A B-strand ground clamp is a type of grounding clamp used to establish a reliable electrical condition between a grounding anchor and a bare wire known as a B-strand. In addition to this, the device’s design is for for grounding applications where the conductor to ground is a bare copper or aluminum wire. The ground clamp consists of a durable metal body with a hinged jaw that can open and close. The clamp securely grips the B-strand conductor. On the other hand, they establish a low-resistance electrical connection and provides a convenient and reliable method to connect grounding conductors to the bare wires. B-strand ground clamps are mostly used in electrical grounding systems in power distribution networks, substations and grounding electrode systems. The clamp may have serrated teeth or other features to enhance the grip on the conductor.

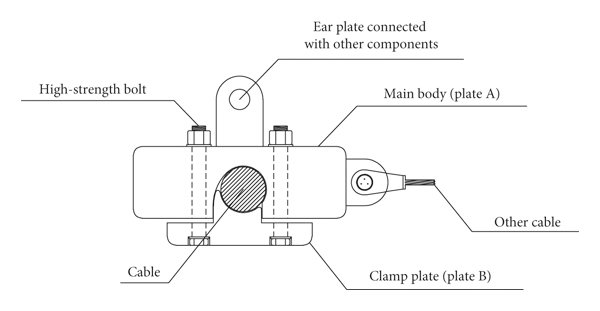

Components of a B-strand clamp

The components of a B-strand ground clamp may vary depending on the manufacturer and the specific product modules. The following are the main components of a B-strand ground clamp are as discussed below.

- Body – the main body of the clamp is from durable metal to provide structural integrity and houses other components of the clamp.

- Jaws – the clamp has jaws designed to grip the B-strand conductor securely for a strong and reliable connection.

- Hinge – the hinge on the clamp allows the jaws to open and close to facilitate the installation and removal of the B-strand conductor. This provides flexibility and adjustability when positioning the clamp around the conductor.

- Bolts/ screws – bolts and screws tighten and secure the jaws around the B-strand conductor to help create a firm electrical connection between the clamp and the conductor.

- Connector/ attachment point – the connector allows for the connection of a grounding conductor which could be a threaded stud, bolt hole or other types of terminal connections.

- Insulation – some of the B-strands may have insulation material applied to certain parts of the clamp to provide electrical insulation or corrosion resistance. This also helps protect the clamp from environmental factors and enhance its performance.

Types of B-strand ground clamps

The term B-strand is commonly associated with copper or aluminum conductors that are specifically designed for grounding applications. the type of ground clamp selected depends on the specific requirements of your grounding application and the conductor size and material. The following are the common types of B-strand ground clamps.

- B-strand ground clamp – This is a type of clamp designed to securely connect a grounding conductor to a B-strand conductor. It features jaws or teeth that grip the B-strand and a terminal for attaching the grounding conductor. They ensure reliable and low-resistance connection.

- B-strand compression connector – Compression connectors creates a tight and reliable electrical connection between B-strand conductors. These connectors consist of a body with a compression mechanism the compresses the conductor strands when tightened. They offer a strong, durable and low-resistance connection.

- B-strand split bolt connector – Slit bolt connectors are another common type of connector used with B-strand conductors and consists of a metal body with a split opening that allows the conductor to insert into. They are easy to install and reliable for the application.

- B-strand grounding clamp with pigtail – This grounding clamp includes a pigtail of wire attached to the clamp and serves as a convenient connection point for attaching a grounding conductor. It eliminates the need for additional connectors or terminals.

Applications of the ground clamps

The use of B-strand ground clamps depends on conductor size, material and the specific of the grounding application. Also, you should adhere to applicable electrical codes, standards and manufacturer guidelines to ensure a safe and effective grounding system. The following are the common applications of the B-strand ground clamps.

- B-strand ground clamps are commonly used in electrical distribution systems such as power transmission and distribution systems to connect grounding conductors to B-strand conductors. This ensures effective grounding and helps protect the electrical infrastructure from faults and transient overvoltages.

- The clamps work in substations and switchyards to establish grounding connections for equipment, structures and conductive parts. This helps create a low-resistance path for fault currents redirecting them safely to the ground.

- They also work in telecommunication systems to establish grounding connections for various equipment and components. This includes in antennas, towers and communication cables. This helps prevent equipment damage caused by lightning strikes and electrical surges.

- The clamps also play a vital role in grounding systems designed to protect the structures and facilities from lightning strikes. They also establish grounding connections for lightning rods, down conductors and grounding electrodes.

- B-strand ground clamps work in various industrial and commercial applications which includes manufacturing facilities, data centers, hospitals and commercial buildings. Also, they help connect the grounding conductors to equipment, machinery, electrical panels and metal structures to ensure proper grounding and mitigate electrical hazards.

Installation process of the B-strand clamps

Some of the B-strand ground clamps come with specific instructions provided by the manufacturer and comply with applicable electrical codes and safety practices. It is advisable to consult a qualified electrician or professional experienced in grounding systems to offer guidelines on the installation. The following is a basic installation process of the B-strand ground clamp.

- Ensure you have all the necessary tools and equipment for the installation including appropriate safety gear.

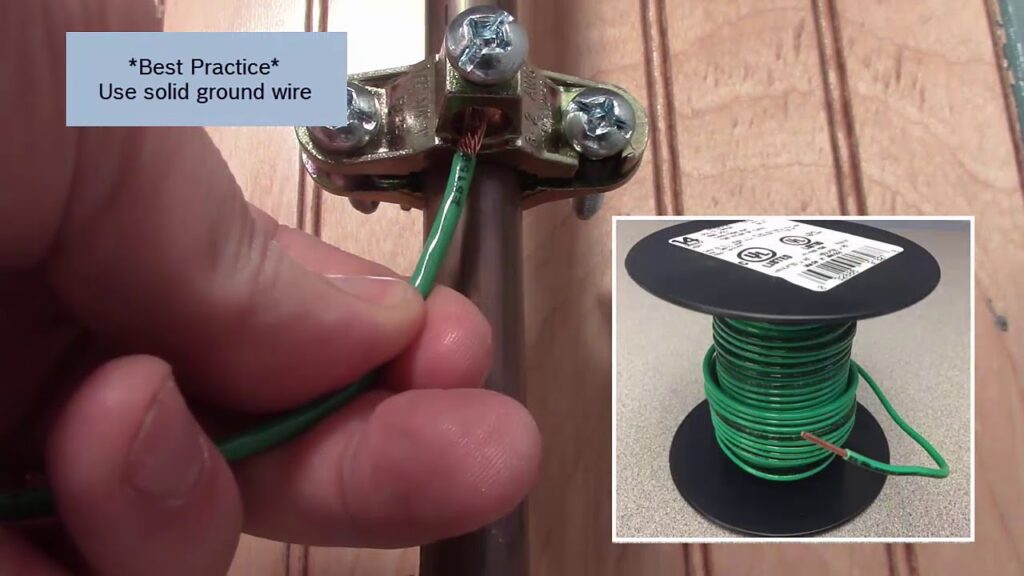

- Take necessary precautions such as wearing insulated gloves, eye protection and other appropriate personal protective equipment.

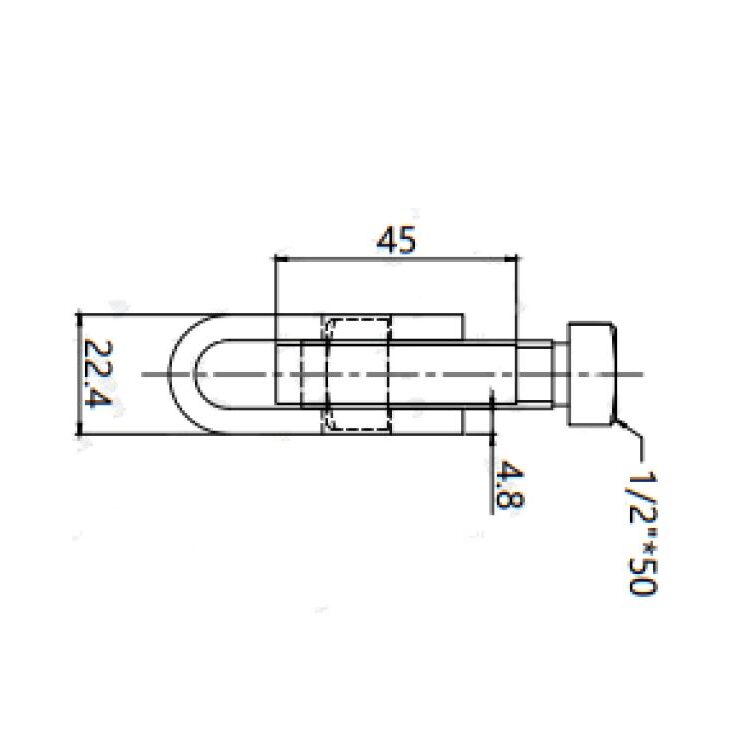

- Choose a B-strand ground clamp that matches the conductor size and material referring to the manufacturer’s specifications and guidelines for selection.

- Ensure the B-strand conductor is clean and free from any dirt, debris or oxidation and other contamination that may hinder the electrical connection.

- Open the jaws of the ground clamp and position the B-strand conductor while aligning the clamp to ensure a secure and reliable connection.

- Tighten the clamp around the jaws of the ground clamp and the B-strand conductor. Apply sufficient pressure to ensure a firm grip on the conductor.

- Perform a conductivity check to ensure a low-resistance connection. The measured resistance should be within acceptable limits as specified by relevant standards.

- Connect the grounding conductor to the terminal provided on the B-strand ground clamp and ensure a secure and tight connection.

- Conduct a visual inspection of the clamp checking for any signs of damage, loose connections or other issues. Furthermore, they perform an electrical testing to verify the effectiveness of the grounding connection

- Keep records of the B-strand ground clamp installation including the clamp type, conductor size, installation date and nay relevant details.

Selecting the best ground clamp for your project

The section process involves a series of factors to consider in order to select the best ground clamp. The selected ground clamp should ensure a reliable and effective electrical connection between the grounding conductor and the B-strand conductors. The following the are the factors to consider during the selection process.

- Ensure that the ground clamp is compatible with the size and material of the B-strand conductor you are working with. The design should accommodate the specific conductor size range and material.

- Consider the specific application and environment in which the ground clamp will install. This includes factors such as indoor or outdoor installation, exposure to moisture or corrosive substances and temperature variations.

- Determine the electrical requirements of your grounding system which should be capable of providing a low-resistance connection to effectively dissipate fault currents or transient overvoltages.

- Select a ground clamp from a reputable manufacturer known for producing high-quality and durable grounding products. A reliable ground clamp should provide long-term performance and withstand environmental factors.

- Consider the installation process and ease of use of the ground clamps. Also, the main features of the ground clamp should include hinged jaws, convenient terminal connections and clear instructions that make the installation straightforward.

- Ensure the selected ground clamp is compatible with other components used in your application.

- Ensure the selected ground clamps complies with industry standards, electrical codes and regulations applicable to your project.