A top tie is a head tie or head spacer used to support the electrical conductors that carry the electrical power. It helps maintain proper spacing and alignment of the conductors to ensure they remain securely in place. It also helps prevent swaying or vibrating excessively due to wind or other external factors. Top ties are from durable materials such as steel, aluminum or other corrosion-resistant alloys. These materials help them withstand the diverse climate conditions in Southeast Asia. Common types of top ties include standard top tie, vibration dampening, swivel, adjustable and heavy-duty top tie. They find use in application such as transmission lines, distribution system, multi-phase, telecommunication lines and substations. This guide will give details that ensure the best selection and performance of top ties in various applications.

Key features of top tie

Top ties have different features that help them ensure safety and reliability of the transmission lines. The specific features depend on design and intended application of the top tie. These features should align with the specific requirements of the transmission system. The following are the key features of the top tie as used in overhead transmission lines.

- Corrosion resistance – these top ties have coatings or materials that provide corrosion resistance. This makes them suitable for use in coastal areas or other environments with high humidity.

- Adjustability – some top ties allow flexibility in accommodating various conductor sizes and configurations.

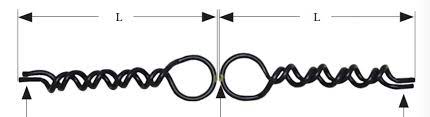

- Vibration dampening – features such as dampers or insulating materials can reduce conductor vibrations.

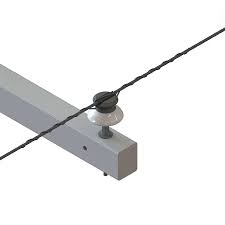

- Ease of installation – top ties allow utility workers to securely attach conductors to towers.

- Durability – they are from durable materials to ensure the top tie can withstand environmental stresses and loads.

- Load bearing capacity – top ties should support the weight and tension of conductors, insulators and other hardware components.

- Insulation capability – they include insulators to electrically isolate conductors from supporting structures. This helps reduce the risk of electrical interference and maintaining safety.

- Swivel mechanisms – swivel top ties can rotate to allow conductors to align with the direction of the wind. This minimizes wind induced stresses and sway.

Selection and installation of top tie

Selection of top ties include considering several factors. These factors help to ensure safety, reliability and compliance. These factors include type of application, voltage level, corrosion resistance, load capacity, insulation and cost effectiveness. The installation involves securing the electrical conductors and insulators. Additionally, it is advisable to consult with industry professionals for guidance on installation. The following is a basic installation guide for the top tie.

- Safety precautions – ensure proper use of safety gear including gloves, safety glasses and a helmet.

- Preparation – assemble all the components to use during the installation.

- Positioning – place the prepared top tie at the desired location on the conductor. Also, ensure proper alignment and orientation on the suport structure.

- Attachment – securely attach the top tie to both the conductor and the tower. This is through the use of fasteners such as bolts, nuts and washers.

- Tightening – tighten the fasteners to the recommended torque specifications. This is through the use of a torque wrench as recommended by the manufacturer.

- Alignment and spacing – verify that the conductors is correctly spaced and aligned within the top tie.

- Safety checks – conduct a visual inspection to confirm all components are securely fastened and there are no loose parts.

- Final adjustments – make any necessary adjustments to maintain proper conductor spacing and alignment.

- Documentation – keep records of the installation including the type and quantity of top ties used.

Maintenance and inspection of top tie

Proper maintenance and inspection ensure continued performance, safety and reliability. It also helps identify and address potential issues before they lead to system failures. Additionally, maintenance and inspection reduce the risk of costly failures. The following is a basic guide to the maintenance and inspection of top ties in Southeast Asia.

- Conduct visual inspections of all top ties in the transmission system and look for signs of wear, corrosion or damage. Check for loose of missing fasteners and tighten them to the recommended torque specifications.

- Examine conductor alignment and spacing within the top tie. This is to ensure it complies with design specifications.

- Schedule periodic maintenance of top ties to address issues found during inspections. Replace any damaged or corroded components to prevent further deterioration.

- Lubricate moving parts such as swivel mechanisms to maintain their functionality.

- Check for corrosion and apply extra protective coatings or materials as needed. Check for signs of degradation and consider applying UV-resistant coatings.

- Conduct specialized testing such as ultrasonic testing to detect hidden defects.

- Develop a routine inspection schedule based on the specific environmental conditions. This also depends on operational demands of the system.

- Maintain detailed records of maintenance activities. This includes inspection dates, findings, repairs and replacements.

Comparative analysis for top tie as used in overhead transmission lines

A comparative analysis of top ties involves assessing various factors to determine which type is most suitable. The selection should align with the specific requirements of the transmission system. These include environmental conditions, voltage levels, conductor configurations and load-bearing needs. The following are the common factors to include in the comparative analysis for top tie in Southeast Asia.

- Material and durability – materials such as steel, aluminum and other corrosion-resistant alloys offer durability and load-bearing capacity.

- Corrosion resistance – consider the level of corrosion resistance needed. This depends on the environmental conditions of the installation site.

- Load capacity – assess the load bearing capacity of top ties to ensure they can support the weight and tension of the conductors.

- Adjustability – they should allow flexibility in accommodating different conductor sizes and configurations.

- Insulation capability – check whether insulation is necessary to electrically isolate conductors.

- Vibration dampening – consider top ties with vibration dampening features. These features may include dampers or insulating materials.

- Swivel mechanisms – they also allow conductors to align with the winds direction to reduce wind induced stresses and sway.

- Compliance with standards – confirm the top ties follow the relevant industry standards and regulations. This helps to ensure quality, safety and performance.

- Ease of installation – consider whether the top tie is easy to install to save time and labor during installation and maintenance.

Certifications and standards in Southeast Asia

There are various certifications and standards in Southeast Asia. These standards are relevant to top ties used in transmission lines. They help to ensure safety, quality and compliance with regional regulations. Additionally, it is advisable for manufacturers to collaborate with reputable suppliers. They should provide certifications and compliance documentation. The following are the common standards and certifications for top ties in Southeast Asia.

- IEC standards – these are standards for electrical and electronic technologies for global best practices.

- ASTM standards – this provides standards for various materials and products used in the construction and maintenance of electrical infrastructure.

- ISO certification – this offers certification for quality management systems. They also help to demonstrate their commitment to quality.

- Local and national standards – each country in Southeast Asia has their own set of rules and standards. Manufacturers should ensure the top ties comply with the specific standards in the region.

- Environmental certifications – these certifications ensure the top ties reduce environmental impact in sensitive areas.

Regional market for top tie in Southeast Asia

Top ties in Southeast Asia experiences various changes from different factors in the market. These factors lead to the increased demand for reliable electrical transmission networks. Also, manufacturers and suppliers should stay attuned to market trends and regulatory changes for success. The following are the factors that shape the industry in Southeast Asia.

- Telecommunication infrastructure – the growth of the infrastructure in the region requires the installation of antennas and communication equipment.

- Local manufacturing – some of the countries have local manufacturing capabilities for top ties. This is beneficial to projects that require local expertise, customization and support.

- Competitive market – the competition is from local and international manufacturers that offer a range of products.

- Economic factors – economic conditions, government policies and infrastructure investment play a significant role in shaping the demand for top ties.

- Multi-phase transmission – top ties can help maintain proper phase separation. This is in high-voltage and extra high-voltage transmission systems.

- Coastal regions – top tie with corrosion-resistant properties is in demand in these coastal regions to ensure long-term performance.

- Growing energy demand – expansion and upgrading of the infrastructure helps to meet the increased energy demand. This also increases the demand for top ties for use in these projects.