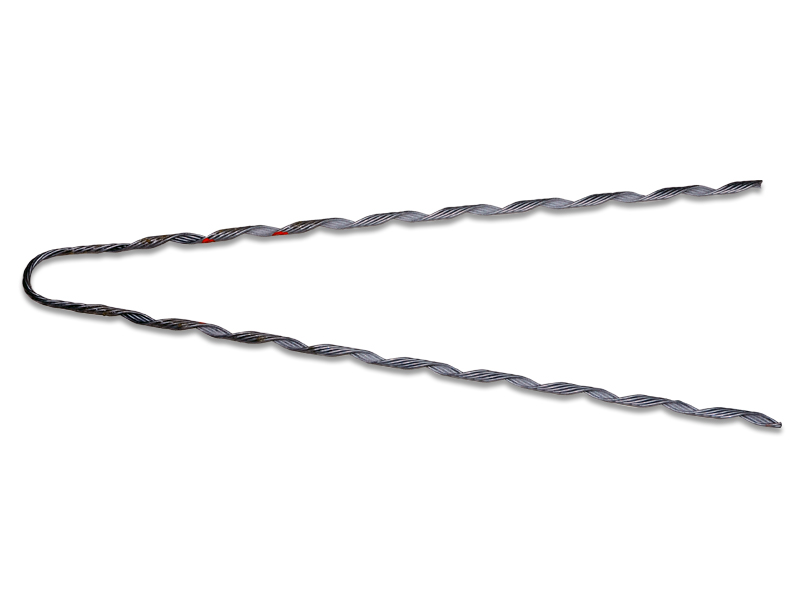

A false dead end is a component that mock the appearance of dead ends used as termination points for conductors. They serve a specific purpose in certain situations and applications. False dead ends are also known as false terminations or mock dead ends. They help used to provide mechanical support or termination functionality as actual dead ends. False dead ends are visual components used for specific purposes. Do not be mistake them for the proper termination points for conductors in transmission line applications. The common uses of the false dead ends include visual deterrence preventing birds from perching, conductor tensioning and line testing maintenance.

Components of the false dead ends

False dead ends do not serve the same mechanical or electrical functions as actual dead ends for terminating conductors. They are components with a specific purpose and are not intended for use as structural or electrical terminations. The following are the components of the false dead ends.

- False dead-end body – the main component is the false dead-end body made of a non-conductive material. The body mimics the appearance of an actual dead end with similar shape and size.

- Fastening hardware – false dead ends work with fasteners to secure them to the conductor.

- Insulating hardware – false dead end requires insulating hardware to ensure electrical insulation between the conductor and the false dead-end body.

- Anchoring points – false dead ends may have anchoring points or eyelets were ropes, safety lines or pulleys can attach. They provide safe working conditions for line testing, maintenance or bird deterrent devices.

- Visual features – false dead ends include features that mimic the appearance of actual dead ends to create the desired visual deterrent effect for birds.

Types of false dead ends

There are various types of false terminations for overhead transmission lines. The specific types of false dead end available varies depending on the manufacturer or the supplier. The following are the types of false dead end for the overhead lines.

- Bird deterrent false dead ends – these dead ends help to deter birds from perching on the power line conductors. They feature visual elements like spikes, reflective materials or deterrent shapes that create an obstacle for birds.

- Mock dead end structures – these are false dead ends that mimic the appearance of actual dead ends used for conductor termination. They provide a visual representation of a dead end but do not function as actual terminations.

- Deception false dead ends – deception false dead ends are false terminations for security purposes. The design is to deceive and deter unauthorized access to the transmission line by creating the appearance of live terminations.

- Temporary anchoring false dead ends – these false dead ends serve as temporary anchoring points for ropes, safety lines or pulleys during maintenance or tensioning operations.

- Visual indicator false dead ends – hese are help to provide a visual indication or marking along the transmission line. They highlight specific points, landmarks or clearance zones along the route for maintenance or navigational purposes.

Application areas of the dead end

It is important to consider the specific objectives, requirements and constraints of the power transmission line project when determining the application of false dead ends. Discussed below are the main applications of the false dead ends.

- Maintenance and safety – false dead ends can serve as temporary anchoring points during maintenance activities on the transmission line. They also provide secure attachment points for safety ropes, pulleys or ladders. This allows the maintenance crew to access and work on the line safety.

- Bird deterrence – the primary application of the false dead ends is to deter birds from perching or nesting on the power line conductors. They help reduce the risk of bird related issues like electrocution or damage. This is mostly from nesting materials, improving the reliability and safety of the power transmission line.

- Historical preservation – false dead ends help in aesthetic purposes in presence of old or traditional dead ends. They may have cultural significance.

- Temporary marking or identification – the dead ends can work as temporary indicators along the transmission line. They provide a visual reference for personnel working on the line.

- Visual obstacle – false dead ends can work to create visual obstacles along the transmission lines to indicate clearance zones. They also improve safety by visually guiding personnel or signaling areas that require caution.

Installation process of the false dead ends

Every installation process varies depending on the design, manufacturer recommendations, conductor type among other factors. Additionally, always consult with professionals experienced in installation if in doubt for proper installation. The following is a series of steps to follow during the false dead-end installation.

- Assess the specific requirements and objectives for installing false dead ends. Determine the location along the transmission line where the visual deterrent points are necessary.

- Select false dead ends that are suitable for the conductor size, shape and purpose of the installation for compatibility.

- Prepare the conductor by cleaning the cleaning the surface and removing any debris or contaminants. These may hinder proper attachment of false dead ends.

- Attach the false dead ends securely to the conductor according to the manufacturer’s instructions by use of fasteners.

- Ensure proper electrical insulation between the conductor and the false dead-end body. Use insulating hardware like insulators, bushings or other suitable components.

- Ensure that they have anchoring points during tensioning or maintenance activities if applicable.

- Verify that the false dead ends properly attach and are secure to provide the desired visual effect or temporary anchoring functionality. Also perform any tests and inspections to ensure the reliability and effectiveness of the false dead ends.

- Maintain proper documentation of the false dead-end installations, including the location, date of installation or other observations.

Choosing the best dead ends

Before any purchase of false dead ends, you should consider various factors to help make an informed decision for your requirements. The following are the factors to consider when selecting.

- Determine the purpose of the false dead end.

- Ensure the false dead end is compatible with the conductor size, type and existing infrastructure.

- Evaluate the effectiveness of the false dead-end design in deterring birds if that’s the intended use.

- Assess the durability and longevity of the false dead end and ability to withstand environmental conditions.

- Consider the ease of installation.

- Evaluate the maintenance requirements of the false dead ends. They include periodic inspections, cleaning or repairs.

- Ensure the selected false dead end complies with relevant industry standards, regulations and safety guidelines.

- Consider the reputation and reliability of the manufacturer. They should have a track record of producing high quality false dead ends.

- Evaluate the cost effectiveness of the dead ends by comparing features, prices and performance.