A pole band is also a metal band used to secure various components to utility poles. It is also known as pole strap or pole banding. They secure items such as electrical boxes, transformers or fixtures to utility poles that need to be firmly mounted to the pole. Pole bands provide a tight and secure grip on the pole and ensure the attached components remain in place under load or other forces. Pole bands are from durable materials such as galvanized steel or other sturdy materials to provide strength and durability. Pole band wraps around the pole and fasten securely using fasteners such as bolts, nuts and washers among others. They find use in power lines, communication equipment, traffic signs, security cameras, banners and construction.

Components of pole bands

A pole band consists of various components that work together to provide a secure and reliable attachment system for various equipment. They have various designs particularly to meet the specific requirements of the applications. the available components also vary depending on types, design, size and application of the pole band. The following are the main components of a pole band.

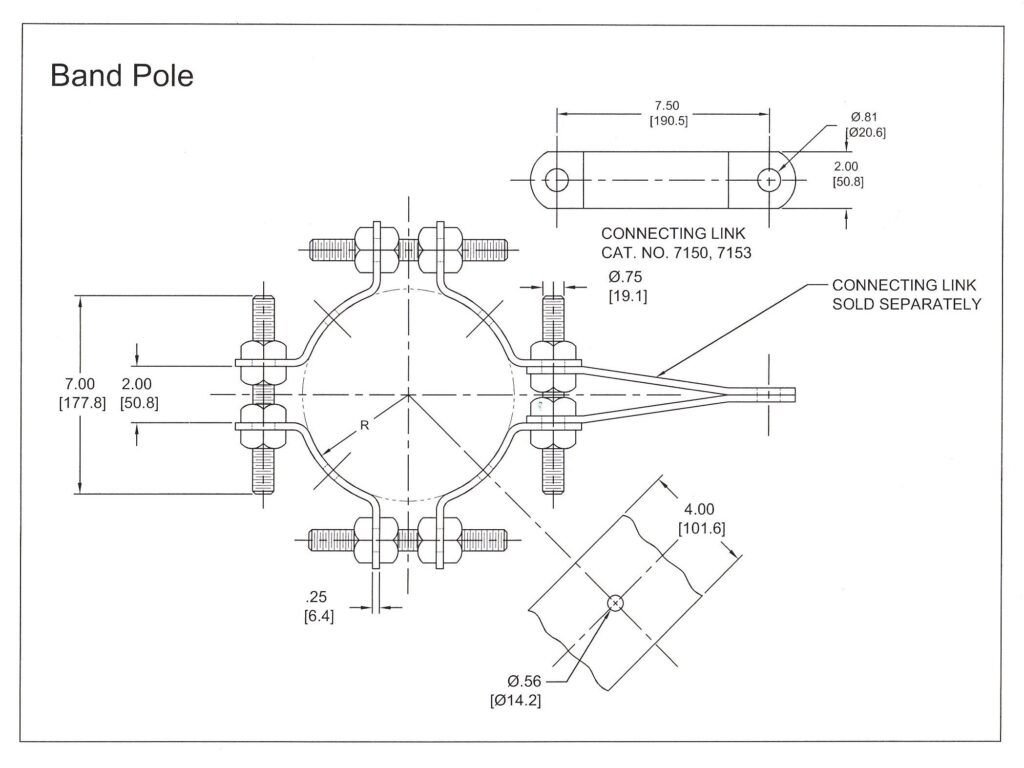

- Band – this is the main part of the pole band that wraps around the utility pole or cylindrical structure designed to provide a secure grip on the pole. This helps to hold the attached components in place and prevent loose connections.

- Holes – the band has pre-drilled holes along its length that serves as attachment point for fasteners such as bolts, nuts and washers.

- Fasteners – fasteners include bolts, nuts and washers that secure the band around the pole by passing through the holes in the band. This helps to provide necessary tension to hold the band firmly in place.

- Mounting hardware – the pole band includes extra mounting hardware that include brackets with pre-drilled holes to secure specific components to the band.

Types of pole bands for overhead line installations

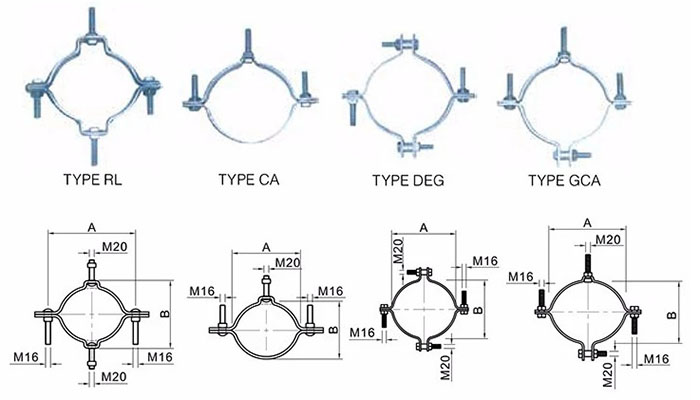

Pole bands are available in different designs and sizes for different applications in the industry. Because of this, selecting the best pole band can be a tricky phase. This is because the type of pole band selected should meet the specific requirements of the application. The type selected also depends on weight and size of equipment to attach. The following are the common types of pole bands.

Standard pole band – this is the most common type of pole band used for general-purpose applications. These include securing electrical boxes, junction boxes, or small equipment to utility poles.

Overhead line hardware pole band – these pole bands help in attaching components such as insulators, crossarms or conductor clamps to utility clamps. The design allows them to handle the specific loads and forces associated with overhead power lines.

Transformer pole band – these help to secure attachment of transformers to utility poles. They are larger and stronger than standard pole bands.

Adjustable pole band – these pole bands allow adjustment in size and diameter. They are often used in areas that need accommodation of poles of various sizes. They have sliding brackets that can tighten or loose to fit different pole diameters.

Communication equipment pole band – these pole bands secure various communication devices such as antennas, satellite dishes or wireless equipment.

Sign mounting pole band – these secure signs and banners to utility poles to hold them in place to withstand wind loads.

Application of pole bands

Pole bands help to secure various components used in utility poles and provide strength and durability. They find various applications in utility infrastructure, construction and other industries. Their versatility, strength and secure attachment capability make them a valuable component in various industries. The following are the main application areas of pole bands.

- Overhead line hardware – pole bands help in the installation of overhead power lines. This is to attach components such as insulators, crossarms, conductor clamps and vibration dampers.

- Traffic signs and street lights – pole bands help to mount traffic signs, streetlights to utility poles. They ensure the signs and lights remain in position and visible for effective traffic management and safety.

- Banner and sign mounting – pole band help mount banners, signs and advertisements displays to utility poles.

- Electrical equipment attachment – pole bands secure electrical equipment to utility poles such as boxes, junction boxes or meter cabinets.

- Communication equipment – pole bands support installation of communication devices such as antennas, satellite dishes, wireless communication equipment and other infrastructure.

- Security camera installation – they also help mount security cameras and surveillance equipment to utility poles and provide a stable platform for installation of cameras.

- Construction of structures – pole bands help in construction to secure temporary structures. This ensures safety of workers and maintain the integrity of the construction site.

Installation process of pole bands

Installation process of the pole bands should meet all the necessary requirements of the applications. It should also observe the local standards and regulations for electrical installations. Some manufacturers and suppliers offer installations of the product to follow during installation. Additionally, it is important to consult with professionals in the industry for guidance on the best installation procedure to ensure proper installation of the pole band. The following is a basic installation process for the pole bands.

- Prepare the pole before installation and ensure it is clean and free from debris. This could hinder the installation and performance of the pole band.

- Position the pole band on the pre-drilled holes around the pole.

- Insert the fasteners through the pre-drilled holes in the pole band. Ensure they align correctly for tightening.

- Tighten the fasteners using the suitable tools against the pole. Ensure it is not too tight to prevent damaging the pole band.

- Inspect the installation to verify the stability and alignment of the attached equipment. Check for signs f any loose fasteners, misalignment, or other issues.

Selecting the best pole band for overhead power installations

Different types and designs of the pole band meet different specifications of the overhead power systems. The selected pole band should provide the necessary strength, durability and reliability for securing equipment to utility poles. Also, it is advisable to consult with professionals for guidance on the best pole band for your application. Selecting the best pole bands involves considering a variety of factors. These factors are as discussed below.

- Consider the cost of pole band keeping in mind the quality and performance. Compare prices from different manufacturers and suppliers based on their features, durability and overall value.

- Consider the attachment method required for the equipment and check the compatibility of the pole band.

- Select pole bands made from durable materials such as galvanized steel or stainless steel to provide good strength, corrosion resistance and longevity.

- Determine the expected load requirements and select pole band that can handle the weight and stresses associated with specific application.

- Ensure the selected pole band is compatible with the size and diameter of the utility poles to install on. This includes checking band’s width, length and adjustability options.

- Ensure the pole band complies with the relevant industry standards, codes and regulations to ensure compliance with safety requirements.