It may surprise you to learn that a crossover clamp can prevent galloping conductors, a destructive phenomenon. The clamps serve as silent protectors of the overhead transmission lines electrical frow. Crossover clamps provide stability and maintain appropriate spacing by stopping the current from charging through. Because of their high strength construction, the conductors are less prone to fluctuations in the wind. On the transmission lines, the clamps install where the conductors cross. Materials used to make crossover clamps include composite polymers, aluminum and galvanized steel. Both conductivity and corrosion resistance are from these materials. Hydraulic crossover clamps are a common type that can manage high tension. Even in situations with strong winds, using crossover clamps in your application helps to guarantee a constant flow of electricity.

Typical components and characteristics of a crossover clamp

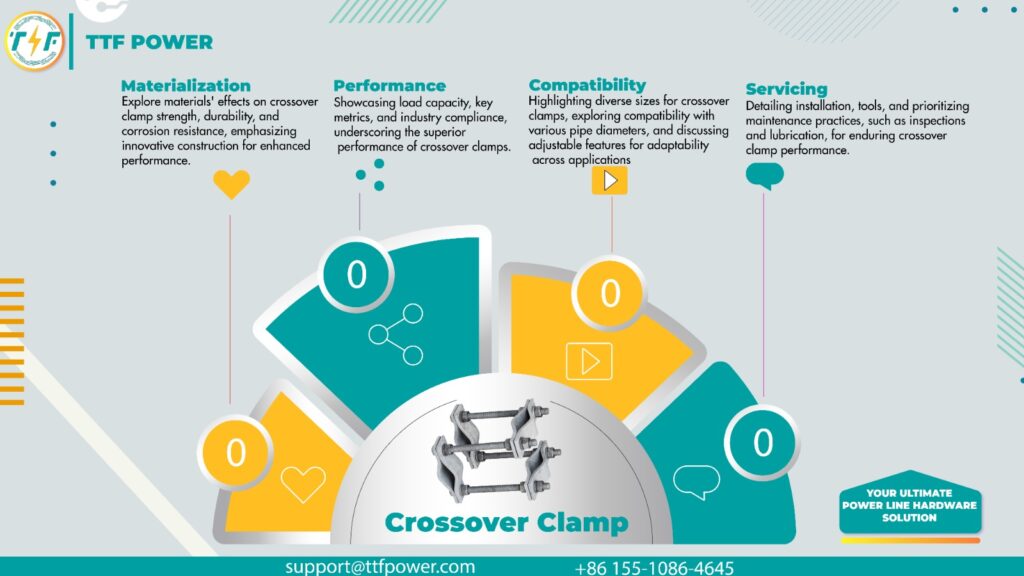

Materials that provide strength, conductivity and corrosion resistance help to make crossover clamps. Depending on the material, crossover clamps have different properties. The selection of materials is contingent upon various aspects, including but not limited to voltage level, conductor type and size, ambient and meteorological conditions and application-specific needs. The components and characteristics of crossover clamps are as follows.

- Stainless steel – crossover clamps made of stainless steel are resistant to corrosion. They are thus appropriate for hostile conditions. They are expensive, but they also provide lifespan and endurance.

- Galvanized steel – this is steel that has coatings of zinc. For outdoor applications, corrosion protection is crucial and this coating offers it.

- Aluminum – aluminum crossover clamps are lightweight and have strong conductivity. This makes them appropriate for electrical applications like transmission lines. Additionally, their resistance to corrosion makes them useful for outdoor applications.

- Conductivity – good conductivity is a need for crossing clamps. This makes it possible for electrical currents to flow.

- Metal clamps – these can work in place of lightweight alternatives made of composite polymers. They also offer strong corrosion resistance. They are also non-conductive electrically and resistant to chemicals and UV light.

- Durability – the clamps must be strong enough to endure repeated exposure to harsh environmental elements, mechanical strains and operating demands.

- Corrosion resistance – to preserve their structural integrity, the clamps must be resistant to corrosion. This is a result of the fact that they install in outdoor settings where they are subject to elements, chemicals and moisture.

- Strength – crossover clamps need to be able to bear loads and mechanical strains. These loads include tension and compression.

- Insulation – conductors and the clamp itself stay apart by insulating qualities. High-temperature resistance is from materials like ceramic inserts and composite polymers. For some applications, they also provide electrical insulation.

What technical requirements should you take into account for crossover clamps?

It is necessary to take the specifications into account while choosing the appropriate crossover clamp for transmission lines. Your applications will run safely and dependably if the technical specs are correct. Depending on the kind of crossover clamp, the clamp’s technical specifications may change. It is also a good idea to review the manufacturer’s specifications and get guidance from experts in the field. The technical specifications for crossover clamps are as follows.

- Size of the conductors – this ensures the clamps will accommodate the diameter and size. Make sure they work with the conductors’ diameter, shape and kind.

- Load capacity – find the largest mechanical stress intended for the crossover clamps. The load capacity depends on variables including tension, compression and bending moments. Take these into account.

- Locking mechanisms – examine the layout and performance of the clamps’ locking mechanisms. Take into account elements like vibration resistance, connection security and ease of installation.

- Temperature range – determine what the crossover clamps operational temperature will be. Make that there is no compromise in the clamps’ ability to tolerate temperature changes.

- Installation specifications – take into account any unique installation specifications. This includes mounting arrangements for accessibility and space constraints. Make sure the clamps work with the tools you have chosen and the installation technique.

- Environmental factors – take into account things like exposure to chemicals and UV radiation.

- Corrosion resistance – check the clamps ability to withstand corrosion. Think about the surface treatment and material composition.

- Voltage rating – verify that the clamps have ratings for the electrical system’s intended voltage level.

- Material – take into account the clamps material composition and examine the material’s characteristics. This includes durability, corrosion resistance, conductivity and strength.

Various kinds of transmission line crossover clamps

On overhead transmission lines, crossover clamps prevent sparks, outages and fires. They come in various designs suited to particular locations and demands. Every crossover clamp has unique advantages and restrictions. The most popular kinds of crossover clamps are as listed below.

- Hydraulic crossover clamps – these clamps grip conductors by using hydraulic pressure. They are thus perfect for demanding settings and high-tension applications.

- Tension clamps – these clamps operate on transmission lines with high voltage and large electrical currents. Their robust designs help to endure very powerful pulling forces. To tightly grasp the conductors, the clamps also feature grooves. This keeps the electricity from slipping and guarantees continuous flow.

- Angle clamps – these clamps function at the intersections of two angled electrical lines. They have a V-shape to ease the intersection of the lines. They are simple to install and maintain and are suitable for low-voltage lines.

- Dead-end clamps – these clamps keep the wires from sagging by securing them to towers or other structures. They support the stability and safety of the line.

- Cable clamps – these are smaller clamps known as cable clamps. They help to protect and insulate cables with a smaller diameter. They work in distribution or telecommunications lines.

- Parallel clamps – when two lines run parallel to one another before crossing, parallel clamps are appropriate. Their robust, straight construction guarantees precise alignment and spacing. They work in high voltage applications, among other things.

Forums and interaction within the community for crossover clamp

Participating in internet communities and forums offers information sharing and the most recent developments in clamp technology. To get further insights, it’s also beneficial to network with specialists in the field. The venues and forums to interact with the crossover clamp community are as shown below.

- Trade associations and discussion boards – this includes communities hosted by websites such as Reddit and Quora. Experts talk about a range of electrical engineering and crossover clamp issues.

- Virtual events – these are events that cover subjects linked to electrical engineering. Sessions on crossover clamps and other overhead parts can be among them.

- LinkedIn groups – these are groups relating to utility infrastructure, power transmission and electrical engineering.

- Manufacturers websites and forums – a few of them have their own online forums. they allow clients to ask questions related to crossover clamps.

Developments in the industry and market updates for crossover clamps

Clamp technology is developing in ways that improve the tools usefulness and effectiveness. The developments show how active the crossover clamp market is. More creative solutions continue to develop which improves sustainability, safety and dependability. Keeping up with these developments enables you to make well-informed choices. It is also a good idea to seek advice on the best developments from industry specialists. The many improvements and advancements in the crossover clamp sector are as listed below.

- Smart technologies – Integration of smart technologies may make real-time monitoring possible. This relates to variables like vibration, load and temperature. Systems for monitoring and sensing are some of these technologies. Predictive maintenance and proactive asset management for transmission lines may enjoy the gathered data.

- Digitalization – crossing clamps with Internet of Things functionality may result from this. This is for control and monitoring remotely. Utilities might be able to respond to maintenance requirements, increase dependability and optimize operations as a result.

- Material innovation – producers create new materials with improved qualities, including composite materials. Enhanced strength, conductivity and resistance to corrosion are some of these qualities. For crossover clamps used in challenging conditions, they provide enhanced longevity and performance.

- Environmental sustainability – this includes the use of sustainable materials and production techniques. Recyclable materials, energy-efficient production techniques and a smaller environmental effect are all included.

- Design optimization – to maximize functionality and convenience of installation, crossover clamp designs may improve. This includes attributes like modular designs that work with varying conductor diameters and adjustable locking mechanisms.

Frequently asked questions

Industry advancements and updates for crossover clamps may include material innovations, design enhancements, integration of smart technologies and digitalization.

You can engage with crossover clamp community and find more information through various online platforms. The forums include online platforms such as electrical engineering forums, LinkedIn groups, online communities and forums, industry associations and forums.

The installation of crossover clamps involves measuring and marking the crossover points, preparing the conductors, positioning the clamp, securing it in place and ensuring proper alignment and continuity.