No wrench screw anchors work in power transmission lines to provide stability and secure the guy wires. They involve a steel shaft with helical blades that twist to the ground to provide stability. The no wrench screw anchors have different designs and mechanisms that allow for installation without the need for extra tools or wrenches. No wrench screw anchors are from hot dip galvanized steel with an upset hex for guying purposes. The anchor is from durable materials that enhance corrosion resistance and longevity of the anchor.

Components of no wrench screw anchors

No wrench screw anchors have a design that allow them to work without the need of wrenches or other tools. The various designs of the anchors depend on the manufacturer and the soil conditions in the area of installation. The following are the main components that work together to ensure operability.

- Shaft -this is a steel rod that forms the main body of the anchor. This allows for easy installation without the need for wrenches or extra tools.

- Helical plates – helical plates resemble the wings of a screw that provide the anchor with its holding capacity and resistance against uplift forces.

- Drive head – the drive head allows for hand-driven or lightweight equipment-driven installation. The drive heads also eliminate the need for traditional wrenches. This enables a quick and tool-free installation process.

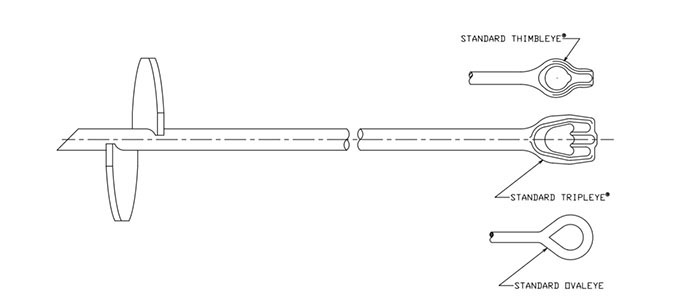

- Attachment point – the upper end of the no wrench screw anchor has an attachment point like an eye or head that connects the guy cable.

Types of screw anchors used on power transmission lines

Types of screw anchors vary depending on their design, size and application. The types also vary depending on the manufacturer, load requirements and soil conditions. The common types of o wrench screw anchors include:

- Single helix screw anchor – this anchor has a single helical plate or blade welded to the shaft. It works for various applications with moderate load capacities. This may include areas with temporary structures, soil erosions or small-scale projects.

- Double helix screw anchor – double helix screw anchors feature two helical plates spaced along the shaft.. This is to provide increased load-bearing capacity and stability. They are mostly used in applications where higher load capacities are necessary.

- Triple helix screw anchor – triple helix screw anchors have three helical plates positioned along the shaft. This enhances load-bearing capacity and provides increased stability in challenging soil conditions. They work in applications that require exceptional load resistance. This includes heavy duty structures or critical infrastructure projects.

Applications of no wrench screw anchors

There are various applications of no wrench screw anchors in the industries. The type used depends on the load requirements, soil conditions and regulations for each project. The following are the main application areas of no wrench screw anchors.

- Temporary structures – the anchors work in the installation of temporary structures like tents, canopies, event stages and temporary signage. They provide quick and easy anchoring solutions that can recycle and reused as needed.

- Soil erosion control – the anchors work in soil control measures like stabilization of slopes, embarkments and retaining walls.

- Guy wire anchors – the anchors work in utility and telecommunication industries for anchoring guy wires that support poles, towers and antennas.

- Construction foundation – the anchors work as foundation solution for small-scale structures like decks, sheds and small buildings. They are cost effective and time-efficient alternative to traditional concrete footings.

- Dock and marine applications – the anchors work in dock and marine applications. This is to secure floating docks, boat lifts and other waterfront structures. The stability ensures they resist the forces exerted by waves, tides and currents.

- Environmental monitoring equipment – the anchors can secure the environmental monitoring equipment like weather stations, groundwater monitoring wells or wildlife cameras. They ensure stability and prevent displacement or damage to the monitoring devices.

Installation process of no wrench screw anchors

Installation process of no wrench screw anchors may vary depending on the specific type, size and manufacturer’s instructions. Additionally, it is advisable to consult with anchor manufacturers, suppliers or experienced professionals. They help to get detailed instructions and recommendations for specific product and project and requirements.

- Prepare the site by determining the precise location where the anchor will install. Clear the area of any obstacles, debris or vegetation that may interfere with the installation.

- Mark the anchor placement by using marking flags to indicate the exact placement points for the screw anchors.

- Prepare the tools according to the manufacturer’s instructions which include handheld driving tools. Lightweight equipment or specific drive heads.

- Position the drive head onto the anchor shaft, apply downward pressure on the anchor into the soil using the designated equipment.

- Conduct load tests to determine the load-bearing capacity of the installed anchor.

- Inspect the installed anchors for any signs of movement, corrosion or damage. Perform routine maintenance and any necessary adjustments to ensure the ongoing stability and performance of the anchors.

How to select the best screw anchor

The selection process of the no wrench screw anchors depends on various factors. These include load requirements, soil conditions and the preferred installation method. Also, you should consult with professionals, experts and manufacturers of the anchorsfor guidance on the most appropriate anchors for our project. The following are the key factors to consider to select the best anchors.

- Consider the cost effectiveness of the screw anchor wile keeping in mind the importance of quality and performance. Compare prices of different anchors and weigh them against their features.

- Research the reputation of the manufacturer who should have a track record for producing high quality no wrench screw anchors.

- Ensure the selected anchors meet the industry standards and any other relevant regulations for your specific application.

- Determine whether you require a manual installation anchor if machine-driven installation is possible or preferred.

- Consider the diameter and length of the anchor shaft and the size of the helical blades. The size should be appropriate for the intended load and soil conditions.

- Evaluate the soil conditions at the installation site including soil type, moisture content and stability.

- Determine the anticipated load or tension that the screw anchor will need to withstand. The load capacity should exceed your projects requirements to ensure stability and safety.