A guy wire is a tensioned cable used in the construction and support of overhead transmission lines. It is also known as a guy rope or a guy cable. It helps to provide extra stability and support to the structures to prevent them from leaning or toppling over. Guy wire helps to prevent the damages caused by load from wind, ice and weight of transmission lines. It installs at an elevated angle from the structure to the ground. This helps to ensure the supported structure remains stable and upright under various conditions. South America requires the use of high-quality guy wires to ensure the reliability and stability in the challenging terrains. The examples of guy wires include stranded guy wire, solid, aluminum, helical and extra high strength guy wire. They find use in applications such as telecommunications, wind turbines, coastal structures and construction support.

Key features of guy wire

Guy wire consists of various features that help them to provide the necessary support. The specific features vary depending on the type and design of the application. The following are the key features of the guy wire.

- High tensile strength – this helps them to withstand significant tensile loads. It is from high strength materials such as steel that helps provide this stability.

- Corrosion resistance – this feature mostly helps in outdoor and exposed applications.

- Diameter and length – they are available in different diameter and lengths to accommodate various loads and heights.

- Ease of installation – guy wires work with connectors and tensioning systems. This is to help provide simplicity in installation.

- Customization – the availability of customization helps to meet specific requirements of the project. This may include coating, materials and configurations.

- Flexibility – they are available in strands which makes them flexible. This helps to allow for absorption and force distribution.

- Durability – they are able to ensure the tests of time for longer serviceable life.

- Vibration dampening features – this feature helps to dampen vibration. It also helps to reduce the oscillations and sway.

- Aesthetic consideration – guy wires have special coatings to help in the physical appearance.

Selection and installation of guy wire

The selection process of the guy wire is a crucial step to ensure you select the best wire for your project. It includes considering several factors such as load, material, wire diameter, environmental conditions, coating, installation and costs. The installation should ensure the stability and safety of the supported structures. Additionally, it is advisable to consult with industry professionals whenever in doubt. The following is a general installation process of the guy wire.

- Site assessment – conduct an assessment to understand the terrain, environmental conditions and any challenges. Ensure you have all the necessary safety gear and ensure proper use.

- Design and engineering – this involve determining the number of guy wires needed, where to install them and the tension levels.

- Material and component finding – purchase the necessary materials required for the installation. This includes guy wires, anchors, hardware among others.

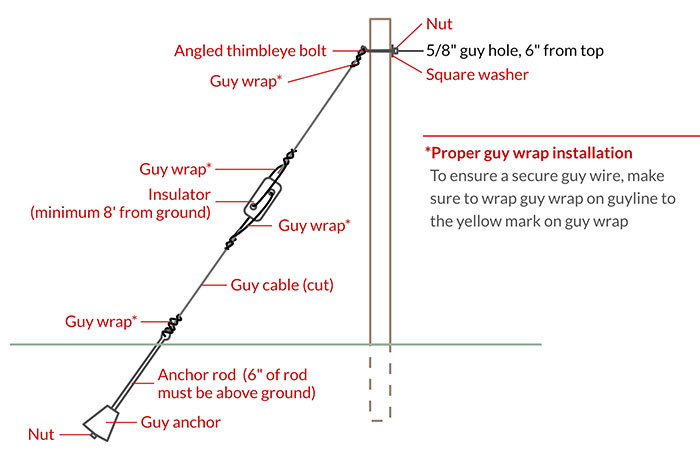

- Anchor installation – install the anchors at the determined anchor points. This depends on the type of application. It should embed in the ground or attach to a solid structure.

- Guy wire installation – attach one end of the guy wire to the anchor point and the other end to the structure to support. Ensure proper tensioning following design specifications.

- Alignment and angle adjustment – adjust the angles of the guy wire to ensure the proper alignment and tension.

- Hardware installation – secure the guy wire to the anchor points using proper hardware and ensure the proper tension.

- Inspection – inspect the installation to check for any defects, lose connections and any other issue.

- Tension tests – confirm the tension of the guy wires using suitable tensioning measuring tools. This is to ensure they meet the design specifications.

- Documentation – keep proper records of the installation process. This is including design plans, inspection reports and tensioning measurements.

Maintenance and inspection of guy wire

Proper maintenance and inspection of guy wires help to ensure the safety and reliability of the structures. The frequency depends on the environmental conditions in the installation area. This also helps to identify and address potential issues before they cause failures of accidents. In addition, it is advisable to perform periodic professional inspections. The following is a basic guide for the maintenance and inspection of guy wires in South America.

- Establish a regular schedule for inspecting and maintaining the guy wires. Tis could be annually, or semi-annually.

- Conduct visual inspections to check for signs of wear, damage or corrosion. This helps to identify corrosion, wire condition and hardware conditions.

- Measure the tension of the guy wire to ensure they are maintaining the desired tension as required. Do this using the necessary tensioning tools.

- Evaluate the stability of the anchor points in areas prone to soil erosion and ground movements.

- Assess the environmental condition of the installation area. This is including high winds, heavy rainfall and temperature variations.

- Replace any affected components that show wear, damage or corrosion.

- Maintain detailed records of the inspections and maintenance activities. Include the dates, findings and actions taken.

Comparative analysis of guy wires in South America

A comparative analysis includes evaluating and assessing the various factors that influence the selection of the guy wires. This includes assessing the types, designs, brands and manufacturers and suppliers available in the market. This helps to ensure the stability and safety of various structures across the region. Also, it is advisable to consult with industry professionals for guidance on the best guy wire for your project. The following are the factors to include in a comparative analysis in South America.

- Aesthetic considerations – the guy wires should be aesthetically appealing especially for the urban areas.

- Maintenance – assess the frequency of maintenance and inspection of the guy wires. Check the environmental conditions that may provoke more frequent maintenance.

- Materials and coatings – check the materials and coatings to support the load requirements, resist corrosion and meet the budget.

- Industry applications – development of various applications influence the demand for guy wires. Guy wires work in applications such as power transmission, telecommunications, renewable energy and infrastructure development.

- Environmental conditions – south America has a diverse range of environmental conditions. These include coastal regions, mountainous areas and tropical rainforests.

- Local expertise – check the availability of local expertise to meet the regional challenges.

- Budget considerations – the costs of the guy wire may influence the choice of material, coatings and maintenance practices.

Certifications and standards in South America

Standards and certifications help to ensure the quality and performance of the guy wires in South America. These standards vary depending on the country and the international standards. Additionally, it is important to ensure the guy wires comply with the relevant standards and certifications. This helps to maintain the safety and quality of the wire in various applications. The following are the standards and certifications in South America.

- ISO 6892-1 – this is a standard that specifies the method for tensile testing of metallic materials. It helps to determine the tensile strength, yield strength and elongation of the materials used.

- ASTM standards – this standard covers various aspects of wire and strand for use in structures. They provide guidelines for the properties of the wire materials and strand construction.

- IEC standards – this is international standards for test methods and requirements of bare overhead conductors.

- ANSI standards – these are American standards for guy wires use in south America.

Regional market for guy wire in South America

There are various factors that influence the regional market for guy wire in south America. This also influences the demand and availability of guy wires in the market. Additionally, it is advisable for manufacturers and suppliers to understand the specific requirements and challenges of the market. The following are the factors that shape the regional market for guy wires in South America.

- Regulations – compliance with local regulations impacts the regional market for guy wires. This is because the region has various standards and regulations.

- Rural areas – guy wires help to support structures in the rural areas like electric fences and utility poles.

- Coastal regions – corrosion resistance guy wires find use in the coastal areas due to presence of saltwater.

- Infrastructure development – guy wires also help in the construction of bridges, overpasses and observation towers.

- Mining and industrial sectors – guy wires also support equipment and structures in the challenging environments in mining sectors.

- Environmental conditions – South America has a wide range of environmental conditions. These conditions influence the demand and availability of guy wires.

Frequently asked questions

A guy wire is a tensioned cable used to stabilize and support various structures in south America. They help to provide stability and prevent structural sway and bending in regions with diverse environmental conditions.

Guy wires find use in various applications including power transmission, telecommunications, renewable energy, infrastructure development, oil and gas and coastal protection.

Signs of wear or damage include corrosion, broken wires, loose connectors, alignment issues or deviations from the desired tension levels.