A rock anchor is a type of anchoring system used to secure and stabilize structures in rocky terrain. The main purpose of rock anchors is to provide extra support. It helps prevent movement of structures in areas with traditional foundation methods. It comprises of high strength steel cables installed into stable soil beneath the surface. This helps them to adapt to various environmental conditions South America. The design and installation of rock anchors take into account geotechnical considerations. This is including the characteristics of the rock and the load bearing capacity. Type of rock anchors include mechanical rock anchors, grouted rock anchors, drilled-in rock anchors and expansion shell rock anchors. They find use in various applications such as stabilizing of slopes, retaining wall, tunnelling, transmission tower foundations and hydroelectric power projects.

Key features of rock anchor

Rock anchors have various features that provide stability and reinforcement. They also support applications in challenging geological conditions. They also help to make them suitable choices in the industry. The following are the key features of the rock anchors.

- High-strength materials – the high strength materials help to ensure the anchors withstand significant loads. This provides a reliable support in demanding conditions.

- Versatility – rock anchors adapt to different applications and geological conditions. They are suitable in specific situations. These include mechanical, grouted, tensioned or post tensioned anchors.

- Adjustable length and tension – adjustability in length and tenson allows for precise control during installation. It also helps ensure proper load distribution in the transmission lines.

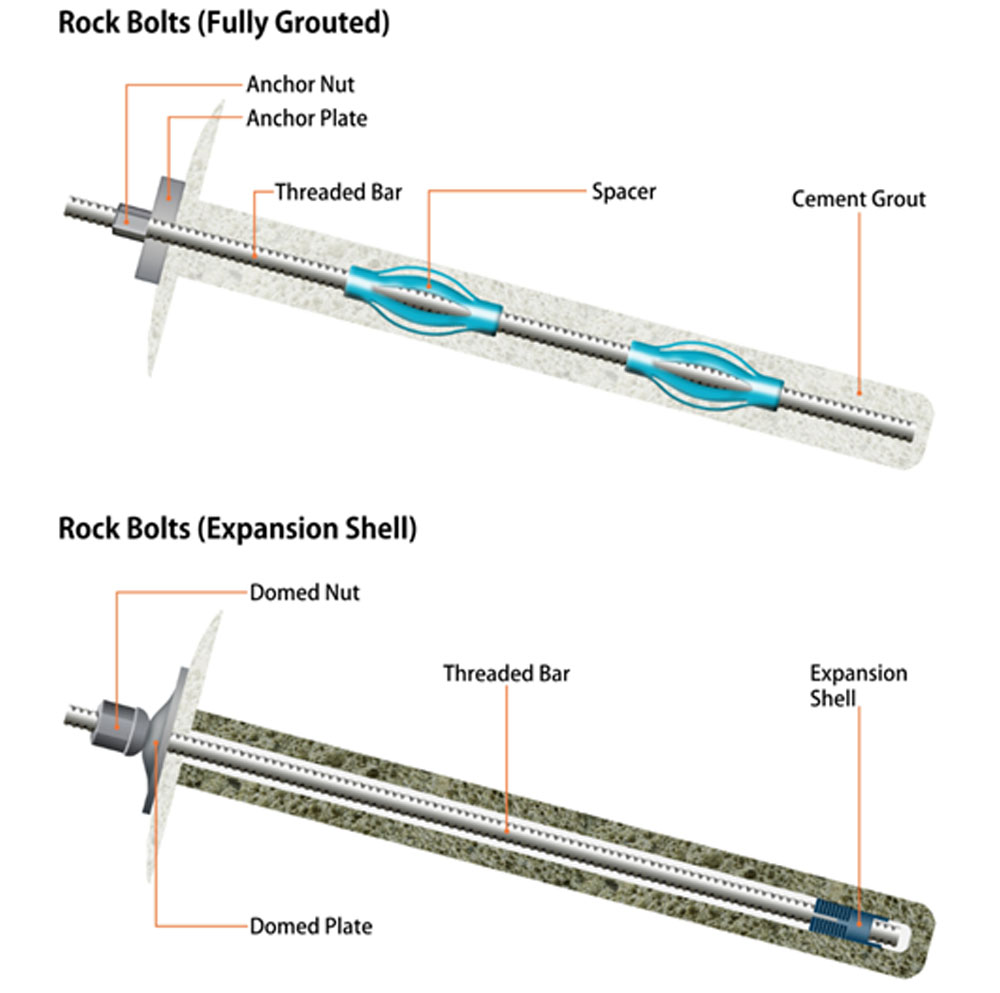

- Grouting system – this involves injecting a cementitious grout into the borehole. This is to enhance the bond between the anchor and the rock. This is to provide additional stability.

- End termination – these help to securely connect the anchor to the structure it supports. These include anchor plates, nuts and other hardware that facilitate the transfer of loads.

- Durability – rock anchors are able to withstand exposure to environmental factors. This is including weather conditions and geological forces.

- Corrosion resistance – coatings help to enhance their durability in environments with high levels of moisture.

- Load capacity – the rock anchors are able to handle specific loads. This is depending on factors such as the weight of structure, environmental forces and geological conditions.

Selection and installation of rock anchor

Proper selection of rock anchors helps to ensure they meet the specific requirements of the project. It includes considering various factors such as geological conditions, loads requirements, types of rock anchors, corrosion resistance and grouting system. The installation of rock anchors requires use of suitable equipment. The following is a general installation process of the rock anchors.

- Site investigation – conduct a thorough site investigations to understand the geological conditions. This includes drilling exploratory boreholes, assessing rock quality and identifying potential challenges.

- Design and engineering – develop a detailed design for the rock anchors based on the site investigation and project requirements. This includes anchor type, length and load capacity.

- Drilling – drill boreholes into the rock according to the design specifications. The diameter and depth of the holes depends on the type of anchor and load bearing capacity required.

- Cleaning and flushing – clean the boreholes to remove loose debris and cuttings. Flush with water to ensure the holes are clear and ready for anchor installation.

- Installation of anchor – depending on the type or rock anchors influences the installation process. Insert the anchor into the drilled hole and expand the anchor to secure it in place. For grouted anchors, place the anchor in the hole and inject grout to fill the annular space between the anchor and the rock. For tensioned anchors, install the anchor and tension the anchor to the specified load.

- Grouting – inject the specified grout material into the borehole to provide additional support. This help improves the load transfer between the anchor and the rock.

- End termination installation – attach the end termination to the exposed end of the anchor. This helps to facilitate the transfer of loads between the anchor and the supporting structure.

- Testing – conduct tests to verify the performance of the installed anchors. This includes load testing, torque testing or other relevant tests. This is to ensure the anchors meet design specification.

- Documentation – maintain detailed records of the installation process. This includes drilling logs, dates, and types of rock anchors.

Maintenance and inspection of rock anchor

Proper maintenance and inspection help to ensure their long-term performance and structural integrity. It also helps to identify potential issues, prevent failures and extend the lifespan of the rock anchors. It also helps to ensure the continued reliability and safety of rock anchors in various applications. Additionally, it is important to conduct regular professional assessments for effectiveness. The following is a general guide on the maintenance and inspection of rock anchors in rock anchors in South America.

- Conduct regular visual inspections of the exposed portions of the rock anchors. Check for signs of corrosion, damage or any visible abnormalities.

- Ensure the inspection points are easily accessible to remove any obstacles. This may obstruct a clear view of the anchor components.

- Inpect end termination for signs of wear, corrosion or any deformation. Ensure the nuts, plates or other termination components.

- Check for any signs of grout loss, crack or deterioration in the grouted region to prevent further degradation.

- Periodically conduct load testing to verify that the anchors can still support the specified loads. this involves applying incremental loads and monitoring anchor responses.

- Consider using non-destructive testing methods such as ultrasonic testing or magnetic particle testing.

- Check the effectiveness of corrosion protection measures and inspect coatings, sacrificial anodes and other corrosion resistant features.

- Instrument corrosion control measures to protect the anchors. This includes applying corrosion resistant coatings and corrosion inhibitors.

- Control vegetation around anchor installations to prevent roots from affecting the stability of the anchor.

- Update and maintain records of all maintenance activities, inspections and any repairs made to rock anchors.

Comparative analysis of rock anchors in South America

Conducting a comparative analysis involves evaluating and assessing different types of rock anchors. This includes factors such as performance, installation requirements, durability and cost. It helps to select rock anchors depending on the geological conditions and specific requirements to the project. The following are the key factors to include in a comparative analysis in South America.

- Load capacity – the selected rock anchors should provide higher load capacities.

- Installation complexity – check the ease of installation to reduce repair and downtime. Mechanical anchors are simpler to install.

- Versatility – consider the ability of the anchors to find use in various applications. Grouted rock anchors and mechanical anchors are suitable for a range of geological conditions.

- Adjustability – proper adjustability allows for precise load control especially for tension.

Certifications and standards in South America

The certifications and standards for rock anchors vary depending on country, region and specific application. These standards help to govern the use and availability of rock anchors in the industry. The following are the certifications and standards in South America.

- ISO standards – these are international standards for geotechnical investigation and testing. It provides rules for testing geotechnical structures including rock anchors.

- European standards – these are European standards which specifies the execution of ground anchor projects. This includes testing and documentation and testing.

- National standards and regulations – each south American country has their own set of standards and regulations for the use of rock anchors. They are present in countries such as Brazil, Argentina and Chile.

- IGS guidelines – these are guidelines for geosynthetics and geotechnical engineering for rock anchors.

Regional market for rock anchors in South America

Market conditions and dynamics may influence the regional market for rock anchors in South America. These conditions change overtime and it is advisable to consult industry reports, market studies and local business sources. The following are the various market dynamics that influence the regional market for rock anchors in South America.

- Geological conditions – the geological characteristics of the region play a crucial role in the use of rock anchors.

- Construction regulations and standards – various regulations in the region also influence the use of rock anchors.

- Economic factors – factors like GDP growth, investment trends and government spending on infrastructure influences the demand for rock anchors.

- Technological advancements – innovations and advancements in rock anchor technology impacts the market trends.

- Competitive landscape – presence of manufacturers, suppliers and distributors of rock anchors in the region also influence the market.

Frequently asked questions

A rock anchor is a type of anchoring system used to secure and stabilize structures such as transmission poles. They help provide extra support and prevent movement of the structures in areas where traditional foundation methods are impractical.

Specific choice of rock anchors depends on the assessment of the geological conditions in the region. Common types include friction anchors, grouted anchors, mechanical anchors and wedge anchors.