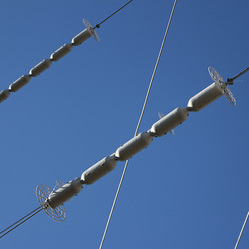

A line guard is a component that protects and maintains the integrity of conductors. A line guard keeps the lines safe from lightning strikes. It protects the conductors from mechanical damage induced by external forces such as wind or galloping. It also helps to dampen aeolian vibration and other dynamic movements. This might cause fatigue and failure of the conductor. Line guards provide protection from external factors such as salt, pollution, and bird contact. This prevents physical damage and lowers vibrations, extending the life of gearbox lines. The use of line guards reduces the need for repairs and replacements, resulting in long-term cost savings. Line guards help to ensure that energy flows consistently and effectively.

Line Guard Components

The line guard contains some components designed to protect and extend the life of the conductors. They protect the conductors from mechanical stress, abrasion, and other types of damage. These components need regular inspections to ensure their continued operation. The line guard consists of the following components.

- Helical rods – this is the core component of the line guard which consists of many helical rods. They wrap around the conductor for protection. They are from materials such as aluminium, galvanized steel or stainless steel. Its design matches the diameter and shape of the conductor to ensure a comfortable fit for protection.

- Preformed end fittings – these fittings secure the ends of the helical rods to ensure they stay in place after installation. Its design grips the conductor without causing damage to help in distributing the stress along the length of the line guard. Its materials help to maintain consistency in mechanical and corrosion resistance.

- Spacer rods – these help to maintain a uniform distance between the helical rods and enhance the structural integrity of the guard. Their design helps to ensure the helical rod remains spaced around the conductor.

- Binding wires – these help to secure the helical rods to the conductor at specific points. This is to provide extra stability and ensure the line guard remains in place. They have designs to wound around the helical rods and conductor to keep the assembly stable.

- Protective coating – some of the guards may have an extra protective coating. This is to enhance resistance to environmental factors. Its design applies to the surface of the helical rods and fittings to provide an extra layer of protection.

Line Guard Functions on Transmission Lines

Line guards serve many roles in the protection and maintenance of transmission lines. They contribute to the reliability, longevity, and efficiency of the infrastructure. They help to avoid conductor damage and extend the life of the infrastructure. These features enable line guards to contribute to the reliability of the power transmission system. The line guard serves the following functions.

- Mechanical protection – line guards protect the conductor from mechanical abrasion caused by environmental factors. They also prevent wear and tear at points where the conductor comes into contact with hardware.

- Vibration mitigation – line guards help to dampen aeolian vibrations. These include low-amplitude, high frequency oscillations from wind. Vibrations can lead to conductor fatigue and failure. They also reduce the impact of galloping from wind and ice loading.

- Stress distribution – line guards distribute mechanical stress over a larger are of the conductor. This reduces the risk of localized damage or failure. They also help prevent the conductor from breaking under stress.

- Environmental protection – line guards protect the conductor from corrosion caused by environmental factors. This is including moisture, salt and pollution. They also provide a barrier that can protect the conductor from damage by birds perching on lines.

- Electrical performance – the guards also protect the conductors from mechanical and environmental damage. They help to maintain the electrical integrity of the conductor to ensure efficient transmission of electricity. Line guards keep the conductors in good condition to reduce the electrical losses.

- Ease of inspection and maintenance – line guards serve as visible indicators of potential issues. This makes it easier for maintenance crews to identify and address problems before they lead to conductor failure. They also allow for easy installation and replacement to reduce downtime and labor costs.

Different kinds of line guards

Line guards are available in a variety of styles and designs to suit specific demands and applications. Each type of line guard aims to accommodate distinct climatic conditions, mechanical pressures, and conductor arrangements. It is also advisable to select the proper type of line guard based on the climatic circumstances. This improves the durability and reliability of their transmission infrastructure. Regular inspections and maintenance ensure that the line guards continue to serve their defensive purpose. The following are some common types of line guards.

- Preformed line guards – these are helical-shaped rods that wraps around the conductor. They are from materials such as aluminium, galvanized steel or stainless steel. They have features to fit specific conductor sizes and are easy to install.

- Armor rods – the rods provide extra mechanical reinforcement in demanding applications. They are available in different lengths and diameters to match conductor specifications. They protect against wear and fatigue at crucial points on the conductor.

- Spiral vibration dampers – these consist of helically wound rods that act as dampers. They install at intervals along the conductor to dampen vibrations. They also work in areas with high wind activity to prevent conductor fatigue.

- Spacer rods – these rods install between conductors to maintain spacing and reduce mechanical stress. They help prevent conductors from clashing or getting too close.

- Thermal line guards – these have designs to protect conductors from thermal expansion and contraction. They provide protection against heat-induced sagging or damage. Thermal line guards find use in areas with high-temperatures.

- Insulated line guards – these incorporate insulating materials to prevent electrical faults. They also provide electrical insulation to prevent arcing and electrical discharge. They are effective in preventing bird contact and other wildlife-related issues.

Factors impacting the material choices for line guards.

Choosing the proper material for the line guards necessitates balancing several considerations. This includes environmental, mechanical, and electrical qualities. It is also necessary to consider cost factors, conductor compatibility, and unique application requirements. Line guards are from steel, galvanized steel, aluminium and composite materials. Each of these materials provides unique benefits and qualities. The following considerations influence material choices for line guards.

- Environmental conditions – materials for line guards must be resistant to corrosion especially in areas with salt air. Stainless steel and certain composites offer high corrosion resistance. The material should also be able to resist temperature variations and UV exposure.

- Mechanical properties – the material must have high tensile strength and durability to withstand mechanical stresses. It should also be flexible enough to wrap around conductors and resist fatigue.

- Electrical properties – the electrical conductivity of the material should not affect the performance of the transmission line. Materials with insulating properties prevent electrical faults and improve safety.

- Installation and maintenance – lightweight materials are easy to handle and help reduce labor costs and installation time. Select materials that need less maintenance and have longer service.

- Economic factors – consider the cost of the material selected. Stainless steel offers excellent durability and corrosion resistance but is more expensive. Also, consider the availability of the materials with shorter lead times.

- Compatibility with conductors – the thermal expansion properties of the line guard should be compatible with the conductor material. The selected material should prevent galvanic corrosion.

Challenges and issues with using line guards

There are various issues that impact the use of line guards in overhead transmission lines. These issues may have an impact on their efficacy and lifetime. Also, it is advisable to address these issues to improve efficacy and reliability. The following are the issues associated with the use of line guards.

- Integration with existing systems – ensure the line guards are compatible with existing transmission infrastructure.

- Performance limitations – line guards may not provide enough protection in extreme environmental conditions. They may need extra measures or enhanced designs to balance protection with minimal impact on conductor performance.

- Mechanical stress and damage – continuous exposure to dynamic mechanical stress can lead to material fatigue and failure.

- Material compatibility and durability – line guards should be from materials that resist corrosion, thermal expansion mismatch and environmental degradation.

- Installation challenges – installation of line guards needs precision to ensure proper fit and function. It is also important to use skilled personnel and specialized tools in some applications.

Frequently asked questions

A line guard is a protective component used to protect conductors from mechanical stress, abrasion and environmental factors. It helps to ensure the reliability and longevity of the transmission infrastructure.

Line guards shield wires from mechanical stress, abrasion, and environmental hazards. This ensures that the transmission infrastructure operates reliably, long-term, and efficiently. They help to avoid conductor damage and reduce the likelihood of outages and maintenance requirements.

Line guards serve several functions including mechanical protection, mitigation of vibrations, distribution of mechanical stress and protection against environmental factors.

Common types of line guards include preformed lien guards, armor rods, spiral vibration dampers and spacer rods.