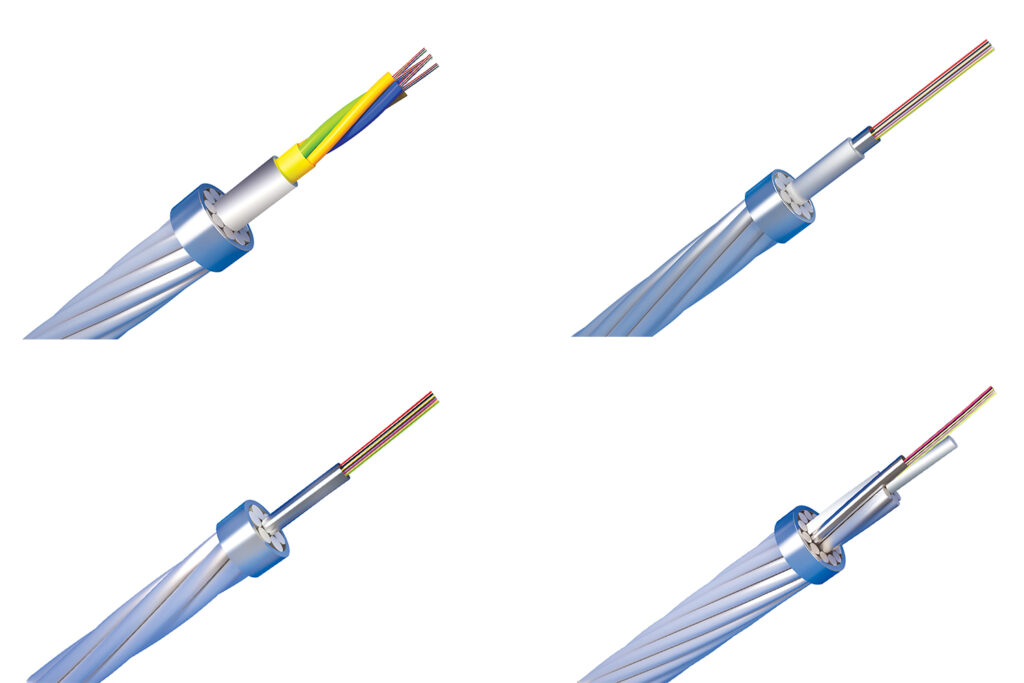

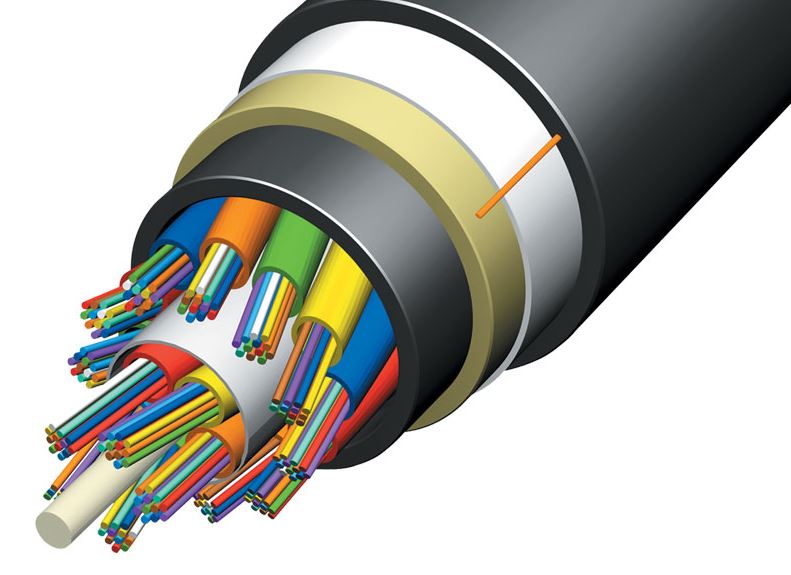

ADSS, OPGW and OPPC accessories are different types of fiber optic cables used to transmit electricity or communication signals. All Dielectric self-supporting (ADSS) does not need any metallic conductor for support. The optical fibers inside ADSS cables help in data communication. This includes telecommunication or internet services. They work with suspension clamps, tension clamps, vibration dampers and dead-ends. Optical Ground Wire (OPGW) acts as both ground wire for electrical protection and communication medium for data transmission. They work with accessories such as ground wire grips, optical fiber splice closures and preformed line products. Optical phase conductors (OPPC) integrate optical fibers into the conductive phase conductors themselves. It combines the functions of traditional conductors with communication capabilities. They work with accessories such as suspension clamps, dampers and spacers.

Components of ADSS, OPGW and OPPC accessories

The components of these cables play a vital role in their installation, support and protection. The components vary depending on the manufacturer, cable design and application requirements. These accessories help in the installation, functioning and longevity of ADSS, OPGE and OPPC cables. They also help ensure reliable and efficient performance of overhead transmission lines. The following are the components of ADSS, OPGW and OPPC cables.

ADSS

- Suspension clamps – these helps to suspend the ADSS cables from supporting structures.

- Tension clamps – they provide support and maintain tension along the length of the ADSS cable.

- Vibration dampers – these reduce the vibration of ADSS cable caused by winds.

- Dead-ends – dead-ends help secure the ADSS cable to the end oof the transmission line.

- Helical fittings – these helps connect the ADSS cable to the supporting structure.

OPGW

- Ground wire grips – they connect the OPGW cable to the supporting structures.

- Optical fiber splice closures – they protect the joints between the different sections of the optical fibers.

- Preformed line products – protect and support the OPGW cable on transmission towers.

OPPC

- Conductor accessories – OPPC cables use accessories such as suspension clamps, spacers and dampers. They help to maintain the conductor’s position and function.

- Optical fiber splice closures – these protect the splices or joints between different sections of optical fibers within the OPPC cable.

Types of ADSS, OPGW and OPPC components

ADSS, OPGW and OPPC accessories enhance performance, reliability and safety. The specific designs and types vary depending on the cable manufacturer, regional standards and installation requirements. The accessories also ensure proper installation, support and protection of these types of cables. The following are the common types of the accessories.

- Suspension clamps – suspension clamps help to suspend the ADSS cable from supporting structures. They have designs such as wedge-type, yoke-type and armor grip suspension clamps.

- Tension clamps – tension clamps provide support and maintain proper tension along the length of the ADSS cable.

- Vibration damper – the dampers reduce vibration and oscillation of the ADSS cable. This helps to prevent fatigue damage and ensure durability.

- Dead-ends – these help to anchor and secure the ADSS cable at the endpoints of the transmission line. They maintain tension and prevent sagging.

- Ground wire grips – these help to connect the OPGW cable to the supporting structure and provide electrical grounding.

- Optical fiber splice closures – splice closures protect the joints between different sections of optical fibers within the OPGW cable.

- Conductor accessories – these include suspension clamps, spacers, dampers and helical fittings. They help maintain the position and function of the conductor.

- Optical fiber splice closures – splice closures protect the splices between the different sections of optical fibers within the OPPC cable.

Applications of ADSS, OPGW and OPPC accessories

The accessories used in ADSS, OPGW and OPPC cables find use in various applications in the industry. The specific applications vary depending on the type of cable, installation requirements and environmental conditions. Additionally, ensure that the accessories provide proper installation and maintenance. This is to increase durability of the transmission lines. The following are the common application areas of the accessories.

- Mechanical support and installation – accessories ensure the cables are properly installed and maintained. This helps to prevent sagging or excessive movement.

- Vibration and sag control – vibration dampers help to control the vibration and oscillation of the cable caused by strong winds. This helps reduce stress and fatigue on the cables to ensure reliable performance.

- Electrical grounding and lightning protection – round wire grips provides electrical grounding for the transmission line. It also offers safe dissipation of electrical currents and prevent damage to the system.

- Strain relief and mechanical protection – preformed line products provide strain relief and mechanical protection for OPGW and OPPC cables. This helps distribute the mechanical forces and prevent damage to the cables.

- Communication and data transmission – the accessories ensure proper installation and support of the optical fibers. This facilitates reliable data transmission for telecommunications or internet services.

Installation of the ADSS, OPGW and OPPC accessories

The installation of the accessory should ensure proper functioning and longevity of overhead lines. The installation procedure varies depending on type of accessory and manufacturer’s guidelines. Additionally, seek advice from industry experts on the installation whenever in doubt. The following is the basic procedure of ADSS, OPGW and OPPC accessories.

- Ensure you have all the necessary tools and equipment to use and that they are in good condition.

- Identify the suitable installation location and securely attach the clamps. Place the ADSS, OPGW and OPPC cables into the clamps and fasten them securely.

- Install the vibration dampers at desired locations and ensure they are correctly positioned and tightened to reduce vibration.

- Place the helical fittings at the endpoints to connect the cables to the supporting structures.

- Install fiber optic splice closures to the OPGW and OPPC cables. This is to protect the joints between the different sections of optical fibers.

- Install ground wire grips at suitable points to connect the cable to the supporting structures.

- Conduct and inspection to ensure they are all properly and securely connected. Perform any necessary testing to verify the integrity of the system.

Selecting the best accessories

The selection process of such accessories may be a tough nut to crack since there are various types and designs in the industry. Selecting the right accessory ensures reliable and efficient performance of overhead transmission lines. Additionally, consulting with industry professionals help with valuable insights when selecting the accessories. The following are the key factors to consider when selecting the best accessories.

- Consider the cost and budget constraints of the selected accessory and balance the cost with the quality and performance.

- Choose accessories that are easy to install and have clear installation guidelines. This helps to provide proper and efficient installation.

- Ensure the accessories selected are compatible with the specific type of cable to use.

- Consider the environmental conditions such as temperature variations, humidity, corrosion potential and exposure to UV radiation.

- Select accessories that offer effective vibration dampening to reduce cable oscillation.

- Select accessories from manufacturers that provide reliable technical support. This includes other reasonable warranties for their products.

- Consider the quality and design of fiber optic splice closures. This is to protect the optical fibers from environmental elements.

- Evaluate the load capacity of the accessories and ensure they have a suitable safety factor to handle the maximum expected loads.

- Ensure the accessories follow relevant international and regional standards.

- Assess the accessories durability and expected maintenance requirements. The accessory should require less replacements and reduce maintenance costs.