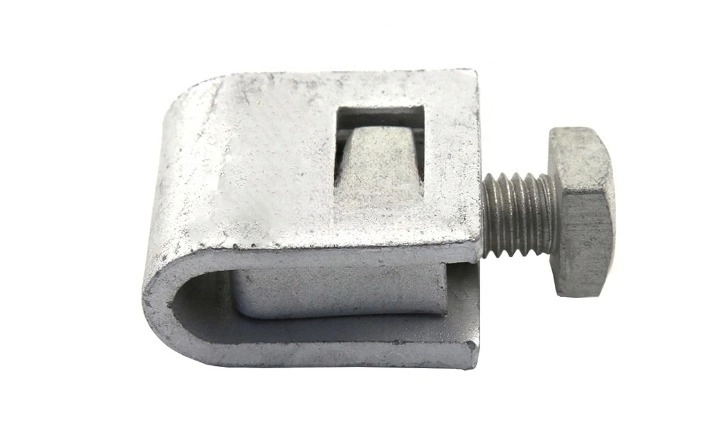

A b strand ground clamp is a specific type of electrical connector used to establish a secure ground connection. It is also known as a messenger ground clamp. The b strand ground clamp has designs to fit around the b strand wire and the grounding conductor. It also includes a bolt or screw to tighten and secure the connection. The b strand ground clamp reduces the risk of electrical shock and equipment damage. This happens by providing a safe path for electrical faults and stray currents. Its main function is to create a grounding connection for electrical systems to ensure safety. It ensures safety by preventing build-up of electrical charge. B strand ground clamps are from conductive materials that ensure good electrical conductivity and resistance to corrosion. These materials include copper, bronze or aluminum.

Application areas of a b strand ground clamp

B strand ground clamps serve in various application areas within the electrical and overhead systems. The ground clamp serves to ensure the safety and reliability of electrical and telecommunication systems. The following are the application areas of the b strand ground clamp.

- Overhead power distribution systems – b strand ground clamps help to ground messenger wires that hold aerial cables. This is to provide a reliable path for fault currents to the ground.

- Telecommunications – the ground clamps help to ground the support wires of telecommunication lines. They help to maintain the integrity of signals by preventing electrical interference.

- Utility poles and towers – they also connect grounding conductors to the support strands of utility poles. It also aids in dissipating lightning strikes to the ground.

- Industrial facilities – the ground clamps work in industrial settings where overhead cables are prevalent to ground various equipment and structures.

- Residential and commercial buildings – b strand ground clamps work in grounding systems for buildings with overhead service entrances.

- Renewable energy systems – they also work in grounding systems of renewable energy installations that use overhead cables.

- Railway electrification – they also support the wires for overhead electrification systems used in railways. They enhance the reliability and safety of the railway electrification infrastructure.

- Street lighting systems – they provide a grounding path for street lightning poles connected with overhead cables. Proper grounding of the street lighting systems prevents electrical hazards.

Challenges facing the use of a b strand ground clamp

Using b strand ground clamps comes with several challenges that can impact their effectiveness and longevity. Additionally, it is advisable to address these challenges by conducting proper installation techniques, regular maintenance and adherence to standards. The following are the challenges facing the use of the b strand ground clamps.

- Environmental exposure – the ground clamps face exposure to moisture, salt and industrial pollutants. These elements can lead to corrosion which compromises the clamps conductivity and integrity. Exposure to extreme temperatures can cause metal expansion and contraction.

- Mechanical stress – overhead systems face vibrations from wind, traffic and other environmental factors. The weight and tension of overhead cables can exert significant strain on clamps. These leads to clamp loosening, wear and potential failure.

- Installation issues – use of incorrect installation techniques can result in poor grounding connections.

- Material compatibility – incorrect match of the metals can lead to galvanic corrosion. This may degrade the materials and the connection.

- Maintenance challenges – regular inspection and maintenance can be a challenge. This is due to the inaccessible nature of overhead systems.

- Electrical load variations – high fault currents can exceed the clamp’s capacity. This leads to overheating and potential failure. Lightning strikes and electrical transients can cause sudden intense currents.

- Aging infrastructure – older systems may use outdated clamps that are less effective or incompatible with newer materials.

Choosing the best b strand ground clamps for overhead installations

There are several types of b strand ground clamps with different designs to select from for your specific needs. There are several factors to consider to ensure performance, safety and longevity. Also, these factors can help ensure you select the ground clamp that provides reliable performance. The following are the factors to consider when selecting the b strand ground clamps.

- Material compatibility – select a clamp made from a material with high electrical conductivity. These materials ensure the clamp material is compatible with the materials of the grounding conductor.

- Environmental conditions – select the clamps with corrosion-resistant properties for harsh environmental conditions. Consider clamps designed to withstand extreme temperatures, UV radiation and other weather-related factors.

- Mechanical strength – ensure the clamp can handle the mechanical load and tension of the overhead cables. Choose clamps that can endure vibrations from wind, traffic and other sources without loosening.

- Electrical specifications – ensure the clamp can handle the expected fault currents and transient currents. The clamps should be suitable for the voltage levels of the electrical system.

- Installation needs – look for clamps that are easy to install and consider the type of tools required for the installation.

- Standards compliance – the clamp should meet relevant local and international electrical and safety standards.

- Maintenance needs – select clamps known for their long-term durability to reduce maintenance needs. Consider ease of inspection as part of routine maintenance.

- Cost and availability – ensure the clamps are readily available from reliable suppliers. This helps to avoid delays in installation. Balance the cost with the quality and performance of the ground clamps.

- Manufacturer reputation – select b strand ground clamps from reputable manufacturers in the market. They should be well known for producing high quality, reliable products.

Installation guide for b strand ground clamps

The installation process for a b strand ground clamp involves several steps to ensure a secure and reliable connection. There are steps that ensure the grounding system is reliable and effective. Additionally, it helps to improve the safety and performance of the electrical infrastructure. The following are the steps involved in the installation of b strand ground clamps.

- Preparation – ensure proper grounding of the electrical system before starting the installation process. Inspect the b strand wire and the grounding conductor for any signs of damage or corrosion. Ensure they are clean and in good condition.

- Gather tools and materials – gather all the necessary tools needed for the installation. These include a wrench or socket set, wire brush, screwdriver and pliers. Ensure you have the b strand ground clamp and any other materials required.

- Cleaning the connection points – use a wire brush to clean the section of the b strand where the clamp will attach. Remove any dirt, oxidation or corrosion to ensure good electrical conductivity.

- Positioning the clamp – open the clamp to allow for easy positioning around the b strand wire and the grounding conductor. Position the clamp around the cleaned section of the b strand wire. Ensure the clamp makes full contact with the wire for optimal conductivity.

- Securing the grounding conductor – place the cleaned end of the grounding conductor into the designated area of the clamp. Tighten the clamp’s bolts or screws and make sure there is secure connection.

- Testing and inspection – check the installation to ensure the clamp is securely fastened and there are no loose connections. Perform an electrical test to ensure good electrical connection between the b strand wire and the grounding conductor.

- Documentation – record the installation details including the date, location and any other observations.

Maintenance and inspection of the b-clamps

Periodic maintenance and inspection of the b strand ground clamps ensures the safety and reliability of the electrical system. It helps to identify and resolve issues before they leading to failures. Additionally, maintenance and inspection helps to take corrective actions to prevent system failures. The following is a guide for maintenance and inspection of the ground clamps.

- Visual inspection –check for signs of corrosion on the clamp, grounding conductor and b strand wire. Check for physical damage such as cracks, bends or deformation in the clamp. Ensure all bolts, screws and fasteners are tight and secure.

- Electrical testing – use a multimeter to check the electrical continuity between the b strand wire and the grounding conductor. Perform a ground resistance test to ensure the grounding system functions as intended.

- Cleaning and maintenance – clean the contact points using a wire brush and ensure the surface is clean and conductive. Re-torque all connections to the manufacturer’s specified values. This helps to maintain a secure and reliable connection. Apply a suitable anti-oxidant grease to the connection points to prevent future oxidation.

- Environmental considerations – consider using extra protective measures such as weatherproofed covers. This helps to shield the clamp from the elements.

- Replacement – replace any clamp that shows signs of wear, corrosion or damage. Review the age and condition of all grounding components and replace as needed.

- Documentation – create reports that include observations, test results and any other actions taken.

Frequently asked questions

A b strand ground clamp is a type of electrical connector used to establish a secure and reliable ground connection. It connects the grounding conductor to the messenger wire, ensure safety and prevents electrical charge build up.

Material compatibility prevents galvanic corrosion which can degrade the materials and connections. This reduces the effectiveness and lifespan of the grounding system.

Common tools include a wrench, wire brush, screwdriver, pliers and other tools specific to the clamp design and installation needs.