An alley arm is a device used to support and position electrical equipment and conductors on a utility pole. It creates lateral extension from the pole which allows for the installation of extra equipment and conductors. It provides space for components while keeping them clear of the pole and conductors. This mainly helps prevent electrical interference and ensuring safety. Alley arm is from materials such as steel or aluminum shaped like an “T” or” L”. Utility companies in South American countries depend on strong alley arms. This is to support transformers and maintain reliable electricity distribution. Common types of alley arm include straight alley arm, offset alley arm, double alley arm and crossarm alley arm. They find use in distribution and sub transmission systems to expand the capacity and functionality of the utility poles.

Key features of alley arm

Alley arms consists of various features that make them a vital component on the systems. They help to support and organize equipment and conductors on utility poles. These components offer different designs, strength and adaptability. This is crucial for maintaining the reliability and safety of the systems. The following are the key features of the alley arm.

- Lateral support – alley arms provide side-to-side support for electrical equipment like conductors. This mainly helps maintain the stability of the equipment.

- Extension from pole – they also extend horizontally from the pole to create extra space for attachment of equipment. It also keeps the equipment clear of the pole to reduce the risk of electrical interference and ensuring proper clearances.

- Versatility – they have various designs that allow them to accommodate different types of equipment. These designs include straight, offset, double, triple and more.

- Material – they are from durable materials that are capable of withstanding mechanical loads and environmental conditions. These materials include steel and aluminum.

- Jumper attachments – they may also have provisions for attaching jumper cables or connecting wires between conductors.

- Grounding – alley arms support grounding devices to enhance the safety of the electrical system.

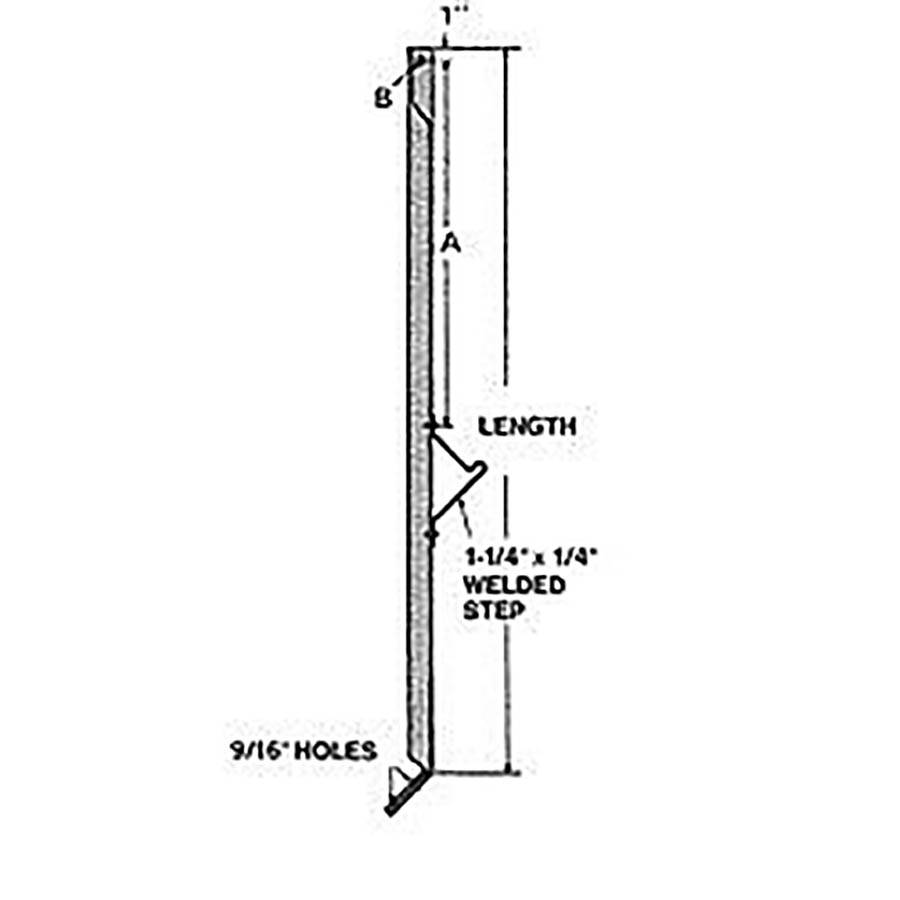

- Mounting points – alley arms have multiple attachment points with holes. This is to allow for the secure mounting of equipment.

- Anchor points – the anchor points help to tension conductors which helps maintain the tension and stability of the electrical system.

- Weather resistance – alley arms have coatings that help them withstand weather conditions. This is including exposure to rain, wind and UV radiation.

Selection and installation of alley arms

Selection of alley arms in South America involves considering several factors. These include load requirements, configuration, material, clearance requirements, costs, weather resistance, voltage and current rating. The installation process should aim to ensure safety and reliability of the electrical system. Also, it is crucial to follow safety guidelines, electrical codes and seek professional guidance. The following is a basic installation process of the alley arm.

- Site assessment – conduct a thorough site assessment to determine the suitable locations for installation. Consider factors like spacing, clearances, load-bearing capacity and proximity to other equipment.

- Permits – get the required permits and permissions for the installation from the local authorities.

- Material and equipment – acquire the necessary alley arms and associated hardware. This is including insulators and transformers.

- Safety precautions – follow all the safety procedures recommended and de-energize the electrical lines. This helps prevent electrical accidents during installation.

- Preparation – inspect and prepare the utility pole where the alley arm will mount. This consists of cleaning the pole surface, checking for damage and making any required repairs.

- Mounting – install transformers, insulators, crossarms, lightning arresters or any other as needed. Attach conductors to the appropriate hardware on the alley arm.

- Grounding and bonding – establish grounding connections as recommended. Also, ensure electrical safety and proper grounding of equipment.

- Safety and quality checks – conduct safety inspections and quality checks. This is to ensure all components are properly installed and secured.

- Energization and testing – energize the system with the utility company. Perform tests to ensure safety and proper functioning.

- Documentation – keep detailed records of the installation including drawings, specifications and inspection reports.

Maintenance and inspection of alley arm in South America

Proper maintenance and inspection of alley arms ensures the reliability and safety of systems. It also helps identify issues early and prevent failures and extend the lifespan of alley arms. Additionally, it is advisable to consult professionals for maintenance and inspection once in a while. The following is a basic inspection and maintenance guide for alley arm in South America.

- Perform regular cleaning to remove dirt, debris and vegetation that accumulate on the surface. This helps prevent corrosion and ensure a clear visual inspection of the alley arm.

- Check for signs of corrosion on the alley arms surface and apply a protective coating to prevent deterioration.

- Inspect the fasteners, bolts, and brackets used to secure the alley arm to the utility pole. This is to ensure they are tight according to the manufacturer’s recommendation.

- Verify the integrity of the grounding system associated with the alley arm. Ensure the grounding conductor are in good condition.

- Inspect the insulators for cracks, damage or contamination and consider replacing.

- Maintain vegetation clearance around the alley arms to prevent overgrowth that could interfere with equipment.

- Conduct regular inspections of the alley arm to check for visible signs of damage, wear or corrosion.

- Confirm that the clearances between conductors, equipment and the utility pole meet the safety and regulatory standards.

- Assess the load-carrying capacity of the alley arm to ensure it can safely support the equipment and conductors attached.

- Keep detailed records of the inspections including dates, findings, and any maintenance or repairs performed.

Comparative analysis of alley arm in South America

Comparative analysis involves assessing different aspects of alley arm products. Consider the different designs, types and costs available in the market to select the best alley arm. The following are the key factors to include in a comparative analysis in South America.

- Types and configurations – compare the availability of various types of alley arms. Check which configurations are commonly used and suitable for different applications.

- Material and durability – analyze the materials used in manufacturing of the alley arm. Asses their resistance to corrosion. Consider the expected lifespan and maintenance requirements of different materials.

- Load capacity – compare the load-carrying capacities of different alley arms. This is to ensure they meet the requirements of the electrical distribution systems.

- Weather resistance – consider how they withstand the diverse weather conditions in South America. These conditions include heavy rainfall high winds and exposure to UV radiation.

- Cost and availability – compare the costs of alley arms from different manufacturers or suppliers. Assess the local availability of the products and import options.

- Grounding provisions – examine the provision of rounding features in alley arm designs for safety.

Certifications and standards in South America

There are various standards and certifications that govern the use of alley arms in South America. They help to ensure quality, safety and reliability of the overhead distribution systems. The following are the main standards and certifications in South America.

- IEC standards – these are international standards adopted by South American countries for alley arms.

- ISO standards – these are standards related to materials, manufacturing and quality management relevant to production and quality control.

- National electrical codes – South American countries have their own national electrical codes. They set standards for the design, installation and maintenance of electrical equipment like alley arms.

- ASTM standards – these includes standards for materials and testing methods. This is particularly for components like fasteners, bolts and steel used in alley arm construction.

- NEMA standards – these are standards that cover various electrical equipment and may be relevant to alley arms.

- Local testing and certification – some of the countries may require products like alley arms to undergo testing and certification by local testing laboratories.

Regional market for alley arm in South America

The regional market encompasses a diverse group of countries such as Brazil, Argentina, Chile, Peru, Colombia, Venezuela and Ecuador. There are various market trends that influence the regional demand and availability of alley arms. They also depend on electrical infrastructure, regulatory environment and market dynamics. The following are the common factors that increase demand for alley arms in South America.

- Supplier diversity – South American market consists of both local and international manufacturers and suppliers.

- Electrification of projects – rural electrification brings electricity to remote areas which increase demand for alley arms.

- Urbanization – urbanization leads to increased demand for reliable electrical distribution systems.

- Upgrades and maintenance – the need for maintenance, replacement and upgrades increase demand for alley arms.

- Environmental considerations – environmental conditions influence the choice of materials and coatings for alley arms. This is particularly for areas with high humidity or coastal areas.

- Regulatory compliance – compliance with local electrical codes and safety regulations is a critical factor affecting the market for alley arms.