Eye nuts are types of a fastener with a loop at one end which allows it to work as an anchor point. It allows for easy and secure attachment of the load to lifting equipment. It also provides a stable and reliable connection during lifting. An eye nut is from materials such as steel, stainless steel or brass. These materials help to provide strength and durability. It mainly works in applications such as rigging and lifting.

Components of an eye nut

An eye nut has various components working together to ensure the safe and reliable connections. The specific components vary depending on the type and design of the eye nut. The main components of an eye nut are as discussed below.

- Loop – this is the oval-shaped loop at one end of the eye nut that serves as the attachment point for ropes, cables, hooks or other threaded fasteners.

- Body – this is the threaded part that allows it to screw onto a bolt to match standard bolt sizes.

- Threaded shank – this is the part with the helical ridges that allow it to screw onto a compatible bolt.

- Base plate – the base plate is at the sides of the loop that provides extra support and stability when attached to the surface.

Types of eye nuts

There are several types of an eye nut used for the overhead transmission lines and systems. Each type of the eye nut has a designed for specific application and load capacities. Adittionally, the specific type of the eye nut should meet the necessary safety standards and load ratings. The following are the common types of the eye nut.

- Stainless steel eye nut – these eye nuts provide excellent corrosion resistance. This factor makes them ideal for the outdoor applications.

- Swivel eye nut – these nuts have a swiveling mechanisms that allows the eyelet to rotate independently from the threaded shank.

- Ring eye nut – this has a larger, thicker, eyelet in the shape of a ring to offer more specious attachment point for larger ropes and chains.

- Rotating eye nut – these have a design that rotates to allow for the attached load to rotate freely.

- Collar eye nut – a collar eye nut features a collar or flange that provides additional support and stability when the eye nut attaches to the surface.

- Metric eye nut – these nuts match the metric thread sizes to offer compatibility with metric bolts o threaded rods.

- Welded eye nut – welded eye nuts have a welded loop that provides a permanent attachment point. They work in applications where a secure and non-removable connection is necessary.

- Lifting eye nut – lifting eye nuts mainly work in heavy lifting applications and have higher load capacities for industrial settings.

- Shoulder eye nut – a shoulder eye nut has an extended portion between the eyelet and the threaded shank. This provides a larger bearing surface useful for distributing loads and reducing stress on the attachment point.

- Regular eye nut – this is the standard type of eye nut with a circular loop at one end and a threaded shank for attachment to bolts. Also, it is mainly used for general lifting and rigging applications.

Applications of an eye nut

Eye nuts find use in applications such as lifting, rigging and securing tasks for ease of use. The selected eye nut should meet the specific application and meet the necessary safety standards and load requirements. Also, the eye nut should ensure the safe and efficient use of eye nuts in various applications. The following are the common application areas of the eye nuts.

- Lifting and rigging – eye nuts help in lifting operations to create attachment points for lifting slings, hooks or chains.

- Marine applications – stainless steel eye nuts for marine rigging help in securing ropes, cables and accessories on boats, yachts and docks.

- Material handling – eye nuts create a secure attachment point for lifting and moving equipment, containers and machinery.

- Theatrical and even rigging – eye nuts work in theatres and event venues to suspend lighting fixtures, audio equipment and scenic elements.

- Mining and heavy machinery – high strength eye nuts help in lifting and securing large machinery and components.

- Automotive industry – eye nuts help in lifting and securing of components during manufacturing and maintenance in the automotive industry.

- Agriculture – eye nuts are also used for hoisting equipment, suspending agricultural tools and creating a secure tie-down point.

- Pole line construction – eye nuts help to secure cables to poles in the construction of pole lines.

- Overhead transmission lines – the eye nuts are also used to connect cables to insulators or other hardware in overhead transmission lines.

Installation guide for eye nuts

The installation process of eye nuts involves securely attaching them to a surface to create a reliable anchor point for lifting, rigging or securing operations. The process may vary depending on the specific application and the type of eye nut used. Additionally, it is advisable to follow the manufacturers installation instructions for the specific eye nut used. Also, you should consult industry experts for installation guidance whenever in doubt. The installation process is as follows.

- Determine the suitable location for installing the eye nut and ensure the surface can support the intended load.

- Ensure the surface is clean and free of any debris that could interfere with the installation and performance.

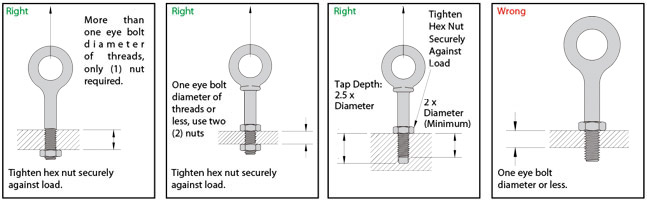

- Screw the eye nut onto the threaded rod or bolt with the matching thread size. Tighten it using hand until the eye nut is comfortable against the surface.

- Add washers or nuts to the threaded rod to create the desired spacing or support to help distribute the load more evenly.

- Ensure the eye of the eye nut positions in the desired directions for proper installations.

- Tighten the eye nut onto the threaded rod and apply even pressure to achieve a secure and stable connection.

- Conduct a test to ensure that the eye nut is securely attached to withstand the expected load.

- Inspect the installation to ensure the eye nu remains in good condition and meet safety standards.

Selecting the best eye nut for your application

There are various types and designs of the eye nut available in the industry to select from. Adittionally, the best eye nut should ensure safety, reliability and optimal performance for your application. There are several factors to consider before the selection process of the eye nut. These factors are as follows.

- Consider the overall cost of the eye nut by balancing quality and performance of the eye nut with your budget constraints.

- Consider the aesthetic aspects of the finished product or application.

- Ensure the eye nut meets the relevant safety standards ad specifications by looking for certifications or ratings from recognized organizations.

- Evaluate the installation process for the selected eye nut and ensure it aligns with your installation capabilities and equipment.

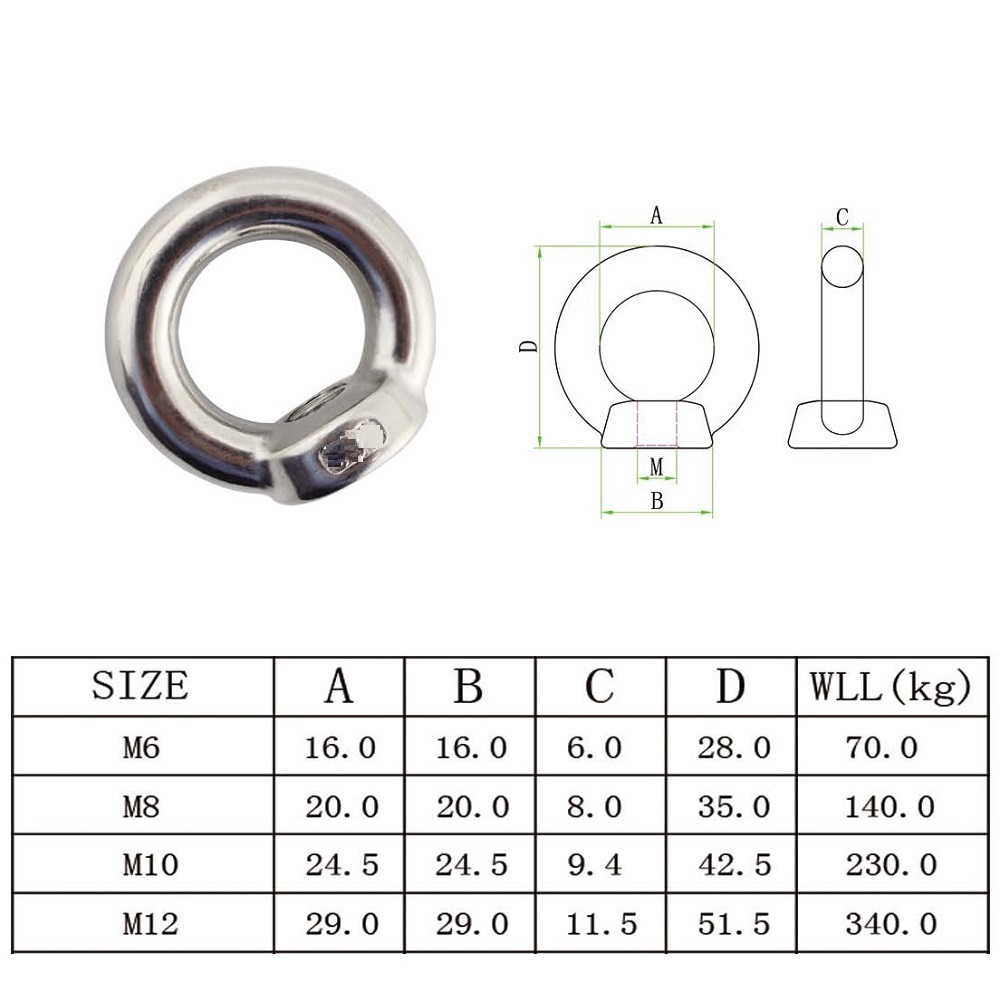

- Determine the maximum load capacity the eye nut expects to support and choose the eye nut with the load rating exceeding the intended load.

- Ensure that the eye nut’s thread size matches the threaded rod or bolt to use.

- Select the suitable material for the eye nut based on the environmental conditions and application.

- Consider the specific design and type of eye nut that best suits your application which includes the eye nut, collar eye nut, shoulder eye nut or swivel eye nut.

- Select eye nuts from reputable manufacturer known for producing high-quality and reliable products.