in place, it also features a clamping mechanism. For a range of applications, an insulated piercing clamp offers trustworthy electrical connection points. For actions like tapping into the line for extra distribution, this link is helpful. Typical IPC types include bolted, wedge-based and compression insulated clamp.

Financial aspects of an insulated piercing clamp

The price of insulated piercing clamps varies according to some criteria. To choose the solution that best fits the project’s needs in terms of cost, it is necessary to verify these factors. This is to guarantee the performance, quality and financial plan. Prices vary based on voltage ratings and range from $1 to $100. These consist of IPCs with low, medium and high voltages. This facilitates the process of making a well-informed budget-conscious selection. The following variables affect how much insulated piercing clamps cost.

- Manufacturer and brand: the market’s various manufacturers contribute to price variation and trademarks. Certain brands that are mostly known for their dependability and quality come at a higher cost.

- Dimensions and capacity: the IPCs are available in many sizes to accommodate varying voltage ratings and conductor diameters. Higher voltage-rated, larger clamps are more expensive than smaller clamps.

- Quantity discounts: volume and bulk discounts are from purchasing IPCs in greater numbers. This is useful for tasks that call for a large number of clamps.

- Warranty and support: the clamp’s value depends the manufacturer’s availability of warranties and customer help.

- Material and construction: the prices also vary depending on the materials that go into making the clamp. The initial cost of clamps made of premium materials, such as stainless steel, may be greater. They also offer better durability and longevity and reduce the maintenance expenses.

- Features and accessories: the extra features that some clamps have can have an impact on the price. The cost of clamps with adjustable clamping mechanisms may be more than that of simpler types.

- Shipping and handling: think about the costs associated with shipping and handling. This is particularly true when buying clamps from vendors in various places.

Details about the seller and supplier of the insulated piercing clamps

It can be time-consuming to choose the best source of insulated piercing clamps. This is a result of the wide range of producers and suppliers offering a variety of goods on the market. Seeking opinions from industry professionals in electrical matters is also helpful. Ask about the features, cost, least order quantities, delivery choices and any relevant warranties for the product. The general methods listed below help to locate vendors and providers of IPCs.

- Distribution networks: get in touch with local distributors of electrical equipment. This is a result of the large selection of goods they stock from different manufacturers. They also offer details on the insulated piercing clamps that they have in stock.

- Online supplier directories: look for websites like Global Sources, Alibaba and ThomasNet. These platforms let you find specific products and get in touch with vendors all around the world.

- Online markets: look through sites like Amazon, eBay or other marketplaces for electrical equipment.

- Manufacturers of electrical equipment: get in touch with those who have a solid track record. ABB, Siemens, TTF Power, and Eaton are a few of them.They might manufacture insulated piercing clamps themselves, or they might collaborate with vendors who do.

- Trade shows: attend trade events, exhibitions and conferences about the distribution of electrical power. Exhibitors present their newest items, such as insulated piercing clamps, during the events.

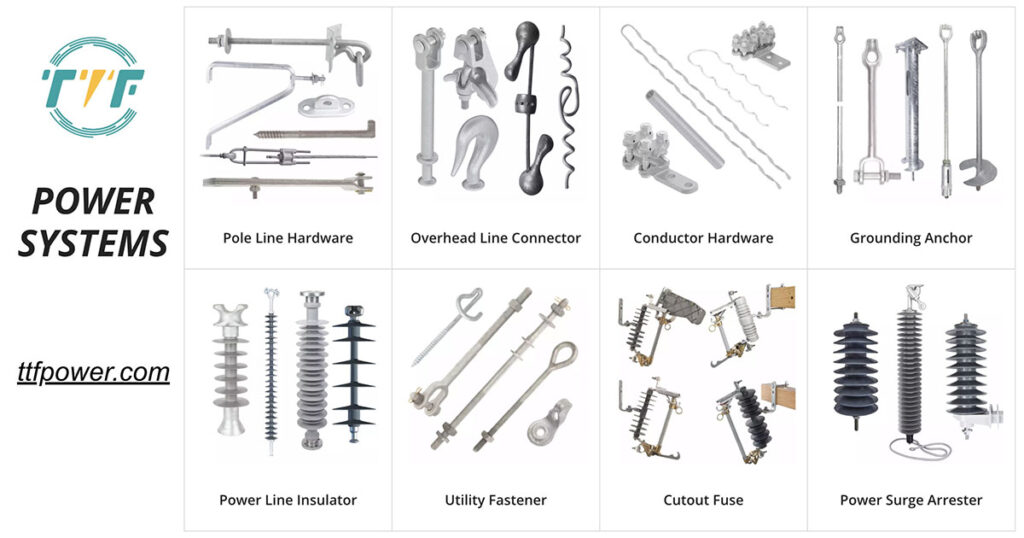

Power line hardware and ADSS/OPGW accessories are available at TTF Power Systems. They provide the widest selection of goods available in the market. This is including insulated piercing clamps. They offer flexible OEM services, a skilled engineering team, and automated production lines. Because of this, they are able to offer solutions that are both affordable and meet industry standards for quality. Their contact details are as follows.

Landline (M-F, 9 am-6 pm): (+86) 22-8523-3528

WhatsApp: (+86) 155-1086-4645

Cell Phone: (+86) 155-1086-4645

Customer Service: support@ttfpower.com

Developments in the insulated piercing connector industry

There have been several developments and breakthroughs in the insulated piercing clamps industry. These developments enhance electricity distribution systems’ performance, safety and efficiency. Making an informed choice on the best insulated piercing clamp is easier when you are aware of these developments and trends. It also aids in your comprehension of how overhead transmission lines are changing. The several developments in the insulated piercing clamp market are as listed below.

- Insulation: advanced and improved insulating materials continue to develop for IPCs. Their resilience to environmental conditions and dielectric strength improves. These elements include pollution, dampness and UV radiation. These components guarantee dependable electrical insulation and help the clamp last longer.

- Better weatherproofing: Producers concentrated on making insulated piercing clamps more weatherproof. This is to survive severe weather, such as strong winds and sudden changes in temperature. In outdoor applications, advanced weatherproofing guarantees dependable operation.

- Remote monitoring and control: the incorporation of IoT technology facilitates remote monitoring. Wireless communication modules that allow for remote access to monitoring data are also included in the clamps. For added convenience, it also enables remote operation, configuration changes, and diagnostics.

- Integrated monitoring and diagnostics: A few contemporary IPCs come equipped with these functionalities. They make it possible to track electrical factors including temperature, voltage, and current in real time.

- Designs that are adaptable and versatile: It’s common to see IPCs with these kinds of designs. They are compatible with both insulated cables and bare conductors. They also have modular components and changeable clamping mechanisms.

- Better installation designs: IPC installation methods and equipment have advanced. They guarantee correct attachment to transmission lines and hurry the installation process. These consist of uniform installation protocols, training courses for installers and specialized installation tools.

Interactions and community forums for insulated connectors

Insulated piercing clamps have many community forums and interactions. Insulated piercing clamp forums are less prevalent. These experts in the field converse and exchange knowledge about the IPCs. Meaningful conversations are also facilitated by sharing experiences, offering insightful commentary and posing questions. Respecting professional norms and community guidelines is also advised. The community forums and typical exchanges on insulated piercing clamps are as listed below.

- Online forums: these focus on electrical engineering subjects are also known as electrical engineering platforms. They also feature portions where experts talk about different parts that work in power systems.

- Electrical Associations: these includes (IEEE) and CIGRE. They offer forums where participants can talk about complex power system-related issues.

- Online comunities: these are for utility workers, lineman or electrical technicians. They also have forums where people discuss insulated piercing clamps.

- LinkedIn Groups: there are a lot of professional groups here that deal with power distribution, utility infrastructure and electrical engineering. They offer perspectives and chances to network with professionals in the field.

- Manufacturer forums: these are online discussion areas where users may exchange stories, pose questions and talk about best practices. These also have to do with how the insulated piercing clamps are mainly used and installed.

- Industry publications and blogs: these include articles, blogposts or forums where professionals discuss various components. This is including insulated piercing clamps.

Using insulated piercing clamps safely

Insulated piercing clamp work in high-voltage electrical systems. As such, using safety precautions and protocols is necessary. This is to guarantee that insulated piercing clamps install safely. These are the insulated piercing clamp safety guidelines.

- Wear appropriate personal protection equipment (PPE) at all times, such as clothes, safety glasses and gloves.

- Before using, check the IPC for any indications of wear or damage. Examine the parts for rust, fractures and other flaws.

- Installing insulated piercing clamps correctly requires adhering to the manufacturer’s instructions.

- Keep a safe distance away from live wires and steer clear of unintentional contact with energized parts.

- Steer clear of operating during storms or other unfavorable weather that could raise the possibility of electrical risks.

- To find and fix any problems, plan on doing routine checks and maintenance on insulated piercing clamps

Frequently Asked Questions

Have an emergency response plan, work in teams, avoid contact with live conductors and wear the proper PPE. Also, inspect equipment for damage and de-energize the lineduring work. Perform routine maintenance and inspections of the insulated piercing clamp.

The advancements include improved weatherproofing, upgraded insulating materials, integrated monitoring and diagnostics features. They also include adaptable and versatile designs, remote monitoring and control capabilities.

The best practices involve adhering to installation instructions and manufacturer guidelines. I also includes making sure overhead transmission lines are properly aligned and attached.