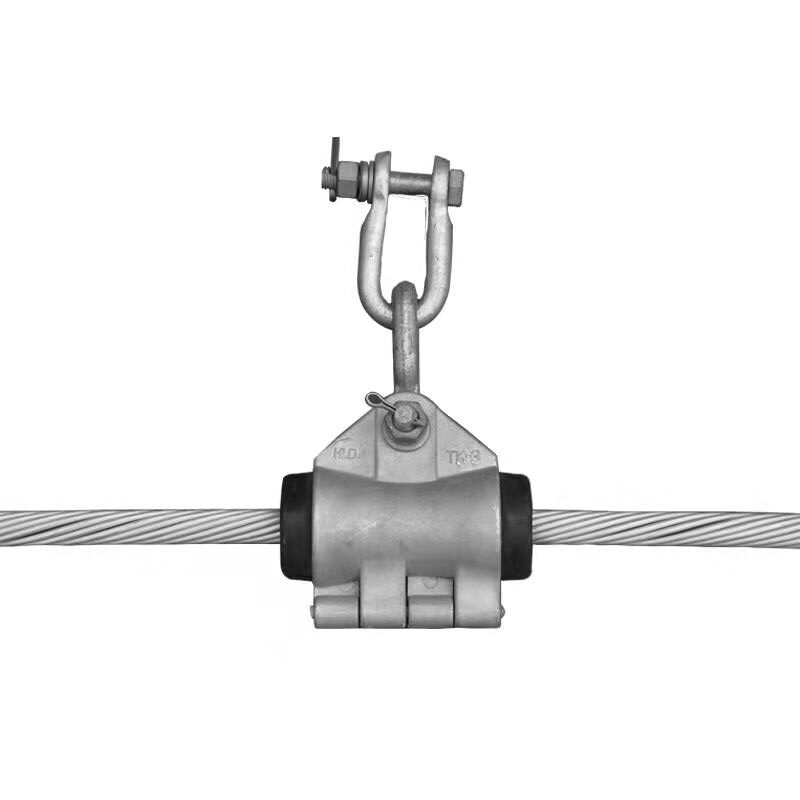

Armor grip suspension is a type of hardware used on the overhead power line systems. It has a design that provides support and strain relief for cables especially the ADSS and OPGW cables. Armor rods maintain the proper sag and tension of the cables. They protect them from environmental conditions, mechanical support and reduce the risk of damage. Common types include single armor grip suspension, double armor, fork-type and oval shaped armor grip. It installs by first attaching the suspension clamp to the supporting structure like pole or tower. They help to cut the stress and strain on the cables and ensure stability and durability. The hardware is hot dip galvanized that makes them resistant to rust and corrosion for durability.

Benefits and applications of armor grip suspension

Armor grip suspension provides various benefits to power line applications. They offer alternatives to traditional armor-clamp combinations for power line suspension. These benefits include weight reduction, improved installation, improved vibration damping and reduced compression stress. They find use in various applications in the industry sector. The following are the various applications of armor grip suspension.

- Overhead transmission lines – armor grip suspensions provide secure anchoring for conductors. They also offer reduced stress and fatigue at critical locations.

- Distribution lines – the grips help in tap connections, urban areas, line upgrades and rehabilitation. This helps in reducing clutter and ensure reliable and long-lasting solution.

- Overhead ground wires – they also provide a robust protection and vibration dampening to reduce noise and fatigue.

- Guyed structures and towers – armor grip suspensions help to secure guy wires and offer improved stability.

- Fiber optic integration – incorporation of fiber optic cables within the armor rods enables data transmission alongside power lines.

Challenges and issues associated with power lines

Armor grip suspension also present challenges that may hinder the performance of the armor grip suspension. It thus requires careful planning, qualified personnel and collaboration with experienced manufacturers. This helps to mitigate the challenges and adapt the full potential of the innovative technology. The following are the various challenges facing the use of armor grip suspension.

- Installation requirements – the installation of armor grip suspension requires trained personnel. Lack of proper installation compromises the performance and reliability of the suspension.

- Design variations – armor grip suspension is available in various designs and sizes. The size and design depend on specific conductor sizes and load requirements.

- Environmental conditions – armor grip suspensions are greatly affected by various environmental factors. Some specific designs offer anti-corrosion which may increase complexity and cost.

- Initial cost – some designs and specialized materials of armor grip suspension leads to high costs. It may also lead to increased costs during maintenance.

- Compatibility – armor grip suspensions may not be compatible with existing hardware and infrastructure. Adaptation to existing structures need extra modifications which increases costs.

- Potential conductor damage – armor rod suspension may pose damage to conductor due to improper alignment.

Selection criteria for armor grip suspension

Proper selection of armor grip suspension ensures the reliability and safety of the applications. The process involves considering various factors that help in the decision making. Additionally, it is advisable to consult with experienced engineers to navigate the options. The following are the factors to consider during the selection of armor grip suspension.

- Initial cost – consider the initial cost of the suspension and balance with the quality and performance of armor grip suspension.

- Installation and maintenance – examine the availability of trained personnel and specialized tools needed.

- Compatibility – consider the ease of integration of armor grip suspension with existing hardware. This should aim to reduce disruption and complexity.

- Material – consider the material used in the manufacture of armor grip suspension. Choose the material that offer durability, strength and corrosion resistance.

- Environmental conditions – various conditions such as excessive wind, ice accumulation and corrosion need suspensions with resistance.

- Size and material – select the armor grip that fits the conductor diameter and is compatible with the material.

- Load requirements – consider the line tension and expected loads the suspension will hold. Select a design with enough strength and load capacity to ensure safe and reliable operation.

Installation of armor grip suspensions

The installation of the armor grip suspension involves the use of various components like armor rods, suspension clamps and preformed wire grips. It is vital to follow specific guidelines provided by the cable manufacturer and adhere to industry best practices. It is also recommended to consult with experienced professionals to ensure a proper and reliable installation. The installation steps are as follows;

- Preparation – preparation is important to ensure all necessary equipment and components are available. This includes the other attachment hardware like nuts and bolts.

- Cable preparation – cleaning and inspection of the cable surface is necessary to check for damages and defects. Any debris or contaminants may interfere with the installation process.

- Positioning of the suspension clamps – this involves determining the locations where the suspension clamps will install along the cable route. This spacing should be according to the specifications from the manufacturers.

- Attachment of suspension clamps – attach the suspension clamps to the pole or tower using the appropriate attachment hardware. This ensure that the clamps are securely fastened and aligned properly.

- Place the armor rods – armor rods install near the suspension clamps over the cable. The number depends on the cable diameter and design specifications.

- Secure the armor rods – install the preformed wire grips over the armor rods at both ends. This is to tighten the wire grips to ensure a firm grip on the armor rods without causing any damage to the cable.

- Tensioning – the tension should be within the recommended range specified by the cable manufacturer.

- Inspection and testing – inspect for any signs of misalignment, loose components or damages.

Cost considerations for armor grip suspensions

The cost of armor grip suspension depends on various factors and conditions. These factors include performance, reliability, type and material. The initial cost should also factor in the overall maintenance and installation costs. The following are the factors that influence the cost of armor grip suspension.

- Conductor size – large conductors lead to higher costs for the armor grip suspensions. The prices range from $1- $4 depending on size.

- Design – design of the armor grip suspensions may be single grip or double grip. Single grip setups are cheaper than the double grips.

- Quantity and manufacturer – purchasing in bulk may come with discounts depending on the manufacturer.

- Performance – select the design that best suits your performance and reliability needs. The price may be slightly higher than the basic armor grip suspensions.

- Material – armor grip suspensions is from various materials. These materials include galvanized steel, composite materials or aluminum. The prices may vary depending on the selected material.

Supplier and vendor information

There are various manufacturers and suppliers for armor grip suspensions available in the market. They may influence the price and availability of armor grip suspensions. TTF Power Systems offer various types and designs of the armor grip suspension. TTF Power offer a wide range of types and designs of armor grip suspensions. They have strict adherence to custom design, product quality and reduced overall cost. The following is their contact information.

Landline (M-F, 9 am-6 pm): (+86) 22-8523-3528

Cell Phone: (+86) 155-1086-4645

Customer Service: support@ttfpower.com

Community forums and expert interactions for armor grip suspensions

Use of armor grip suspensions can become easier through finding the right online communities and expert interactions. It helps in knowledge sharing, insights and experiences. Additionally, it is advisable to clearly state your questions and concerns, provide details about your specific application and engage in discussions. This helps to understand and broaden your understanding of armor grip suspensions. The following are the various forums for engagement.

- Electrical contractor forums – these are forums like Home Power Forum or ElectricianTalk. They attract experienced electricians who have experience in using armor grip suspensions.

- Manufacturer websites – most of manufacturers may provide contact forms or customer support channels. These help to directly reach their technical experts for guidance.

- Trade shows and conferences – this includes attending industry trade shows that provide opportunities to meet different manufacturers. You may also learn about new technologies and network with experts in the field. Such platforms include T&D World Exhibition and DistribuTECH.

- Technical articles – check for publications from well known organizations for research on performance and applications of armor grip suspensions.

Frequently asked questions

It is a preformed metal rod that grips and supports overhead power line conductors. It offers more benefits compared to traditional clamps.

There are various types including single, double, fork-type, oval-shaped and ground wire type. They are from various materials with extra features such as dampers or coatings.

Consider factors like conductor size, design type, extra features, quantity and manufacturer when estimating costs. Initial costs may be higher than traditional clamps and may offer longer lifespan and reduced maintenance costs.

Always follow recommended safety protocols for working with overhead power lines. also, consult with qualified personnel for installation and maintenance.