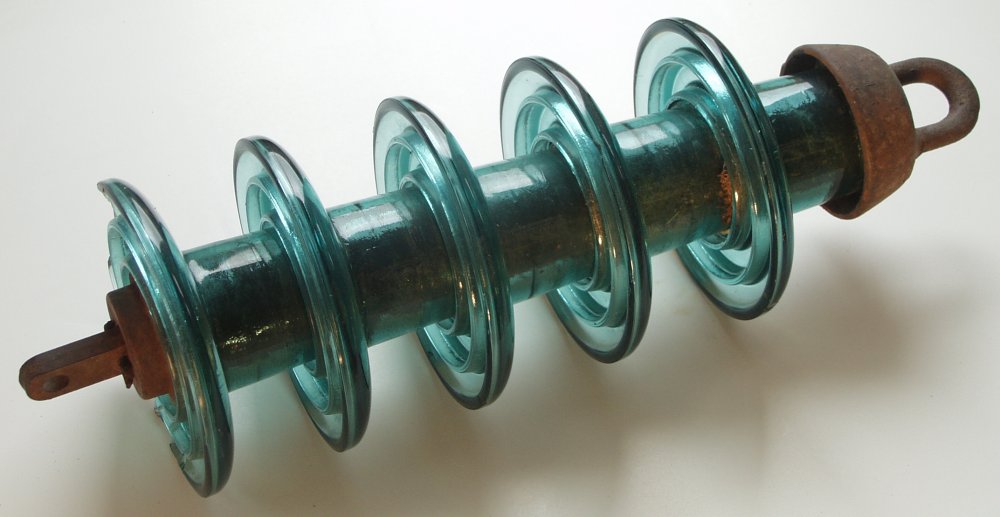

A suspension insulator is a component that supports conductors and provides insulation. It has an insulating core made of materials like porcelain, glass, or composite. It suspends from a supporting structure and provides support for the electrical conductor. This is by restricting the flow of electric current from the conductor to the support structure. Suspension insulators protect the integrity and safety of the electrical installation. This is by ensuring enough electrical insulation and mechanical support. Suspension insulators serve a purpose in ADSS and OPGW cables in a variety of applications. They offer mechanical support, electrical insulation, spacing, and sag control. They provide lightning protection to guarantee that the systems operate safely and reliably. Common types of insulators include cap and pin, interlink, and material-based suspension insulators.

Materials used in the production of suspension insulator

Suspension insulators consist of materials that provide both mechanical strength and electrical insulation. Material selection depends on by a variety of factors. These include operating voltage, ambient conditions, and mechanical loads. Each of these materials has characteristics that contribute to their performance and dependability. The following materials are work for suspension insulators.

- Porcelain – this is a material that provides both electrical insulation and mechanical strength. Porcelain insulators are from high-strength clay, feldspar, and quartz burned at high temperatures. They can endure applications with varying weather conditions and voltage levels.

- Glass – the insulators are from toughened or tempered glass. This gives adequate mechanical strength and resistance. Glass insulators are effective in high-pollution locations and coastal environments.

- Composite materials – composite suspension insulators are from fiberglass plastic or silicone rubber. The materials provide advantages such as lower weight, mechanical strength, and increased pollution resistance. They work in polluted areas, coastal regions, and locations prone to vandalism.

- Metal components – galvanized steel or aluminum, contribute to offer strength and longevity. Metal end fittings attach to the insulating core, supporting the conductor and connecting it to the support structure.

Technical standards for suspension insulator.

Technical parameters for suspension insulators differ depending on a variety of circumstances. These variables can help you choose suspension insulators that fit your individual needs. It is also recommended that you request specifications from manufacturers to make the best selection. These are the technical specifications for suspension insulators.

| Universal Model | U160B/170 | U160B/155 | U160B/146 |

| ( mm ) Diameter | 280 | 280 | 280 |

| ( mm ) Height | 170 | 155 | 146 |

| ( mm )Leakage distance | 400 | 400 | 400 |

| ( mm )Coupling | 20 | 20 | 20 |

| ( kN ) SML | 160 | 160 | 160 |

| ( kN )Tension Load Test | 80 | 80 | 80 |

| ( kV )Power frequency Withstand wet | 45 | 45 | 45 |

| ( kV )Lightning Impulse Withstand | 110 | 110 | 110 |

| ( P.U )Puncture Impulse Voltage | 2.8 | 2.8 | 2.8 |

| ( kV )Puncture power frequency voltage | 130 | 130 | 130 |

- Voltage rating – Insulators are available in a variety of voltage ratings to suit different applications. They function with a variety of voltage ratings, including low and medium. They also work at high, extra-high, and ultra-high voltages. The rating indicates the insulator’s capacity to endure electrical stress without failure.

- Mechanical strength – they should be strong enough to sustain the weight of the conductors. The specifications include tensile strength, compression strength, bending strength, and impact resistance.

- Dimensional parameters – the insulators have defined dimensions. This includes the length, diameter, shed profile, and fitting specifications. The specifications help to ensure that the transmission line operates reliably.

- Material composition – consider the material composition of the insulating core and other components. The composition influences features like electrical insulation, pollutant resistance, and durability.

- Corona performance – Insulators with strong corona performance reduce energy losses, electromagnetic interference, and ensure line reliability.

Industry improvements and updates for suspension insulators.

There have been various developments and modifications to the suspension insulator sector. They strive to improve performance, dependability, and sustainability. Additionally, it is advisable that you check with specialists for advice on suspension insulator changes. The suspension insulator sector has seen the following advances and modifications.

- Composite materials – these are including fiberglass reinforced plastic and silicone rubber. These materials offer advantages such as lower weight, increased mechanical strength, and improved pollutant resistance.

- Integrated monitoring systems – some of the insulators include integrated monitoring systems that offer real-time data. This contains information about insulation performance, temperature, humidity, and pollution levels. The systems assist utilities in detecting possible faults early, optimizing maintenance schedules, and increasing reliability.

- Smart insulator technologies – there are attempts underway to integrate smart technologies with insulators. These include embedded sensors, communication capabilities, and self-diagnosing systems. The technologies allow for the monitoring, predictive maintenance, and remote management of transmission line assets.

- Standardization and certification – attempts are underway to standardize suspension insulator requirements. This ensures uniformity, interoperability, and quality across several manufacturers and geographies. Standardization makes it easier to find insulators that fulfill certain performance and reliability standards.

- Advanced shed designs – manufacturers provide improved shed designs for suspension insulators. This aims to improve pollutant performance and lessen the likelihood of flashovers in contaminated situations. These designs incorporate better shed profiles, hydrophobic coatings, and surface treatments.

- High voltage applications – increasing demand for high voltage transmission lines drives the development of higher voltage insulators. There is ongoing development to fulfill the needs of extra-high and ultra-high voltage applications.

- Environmental sustainability – this incorporates into the design and production processes. This involves employing environmentally friendly products and conserving energy throughout production processes.

Advantages and disadvantages of suspension insulators.

Suspension insulators have many benefits, including performance, dependability, and durability. Insulators confront a variety of obstacles in their application. These include pollution levels, mechanical stress, and environmental degradation. The following are the benefits and drawbacks of suspension insulators.

Advantages

- Electrical insulation – insulators prevent current from flowing from the conductor to the supporting structures. This ensures the transmission line’s integrity and safety. This is by ensuring electrical insulation.

- Durability – Insulators can survive harsh weather conditions, ensuring long-lasting performance. They can withstand high winds, temperature variations, pollution, and ultraviolet light.

- Cost effectiveness – insulators are more cost-effective for transmission lines than other technologies. They need minimal maintenance and have a long service life, lowering operational costs.

- Mechanical support – insulating materials bear the weight of the conductors and can sustain mechanical stress.

- Versatiltiy – insulators work in a variety of voltage levels and environmental circumstances.

- Installation is simple – the insulators have designs to be easily installed and replaced. This helps to reduce downtime during building.

Disadvantages

- Pollution performance – pollution buildup can undermine their insulating characteristics, resulting in tracking.

- Mechanical stress – Insulators face to mechanical stresses in their applications. This encompasses wind, ice, conductor strain, and vibration. This can cause fatigue failure, cracking, or breakage of insulator components. This may jeopardize their structural integrity and reliability.

- Vandalism and wildlife interactions – suspension insulators are vulnerable to vandalism or damage by wildlife. This can cause power outages, equipment damage, and safety hazards.

- Aging infrastructure – existing suspension insulators need replacement. This is to ensure dependability and safety in an aging infrastructure.

- Environmental conditions – the insulators must be able to tolerate a variety of environmental conditions. This includes severe temperatures, UV radiation, dampness, and earthquake occurrences.

Differences between disc and suspension insulators

Transmission and distribution lines use both disc and suspension insulators. Disc insulators originate out of a stack of ceramic or glass discs with a metal pin through the middle. The discs can group in a vertical or horizontal arrangement. Suspension insulators are longer and made up of insulating components strung in a string. Each unit features a cap and pin arrangement, with the conductor connected to the bottom pin. Disc insulators are suitable for low to medium voltage distribution lines and substations. Suspension insulators work in medium-to-high voltage transmission lines.

Frequently asked Questions

Disc insulators are small structures made out of stacked ceramic or glass discs connected by a central metal pin. It operates in low- to medium-voltage applications. Suspension insulators are longer strings of insulating units that have a cap and pin configuration.

The voltage rating of suspension insulators is depending on criteria such as material composition, creepage distance, pollution performance, and mechanical strength.