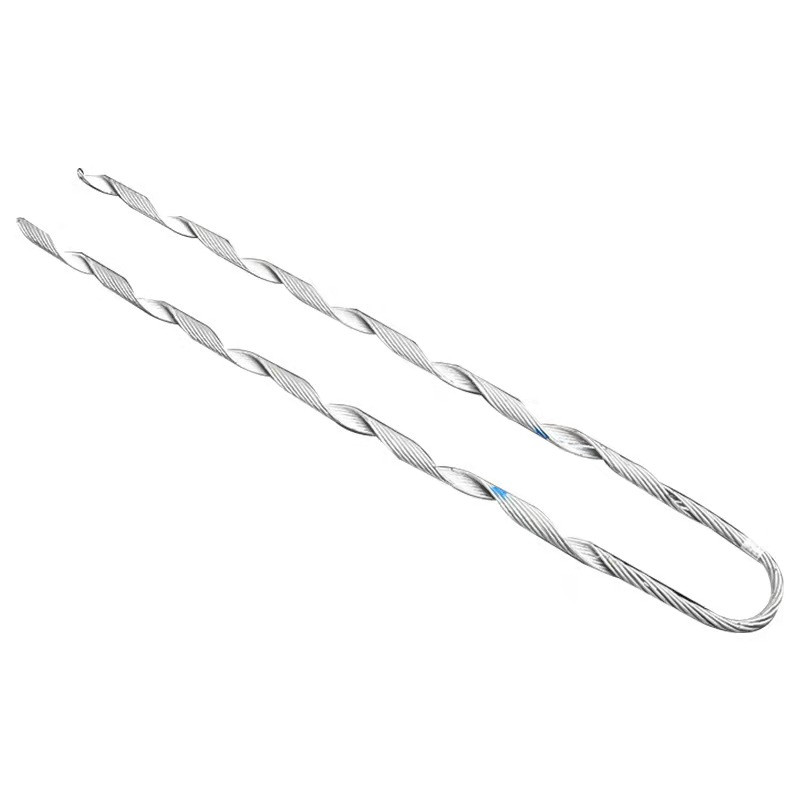

One part used to secure wires to support structures like poles is a preformed tension clamp. Its construction makes it more resistant to weather factors and mechanical pressures. Preformed tension clamps encircle the conductor with one or more gripping devices. To avoid putting too much stress on any one spot, it is helpful to disperse the strain along the conductor’s length. Preformed tension clamps are from sturdy materials like steel, galvanized steel or aluminum alloy. Since it can be install with basic tools or by hand, it also provides simple installation features. Applications for the clamps include distribution networks, electrical installations and telecommunications.

Using preformed tension clamp has advantages

There are several advantages to using preformed tension clamps on overhead transmission lines. The clamps improve the overhead transmission cables’ dependability, efficiency and safety. This is all the while providing affordable options for operating and maintaining infrastructure. The advantages of preformed tension clamps for many applications are as follows.

- Performance – the preformed shape of the clamps guarantees consistent performance between installations. This aids in keeping the conductor’s tension levels at the appropriate levels. It also enhances the transmission line’s dependability.

- Increased security – conductor sliding is less likely thanks to prefabricated tension clamps. There may be safety risks as a result.

- Cost-effectiveness – the clamps are cheap because they need less money for installation, maintenance and replacement.

- Environmental resistance – the clamps are from materials that withstand environmental factors. These consist of temperature fluctuations, UV rays and corrosion. This is to guarantee dependable operation in challenging environmental circumstances.

- Easy installation – the clamps have simple installation designs that need less labor and tools. It may aid in cutting expenses and installation time.

- Lower maintenance – preformed tension clamps are from sturdy materials that need less maintenance.

- Versatility – to suit varied conductor kinds and sizes, they are also offered in a variety of styles and sizes. Because of this, they can work in a variety of overhead transmission line applications.

Materials of the preformed tension clamp

Preformed tension clamps are from materials that are robust, long-lasting and resistant to the elements. Preformed tension clamp material selection depends on a number of variables. These mostly consist of performance attributes and environmental factors. It’s also critical to seek expert advice on the appropriate materials for your application requirements. The preformed tension clamps are from the following materials.

- Aluminum alloy – this is a lightweight, highly resistant to corrosion material with a high strength-to-weight ratio. Aluminum alloy clamps can withstand mechanical strains.

- Stainless steel – this is a sturdy and corrosion-resistant material. Because of this, it can work with preformed tension clamps for outdoor use. The reason the material costs more than other materials is because of its performance.

- Bronze – these materials have strong electrical conductivity, mechanical strength and resistance to corrosion.

- Galvanized steel – this is a common material for preformed tension clamps. The zinc coatings on the steel improve its resistance to corrosion. The preformed tension clamp is appropriate for outdoor applications because of its material.

- Composite materials – composite materials provide a strong, lightweight substitute for conventional clamps. They also offer superior electrical conductivity, resistance to corrosion and UV protection.

- Other materials – preformed tension clamps can also be from other materials, such copper or brass.

ADSS cable preformed tension clamps

For ADSS (All Dielectric Self-Supporting) cables in transmission lines, preformed tension clamps are effective. ADSS cables are able to withstand their own weight without the need for further help. When fastening ADSS wires to support structures like poles, the clamp is essential. Preformed tension clamps aid in offering dependable support and safe anchoring. Obtaining expert advice about the clamps used for ADSS cables is also essential. The functioning of preformed tension clamps for ADSS cables is as follows.

- Preformed configuration – the clamps come with a preformed shape that matches the ADSS cable’s diameter and profile. To maintain the appropriate tension level, this design makes sure that the grip is constant throughout the cable’s length.

- Weather resistance – materials used to make the ADSS clamp offer exceptional weather resistance. This guarantees that the clamps are resistant to different environmental conditions. This includes variations in temperature, moisture content and UV radiation.

- Compatibility – ADSS cable clamps need to work with the unique specifications of ADSS cable installations. This covers the installation technique, cable diameter and tensile strength.

- Gripping design – to hold the cable in place, ADSS cable clamps have specific gripping components. They offer a dependable grip to resist tension pressures and match the ADSS cable’s profile.

- Installation – the ADSS cable clamps install at predetermined points along the cable’s path at support structures. They fasten to the building and give the cable a secure anchoring point.

- Mechanical strength – the clamps are from materials with the mechanical strength to tolerate tensile forces. To maintain the stability and dependability of the transmission line, this is to stop the cable from slipping off the support structure.

Tension clamp made specifically for OPGW cables

The designs of preformed tension clamps for optical ground wire cables aim to support the unique properties of the wires. Optical fiber cables integrated into transmission line structures are OPGW cables. It assists in fulfilling the dual roles of acting as a ground wire for the electrical conductors and facilitating data transmission. The characteristics and things to keep in mind when using preformed tension clamps with OPGW cables are as follows.

- Protection for the cable – OPGW cable clamps have designs to shield the cable from mechanical stress and abrasion. This involves cushioning the cable with rubber or elastomeric inserts inside the clamp.

- Electrical separation – this is necessary for OPGW cables since they carry optical fibers besides electrical conductors. By doing this, electrical interference between the two systems will reduce. To keep the isolation, they also incorporate insulating components or design elements.

- Installation specifications -OPGW cable clamps should have designs with simple installation in mind. This will guarantee the right clamping force.

- Gripping mechanism – the OPGW cables’ strength members and optical fibers stay in place through clamps intended to do that. This lowers the possibility of damage to the optical fibers while ensuring the cable anchors to the support structures.

- Corrosion resistance – high corrosion resistance materials work in the construction of the cables. Stainless steel, aluminum alloy and galvanized steel are typical materials. They contribute to the clamps’ durability in challenging environmental circumstances.

Tensile strength of a preformed tension clamp

Preformed tension clamps have variable tensile strengths based on some variables. This covers the precise design, the makeup of the material and the intended use. The prefabricated tension clamps’ makers offer ratings and specifications. Testing and engineering standards will determine this. The greatest load that a preformed tension clamp can bear before failing is its tensile strength. The stability and dependability of overhead transmission lines improves by this strength. Tensile strength measures in kilonewtons or pounds, for example. Preformed tension clamps have tensile strength values starting in the region of a few kilonewtons. This is dependent upon variables like the size, configurations, and anticipated mechanical loads of the conductors.

Using tension clamps safely

Maintaining the integrity of the infrastructure and preventing accidents need a strong emphasis on safety. Preformed tension clamps can be safe and effective by adhering to recommended safety guidelines. When handling premade tension clamps, bear in mind the following safety advice.

- Observe manufacturer instructions – pay attention to the manufacturer’s guidelines for the correct handling, installation and upkeep of the clamps. This covers recommended practices, torque requirements and conductor size parameters.

- Inspection – look for any indications of wear, damage or faults on preformed tension clamps. To guarantee the integrity of the clamp and the installation’s safety, replace any broken parts.

- Safe work area – by putting safety precautions in place, you can keep the area surrounding transmission lines secure. These consist of safety cones, caution signs and barricades.

- Safety – wear appropriate protective clothing, such as safety gloves, safety glasses and headgear and use personal protective equipment (PPE). This lessens the chance of getting hurt by electrical hazards, falling objects, or sharp edges.

- Make sure you are applying the right torque while tightening bolts by using certified torque wrenches.

- Work with qualified personnel – learn that qualified individuals are doing the installation and maintenance duties requiring prefabricated tension clamps.

Frequently asked question

Preformed tension clamps are components used fasten conductors or wires to support structures. They help to distribute tension along the conductor and maintain its stability.

Preformed tension clamps are from materials such as aluminum alloy, galvanized steel, stainless steel, composite materials of bronze and brass.

Preformed tension clamps help maintain the structural integrity and reliability of transmission lines by securely anchoring conductors, distributing tension along the conductor, minimizing maintenance needs, and withstanding environmental and mechanical stresses.