A big grip dead end refers to a termination point or end point of a cable where a rip secures the cable in place. The “dead end” implies that the cable terminates at the point without further continuation. A big grip is a cable grip designed to handle larger cables. The termination provides stability and support to the cables in areas where the cables faces tension. The big grip dead end has designs to handle the larger diameter and weight of the transmission and telecommunication cables. The dead end also serves to prevent the cable from moving or sagging. Big grip dead ends are from materials like steel, aluminum or galvanized steel. These materials provide a secure hold on the cables and are durable. The big rip dead end also serves in anchoring the ADSS cable to a support structure.

Properties of a big grip dead end

Big grip dead end has properties that ensure the stability, reliability and longevity. They also help the big grip dead end to meet its roles in various applications. These roles include anchoring overhead cables, distributing tension and maintaining their integrity. The following are the properties of a big grip dead end.

- High strength – the big grip dead end is from materials with high tensile strength that withstand tension and stress. These materials include steel and other durable alloys.

- Secure grip – this is the main function of the big grip dead end in several applications. It has designs that wraps around the cables providing a firm grip to prevent slippage.

- Environmental resistance – the big grip dead end is able to withstand exposure to various environmental factors. This is including UV radiation, extreme temperatures and moisture.

- Corrosion resistance – they should be corrosion resistant to withstand varying weather conditions. Coatings and treatments protect them from rust and degradation.

- Compatibility – big grip dead end should have designs compatible with the specific type and diameter of cables used. It should accommodate the size and weight of the cables without causing damage.

- Conductor protection – it should also have designs to protect the conductors of the cables from damage.

- Ease of installation – big grip dead end should also ease easy installation. They may have features such as simple mechanisms for tightening.

Uses and functions of a big grip dead end

Big grip dead end finds use in overhead transmission and telecommunication systems. They help to ensure the stability, reliability and safety of infrastructure. This is by providing anchoring, distribution and stability. The following are the functions of big grip dead ends.

- Cable termination – a big grip dead end terminates overhead cables at the end of their run. This helps prevent cables from continuing further and provides a stable anchor point.

- Tension distribution – they also help distribute tension along the length of the cables. This helps prevent excessive stress on the cables and reduces the risk of damage.

- Cable damage prevention – the secure grip helps prevent cable damage. This may be from movement, vibration or abrasion. It also keeps the cable in position and reduces the risk of wear and tear.

- Maintenance and inspection – big grip dead end eases maintenance and inspection of cables. This is by providing defined termination points.

- Anchoring to structures – the main function of the big grip dead end is to anchor overhead cables. It holds the cables in place and prevents them from sagging or moving.

- Support and stability – big grip dead ends provide support and stability to the system. this helps to maintain the integrity of the infrastructure and ensures uninterrupted transmission.

- Safety – proper installation enhances safety of transmission and telecommunication systems.

- Adaptability – they also have designs to accommodate various types and sizes of cables.

Application areas of big grip dead ends

Big grip dead end find use in various industries and applications where overhead cables need anchoring to structures. The application also varies depending on the functionality, reliability and safety of infrastructure systems. Additionally, it is advisable to seek professional help to understand the uses of the selected big grip dead end. The following are the applications of big grip dead ends.

- Transmission lines – big grip dead ends work in power transmission lines to anchor overhead cable to utility poles. They provide stability and prevent sagging.

- Telecommunication lines – they also secure fiber optic cables, coaxial cables or other lines to poles. They maintain proper tension in the cables and support reliable data transmission.

- Line angle changes – This is in areas where transmission lines change direction or angle to accommodate the variation.

- Wind and solar farms – the dead ends work in renewable energy installations. They help to secure cables connecting turbines to substations or grid interconnection points.

- Railway electrification – big grip dead ends work in railway electrification systems to anchor overhead catenary wires. They provide support and ensure uninterrupted power supply to electric trains.

- Temporary connections – big grip dead end work in temporary connections during construction or maintenance activities.

- Tensioning – they play a crucial role in maintaining proper tension in transmission lines. This is by gripping the conductor and distributing the applied load . This results in prevention of excessive sagging or stretching.

- Aerial fiber optic installations – the dead ends work to terminate and anchor fiber optic cables to poles. They help maintain the integrity of fiber optic network and prevent signal loss.

- Guyed structure – big grip dead ends work in guyed structures where extra support adds to the transmission line using guy wires or cables.

Big grip dead end construction

Construction of a big grip dead end involves several components and processes. It also involves installation to ensure the reliable and secure anchoring of cables. Additionally, it is advisable to consult with experts for guidance on the installation. The following is a detailed explanation of the construction and working of big grip dead ends.

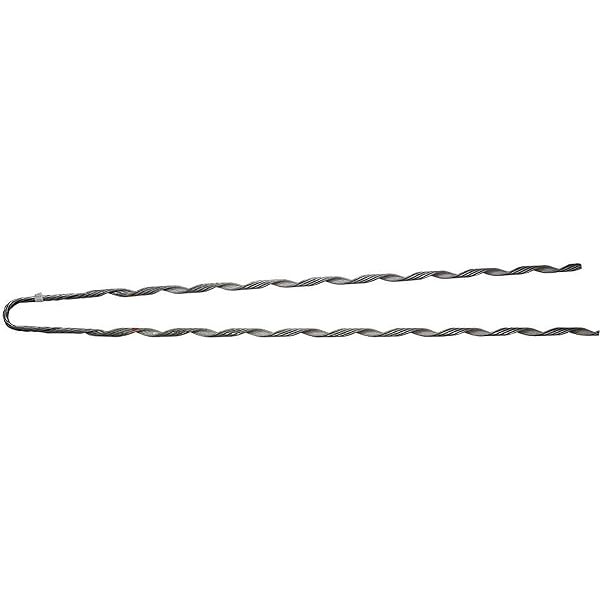

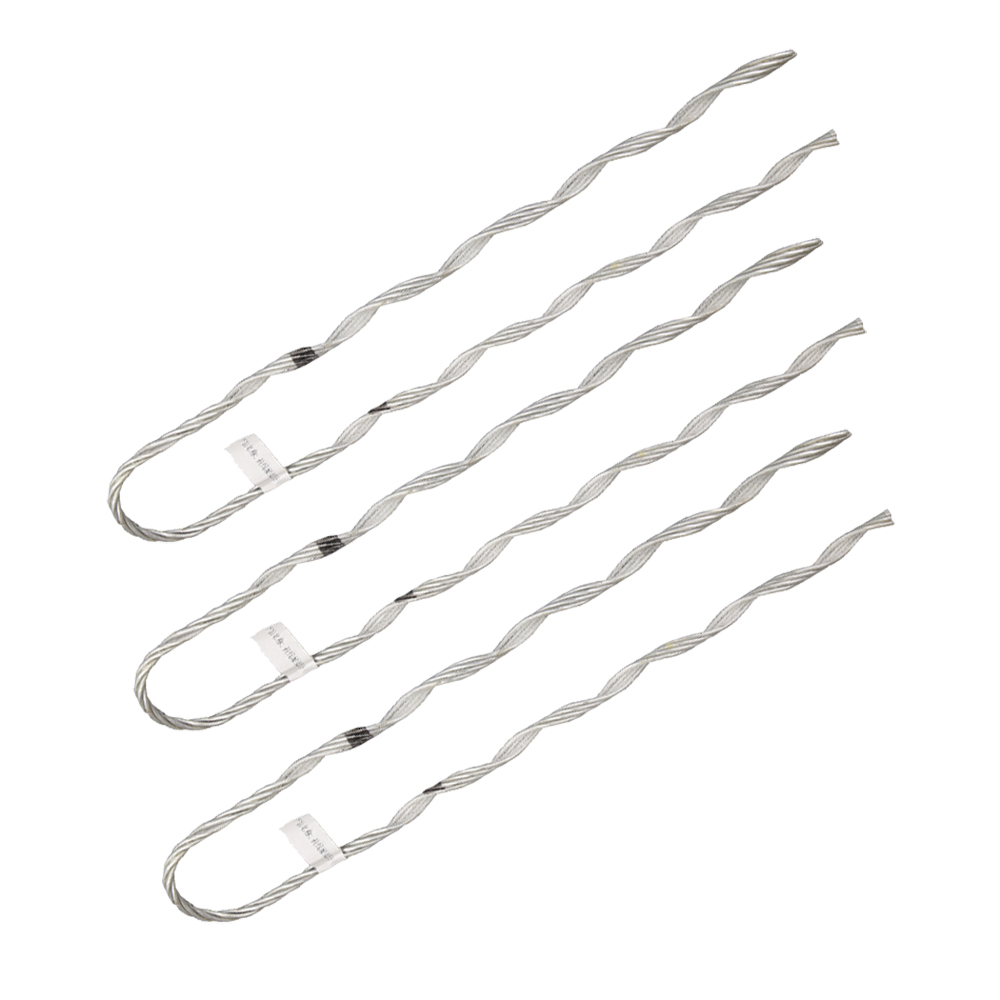

- Big grip assembly – this consists of a grip mechanism designed to hold the cable. It includes a mesh-like structure made of durable materials like steel. it also works with clamps or bolts for tightening around the cable.

- Support structure – this is the utility pole, transmission tower or other structure where the cables anchor. It should be able to support the tension from the cables.

- Attachment to cable – the big grip assembly slides into the end of the cable to ensure positioning for termination. This creates a firm grip on the cable preventing slippage.

- Positioning and anchoring – position the big grip dead end at the desired location for termination. Secure it to the structure using suitable hardware like bolts and brackets.

- Tensioning – apply tension to the cable using tensioning devices to achieve the desired level of tension in the cable. This helps to ensure stability and prevent sagging.

- Trimming excess cable – trim the excess cable protruding from the big grip assembly using cable cutters.

- Inspection – inspect the big grip dead end to ensure all components are securely attached and tensioned.

- Functionality – the big grip dead ends serve to anchor the overhead cables to the support structure. It provides stability and prevents movement or sagging. It also distributes tension along the length of the cable to ensure reliable transmission.

Community forums and interactions for dead ends

Community forums for big grip dead ends can provide discussions and interactions providing more insights. This is including platforms focused in electrical engineering, power transmission, telecommunications and other industries. Active participation in such platforms can help learn from others. The following are the forums with discussions about big grip dead ends.

- Electrical engineering forums – find websites dedicated to electrical engineering where professionals have discussions.

- Telecommunication forums – forums and platforms dedicated to telecommunications professionals have topics related to installation and maintenance.

- LinkedIn groups – join relevant LinkedIn groups related to electrical engineering, power transmission or telecommunications. They provide opportunities to connect with professionals in the industries who share insights on big grip dead ends.

- Professional associations – industry-specific professional associations may have online forums, discussion boards or networking events.

- Power engineering communities – online communities focused in power engineering and utilities may have discussions about installation, maintenance and performance.

- Industry-specific websites – websites focused on the electrical, power, or telecommunication industries may have forums for interactions. Professionals and enthusiasts can interact and exchange information about equipment and components used in the sectors.

Frequently asked questions

A big grip dead end is a specialized termination point used in overhead transmission and telecommunication systems. It securely anchors cables or wires to support structures.

Big grip dead ends work in various industries including power transmission, telecommunications, railway electrification and utility distribution networks.

Benefits include providing stability and support to overhead cables, distributing tension along the length of the cable. It also prevents sagging or movement and ensures the reliability of the infrastructure.

There may be industry-specific standards governing the design, construction and installation of big grip dead ends.