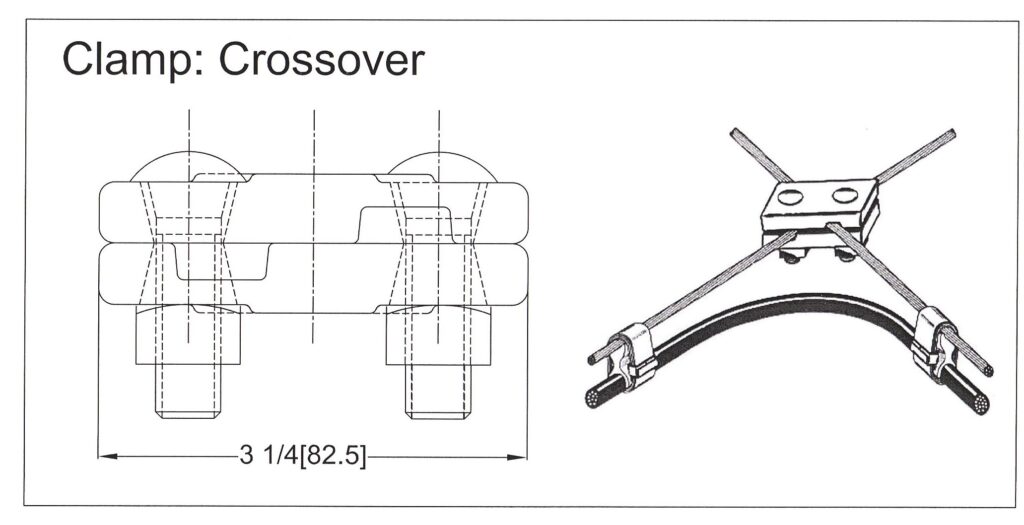

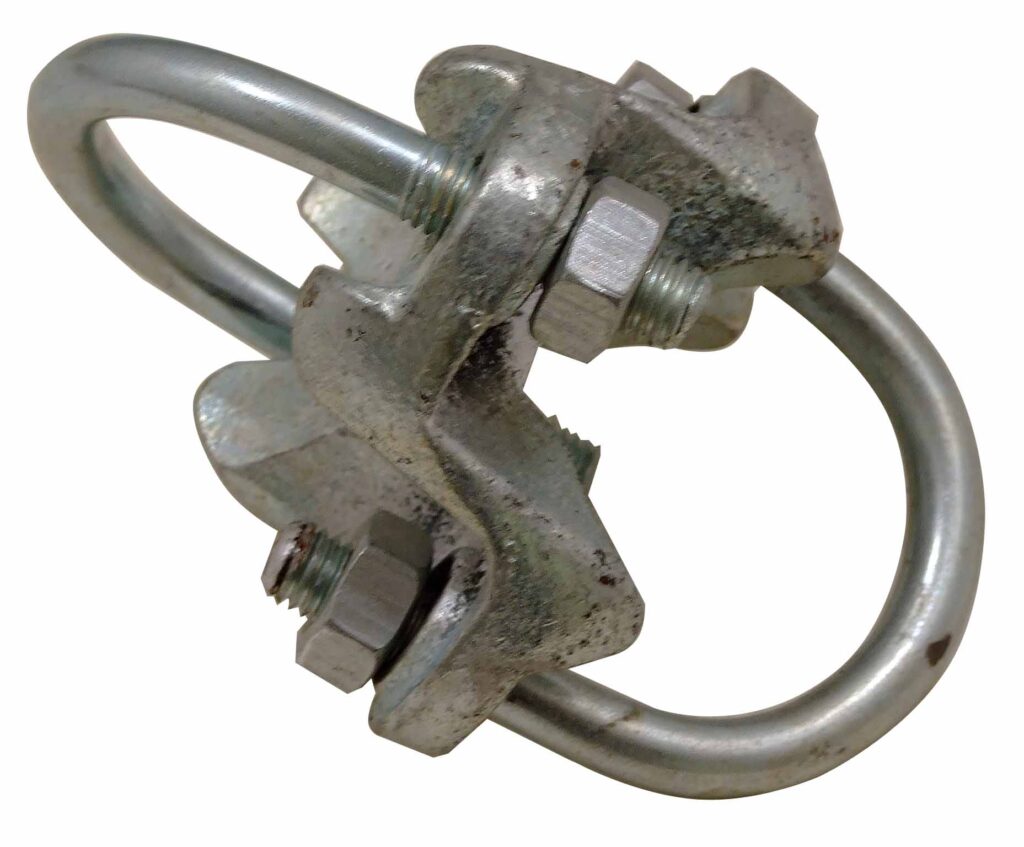

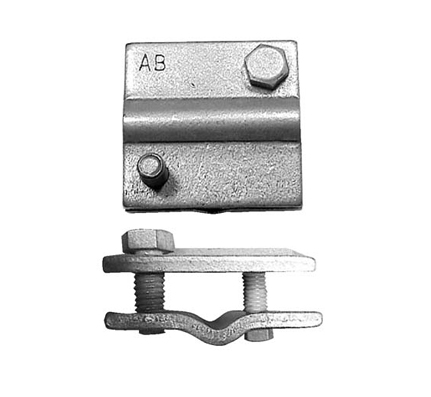

A crossover clamp is a hardware component used to secure and support conductors at crossover points. Crossover clamps maintain the required separation between conductors that cross over each other. This helps to prevent any contact that could lead to electrical faults or short circuits. Their design provides a secure grip on the conductors while ensuring proper spacing. Crossover clamps are from materials that are durable and weather-resistant. These materials include aluminum or steel. they are able to resist the diverse environmental conditions in South America. This helps to maintain the structural integrity and electrical performance of transmission line. Common types include suspension crossover clamps, adjustable , armor rod and parallel groove crossover clamp. They find use in applications like transmission line, maintenance and power distribution networks.

Key features of crossover clamp

Crossover clamps have various features that help to ensure the stability and reliability. The following are the various features of the crossover clamp.

- Corrosion resistance – they are from materials that protect them from the various corrosive elements.

- Ease of installation – they have various designs and mechanisms to streamline the mounting process.

- Armor rod integration – use of armor rods provides extra protection against abrasion and wear. This is to ensure longer service life in challenging conditions.

- Material – crossover clamps are from durable materials like aluminum, steel or alloys. This helps to provide strength and resilience to environmental conditions.

- Adjustability – the clamps have adjustable designs to accommodate different conductor sizes and configurations.

- Mechanical strength – this helps to withstand tension, compression and other stresses in overhead lines.

- Environmental compatibility – consider the environmental impact to make sure the clamps are suitable for diverse climates.

- Fastening mechanisms – the clamps may have designs like bolted or compression-type. This influences the stability and reliability of the clamp.

Selection and installation of crossover clamp

The right selection of the crossover clamp helps to ensure the reliability and safety of overhead transmission lines. It includes considering various features such as conductor type and size, voltage rating, environmental conditions, mechanical strength and costs. The installation of a crossover clamp requires precision and adherence to safety standards. Additionally, it is advisable to seek professional help during installation. The following is a general installation process for the crossover clamp.

- Preparation – gather all the necessary tools required for the installation. This is including crossover clamp, insulating gloves, torque wrench and tensioning equipment. Follow all the suitable safety protocols.

- Installation location – determine the specific location on the transmission line. This is where the crossover clamp will install.

- Work area preparation – clear the work area of any debris that may hinder the installation process.

- Crossover clamp inspection – inspect the crossover for any damage and ensure all components are in good condition.

- Crossover clamp positioning – position the clamp at the desired location on the transmission line.

- Secure crossover clamp – use the suitable wrenches to secure the crossover clamp. Always follow the manufacturer’s torque specifications.

- Adjustment – make any necessary adjustments to accommodate the conductor size and configuration.

- Final inspection – conduct a final inspection to ensure the crossover clamp is securely fastened and components are properly aligned.

- Post-installation checks – monitor the crossover clamp for any signs of movement or wear. It helps to ensure the continued integrity of the transmission line.

- Documentation – maintain detailed records of the installation including the date and location.

Maintenance and inspection of crossover clamp

Regular maintenance and inspection ensures the continued reliability and safety of overhead lines. It also helps to identify and address potential issues that could lead failures and accidents. Regular checks and proactive maintenance contributes to optimal performance of the entire transmission. Additionally, it is advisable to conduct professional maintenance once in a while. The following is a basic guide for maintenance and inspection of crossover clamps in South America.

- Schedule periodic inspection to check for any visible signs of damage, wear or corrosion and loose bolts.

- Check the torque of the bolts securing the crossover clamps to ensure the tight to the manufacturer’s specifications.

- Consider the environmental conditions of the installation site. Ensure the clamp remains corrosion-resistant and performs well.

- Inspect the clamps for cracks, deterioration or any compromise in insulation integrity. Replace any damaged insulation as required.

- Verify the crossover clamp to ensure the clamp remains aligned with the conductors and other components.

- Check the adaptability of the crossover clamp to different conductor sizes. Ensure the adjustment mechanism functions as intended.

- Inspect the clamp for signs of wear, breakage or corrosion and replace them as required.

- Conduct ultrasonic tests to detect potential internal defects or structural issues in the clamp.

- Conduct periodic testing to ensure it can withstand the intended stresses. Always follow the manufacturer guidelines.

- Maintain detailed records of all maintenance and inspection. This is including dates, findings and any actions taken.

Comparative analysis of crossover clamps in South America

Conducting a comparative analysis for crossover clamps involves evaluating the various types and brands. This is dependent on factors such as materials, design, adaptability and performance. The market for crossover clamps is dynamic and it is important to consider the evolving technologies. Also, it is advisable to consult with industry professionals for guidance on the best crossover clamp.

- Material – compare crossover clamps made from different materials such as aluminum, steel or alloys. This is in consideration for durability, corrosion resistance and weight.

- Ease of installation – assess the ease of installation for each type of crossover clamps.

- Adjustability – evaluate the adaptability of crossover clamps to different conductor sizes. This is to offer flexibility in installations with varying conductor configurations.

- Corrosion resistance – examine the corrosion resistance of the clamps especially in areas with diverse climates.

- Mechanical strength – compare the mechanical strength of different crossover clamps. This is especially in areas with high winds or seismic activity.

- Environmental compatibility – consider the performance of the clamps in various environmental conditions.

- Voltage rating – check the voltage rating of the crossover clamps to ensure they align with the requirements of the application.

- Brand reputation – conduct research of various brands offering crossover clamps. They should offer reliability and customer satisfaction.

- Costs – compare the costs of different crossover clamps which should offer durability, performance and features.

- Local conditions – assess how well the clamp adapts to the specific local conditions and challenges in South America.

Certifications and standards in South America

There are various certifications and standards for crossover clamps in south America. They help to ensure the reliability and quality of the clamps in various applications. Some of the south American countries adopt the international standards for crossover clamps. Additionally, it is advisable to ensure the clamp meets the relevant industry standards in the region. The following are the various standards and certifications in South America.

- IEC standards – this provides guidelines for the selection and installation of electrical cable clamps. It ensures the crossover clamps meet international safety and performance standards.

- IEEE standards – this covers the design, testing and performance of hardware used in overhead transmission lines.

- ASTM standards – this develops standards for a wide range of materials, products, systems and services.

- ISO certifications – this is a global standard for quality management systems. It helps to adhere to quality control processes and ensure consistency.

- Local electrical codes – each south American country has their own set of standards for electronics. They help to ensure the safe and legal installations.

- ANSI standards – these are standards related to design and performance of electrical hardware.

Regional market for crossover clamp in South America

There are various factors that influence the regional market for crossover clamps in south America. These factors include types, brands, designs, manufacturers and development. The market may also change due to factors such as economic development, infrastructure projects and industry demands. Additionally, it is advisable to observe the market trends for guidance. The following are the factors that shape the regional market for crossover clamps.

- Renewable energy expansion – the expansion of projects like wind and solar increase the demand for crossover clamps.

- Local manufacturing – availability of local manufacturers and suppliers impact the market in terms of costs.

- Economic factors – economic stability may encourage the increased spending on power transmission and distribution networks.

- Grid expansion – growing cities require the expansion of power grids and increased efficiency. This leads to the increased demand for crossover clamps.

- Infrastructure development – the demand for crossover clamps drives the need for reliable hardware like crossover clamps.

Frequently asked questions

A crossover clamp is a component used to secure and support conductors at crossover points. Its main role is to maintain separation between conductors, prevent electrical faults and increase reliability of the power grid.

Crossover clamps contribute to safety by preventing conductor contact and maintaining the structural integrity of transmission lines. They play a crucial role in reducing the risk of line failures.

Crossover clamps are mainly used in applications such as power transmission, electrified railways and industrial settings.