Square head machine bolts are types of fasteners used in overhead transmission lines. A square head machine bolt is also known as a square head machine screw or square head bolt. It helps secure various components such as insulators, clamps and hardware fittings. The square head design allows line workers to tighten or loosen the bolts efficiently. They have mechanical strength, durability and ease of use. It also helps prevent the bolt from rotating while tightening the nut. A square head machine bolt is from materials such as carbon steel, stainless steel or alloy materials. These helps to increase strength, corrosion and environmental conditions. The work in applications such as transmission lines, machinery assembly and automotive among others.

Components of the square head machine bolt

The square head machine bolt has various components working together to contribute their ease of use and functionality. These components make the bolt suitable for applications where a strong and secure connection is essential. The following are the components of the square head machine bolt.

- Head – this is the main part of the bolt that provides a large surface area for gripping with a wrench.

- Shank – this is the smooth cylindrical part of the bolt between the head and the threaded part. It helps to increase the structural integrity for the bolt.

- Threads – the threaded part of the bolt starts below the shank and extends to the end of the bolt. These threads ensure the secure fastening into a nut or threaded hole.

- Threaded end – this is the part of the bolt that enters the corresponding nut or threaded hole.

- Pointed end – this is an optional part of the bolt that facilitates easier insertion into a nut.

Types of a square head bolt

The bolts come in various types and designs to meet the specific requirements of the application and environment. Each type depends on factors such as intended application, load requirements and desired aesthetics. The following are the common types of the square head machine bolt.

- Regular square head machine bolt – this is the standard type of square head machine bolt with a square-shaped head and threaded shaft.

- Step square head machine bolt – these bolts have a reduced diameter shank designed to allow flush installations. This provides a smooth surface and prevents potential interference in the assembled components.

- Tap square head machine – these bolts have threads on both ends which makes them suitable for use as studs.

- Square head carriage bolt – these have a rounded head with a square neck under the head to prevent the bolt from rotating during installation.

- Heavy square head machine bolt – the bolts’ design allows them to withstand heavy loads for structural applications.

- Shoulder square head machine bolt – these bolts have a shoulder between the head and the threaded part. This is to provide a precise and fixed seating surface when used with other components.

- Square head lag bolt – these bolts have a coarse thread designed for wood applications to fasten wood to wood or to other materials.

Applications of square head machine bolt

Heavy-duty square head machine bolts find use in several applications. The specific use of a particular bolt depends on factors such as load requirements, environmental conditions, material compatibility and desired aesthetics. Additionally, safety standards enhance secure and reliable operation of the assembled components. The following are the common application areas of the square head bolt.

- Overhead transmission lines – the bolts work in construction and maintenance of transmission lines. They help secure hardware fittings, insulators and clamps.

- Machinery and equipment assembly – these bolts work in the assembly of machinery and equipment. This include manufacturing machinery, industrial machines and heavy equipment.

- Automotive and transportation – the bolts work in various automotive applications such as truck beds, trailers and agricultural machinery.

- Mining and heavy industries – drilling machinery and other heavy industrial applications use the bolts to secure the connections.

- Structural engineering – square head machine bolts help to connect steel beams, columns and other structural elements in buildings, bridges and infrastructure projects.

- Wood construction – square head lag bolts work in wood construction to fasten wood beams, joists and framing member together.

- Railroad track construction – the bolts also help to secure rails and fasten rail components.

Installation guide for square head bolt

The installation of the square head bolt should ensure a secure and reliable connection of the components. The installation should follow the safety standards and regulations in the installation area. Additionally, you should consult with a qualified professional if unsure about the installation. The following is a basic step-by step guide on the installation of the bolt.

- Prepare the work area and ensure all the components and materials required are readily available.

- Position the components that need to fasten together and ensure they fit and align properly.

- Drill the holes that match the diameter and depth of the square head machine bolts if applicable.

- Insert the square head machine bolt into the drilled holes and make sure the threaded end of the bolt engages with the material.

- Place the nuts and washers over the threaded end of the bolt on the opposite side of the head.

- Tighten the bolts by applying the suitable amount of torque to achieve the required clamping force without over tightening.

- Check that the components are properly aligned and securely fit after tightening the bolts.

- Conduct a final inspection to verify the integrity of the installation and that all bolts are properly seated and secured.

Selecting the best square head machine bolt

The selection process of the square head machine bolts includes various factors to consider. The selected bolt should meet the specific requirements of your application. Investing in the right square head bolt contributes to the reliability and longevity of your assembled components and structures. Additionally, it is advisable to consult the industry experts for guidance on the best bolt for your specific application. The following are the key factors to consider during the selection process.

- Consider the cost of the bolt by balancing the cost and quality of the square head machine bolt for long-term reliability.

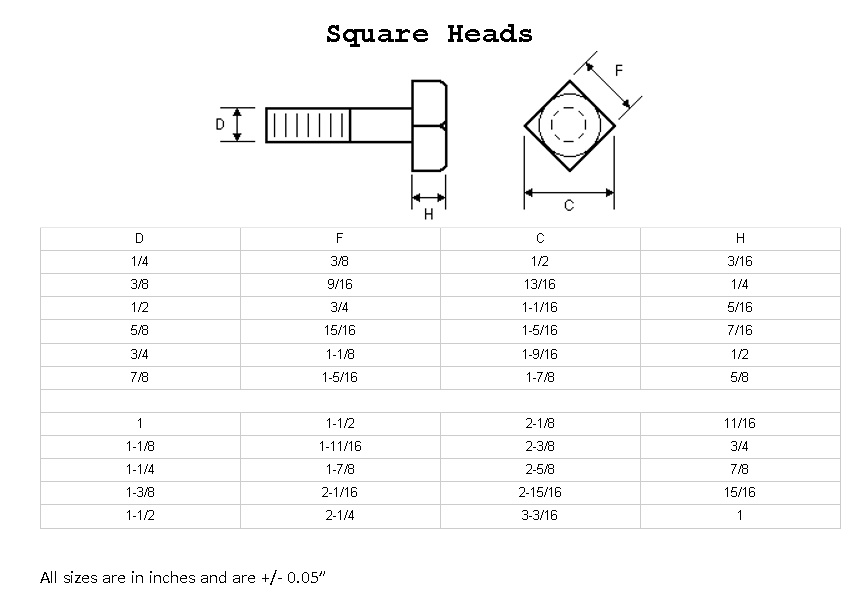

- Determine the appropriate bolt size and length based on the thickness of the materials and required clamping force.

- Evaluate the load capacity requirements of the application and choose the bolt with the right load capacity.

- Choose a square head machine bolt made from materials suitable for your kind of application. Consider factors such as corrosion resistance, strength and environmental conditions.

- Check the thread type to ensure they are compatible with the corresponding nuts or threads for your application.

- Choose the head type that best suits your specific needs such as flush installation or added strength.

- Ensure the square head machine bolt meets the relevant industry of international standards to guarantee their quality and performance.

- Choose the square head machine bolts from reputable manufacturers or suppliers known for producing high quality fasteners.